Silver plating solution for chemical silvering of polyester fabrics, silver plating method of silver plating solution and anti-tarnishing protection method of plating layer

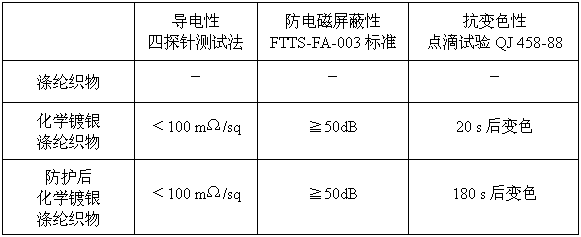

A polyester fabric, chemical silver plating technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of affecting product performance, not widely recognized, electrical conductivity, etc., to achieve excellent anti-electromagnetic shielding performance, improve anti-discoloration Good performance and anti-discoloration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The base material of embodiment is polyethylene terephthalate (PET) polyester fabric, and concrete implementation steps are as follows:

[0038] The first step, washing and degreasing, washing powder 2 g / L, temperature 80 O C, time 30 minutes;

[0039] The second step, roughening, put the washed and degreased polyester fabric into the roughening solution for roughening. The composition of the roughening solution is: sodium hydroxide 200 g / L, temperature 80 O C, time 30 minutes;

[0040] The third step, sensitization, immerses the roughened polyester fabric in the sensitization solution, 20 g / L SnCl 2 , 20 mL / L concentrated HCl, temperature 30 O C. Rinse slowly with running water for 10 minutes;

[0041] The fourth step, activation, immerse the sensitized polyester fabric in the activation solution, 0.3 g / L PdCl 2 , 4 mL / L concentrated HCl, temperature 30 O C. Rinse slowly with running water for 10 minutes;

[0042] The fifth step, electroless silver plating after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com