Antibacterial finishing method for textile containing cellulose

A technology of cellulose fiber and antibacterial finishing, which is applied in fiber treatment, textile and papermaking, plant fiber, etc., to reduce irritation, prolong action time and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

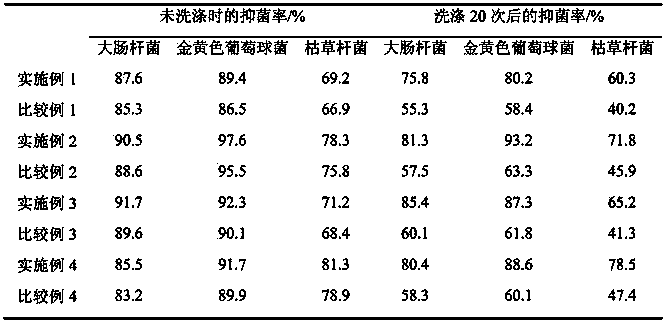

Examples

Embodiment 1

[0026] (1) Add 1g of honeysuckle extract to 50mL sodium alginate solution with a mass fraction of 2%, and stir well. At a height of 10 cm from the liquid surface, use a No. 5 needle to mix sodium alginate and honeysuckle extract, and under magnetic stirring, drop by drop at a constant speed 1% CaCl 2 solution, after continuing to stir for 0.5 h, the gel microspheres were filtered out, washed 3 times with distilled water, and set aside. Chitosan (molecular weight 0.5×10 5 , the degree of deacetylation is 75%) was dissolved in 0.5% acetic acid solution by volume fraction to make a chitosan solution with a mass fraction of 1.5%. The capsules were collected by suction filtration, washed 3 times with distilled water, dried on the surface of the capsules with filter paper, and stored in a refrigerator at 4°C until use.

[0027] (2) Soak 5g of pure cotton fabric in a caustic soda solution with a mass fraction of 10%, and soak it for 15 minutes at 35°C, then take out the fabric, put...

Embodiment 2

[0032] (1) Add 1g of aloe vera extract to 100mL of sodium alginate solution with a mass fraction of 4%, and stir well. At a height of 10cm from the liquid surface, use a No. 5 needle to mix sodium alginate and traditional Chinese medicine extracts, and under magnetic stirring, drop 3% CaCl with a mass fraction of 3% at a constant speed. 2 solution, after continuing to stir for 1.5 h, the gel microspheres were filtered out, washed 5 times with distilled water, and set aside. Chitosan (molecular weight 3.5×10 5 , the degree of deacetylation is 70%) was dissolved in 2% acetic acid solution by volume fraction to prepare a chitosan solution with a mass fraction of 3%, then the gel microspheres were added to the chitosan acetic acid solution, stirred by magnetic force for 2 hours, and pumped The capsules were collected by filtration, washed 5 times with distilled water, dried on the surface of the capsules with filter paper, and stored in a refrigerator at 4°C until use.

[0033] ...

Embodiment 3

[0038] (1) Add 1g of mugwort leaf extract to 80mL of sodium alginate solution with a mass fraction of 2.5%, and stir well. At a height of 10cm from the liquid surface, use a No. 5 needle to mix the sodium alginate and Artemisia argyi leaf extract, and add 2% CaCl drop by drop at a constant speed under magnetic stirring. 2 solution, after continuing to stir for 1 h, the gel microspheres were filtered out, washed 4 times with distilled water, and set aside. Chitosan (molecular weight 1.5×10 5 , the degree of deacetylation is 65%) was dissolved in 1% acetic acid solution by volume fraction to prepare a chitosan solution with a mass fraction of 2.5%. The capsules were collected by filtration, washed 4 times with distilled water, dried on the surface of the capsules with filter paper, and stored in a refrigerator at 4°C until use.

[0039] (2) Soak 5g of viscose fabric in a caustic soda solution with a mass fraction of 20%, and soak it for 30 minutes at 30°C, then take out the fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com