Preparation method for polyacid @ MIL-101 composite material and application of polyacid @ MIL-101 composite material

A composite material, polytungstate technology, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve the problem of polyacid shedding, low specific surface area, affecting the interaction between active sites and guest molecules and other problems, to achieve the effect of easy separation, stable structure and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

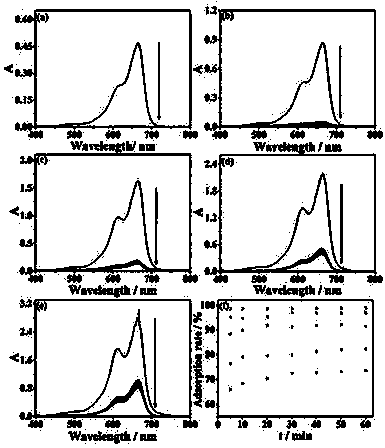

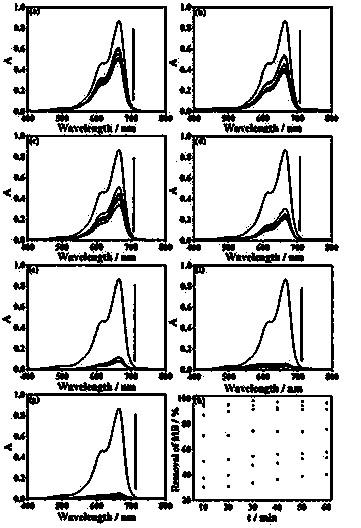

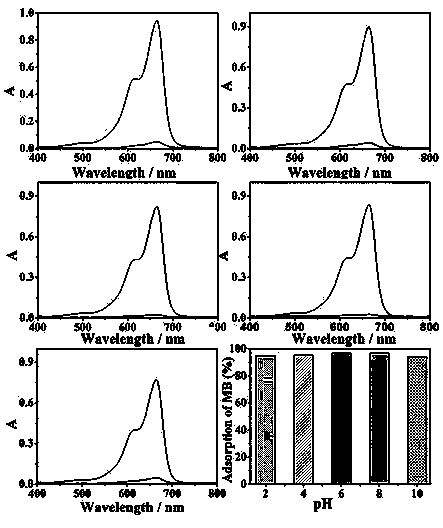

[0023] Example 1: Tetramethylammonium hydroxide (2.37 mmol), terephthalic acid (10 mmol), chromium nitrate (10 mmol) were dissolved in 50 ml deionized water successively, followed by 0.6-6.0 g K 4 PW 11 VO 40 Add it into the above solution and stir for 20 minutes, divide the above solution into 10 parts, transfer them to 20 mL autoclave respectively, react at 185°C for 3 days, and naturally cool to room temperature to obtain a green powder, which is PW 11 VMIL-101.

Embodiment 2

[0024] Example 2: Dissolve tetramethylammonium hydroxide (2.37 mmol), terephthalic acid (10 mmol), and chromium nitrate (10 mmol) in 50 ml deionized water, followed by 0.6-6.0 g H 3 PW 12 o 40 Add it into the above solution and stir for 20 minutes, divide the above solution into 10 parts, transfer them to 20 mL autoclave respectively, react at 180°C for 2 days, and naturally cool to room temperature to obtain a green powder, which is PW 12 MIL-101.

Embodiment 3

[0025] Example 3: Tetramethylammonium hydroxide (2.37 mmol), terephthalic acid (10 mmol), chromium nitrate (10 mmol) were dissolved in 50 ml deionized water successively, followed by 0.6-6.0 g K 4 SiW 12 o 40 Add it into the above solution and stir for 20 minutes, divide the above solution into 10 parts, transfer them to 20 mL autoclave respectively, react at 175°C for 3 days, and naturally cool to room temperature to obtain a green powder, which is SiW 12 MIL-101.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com