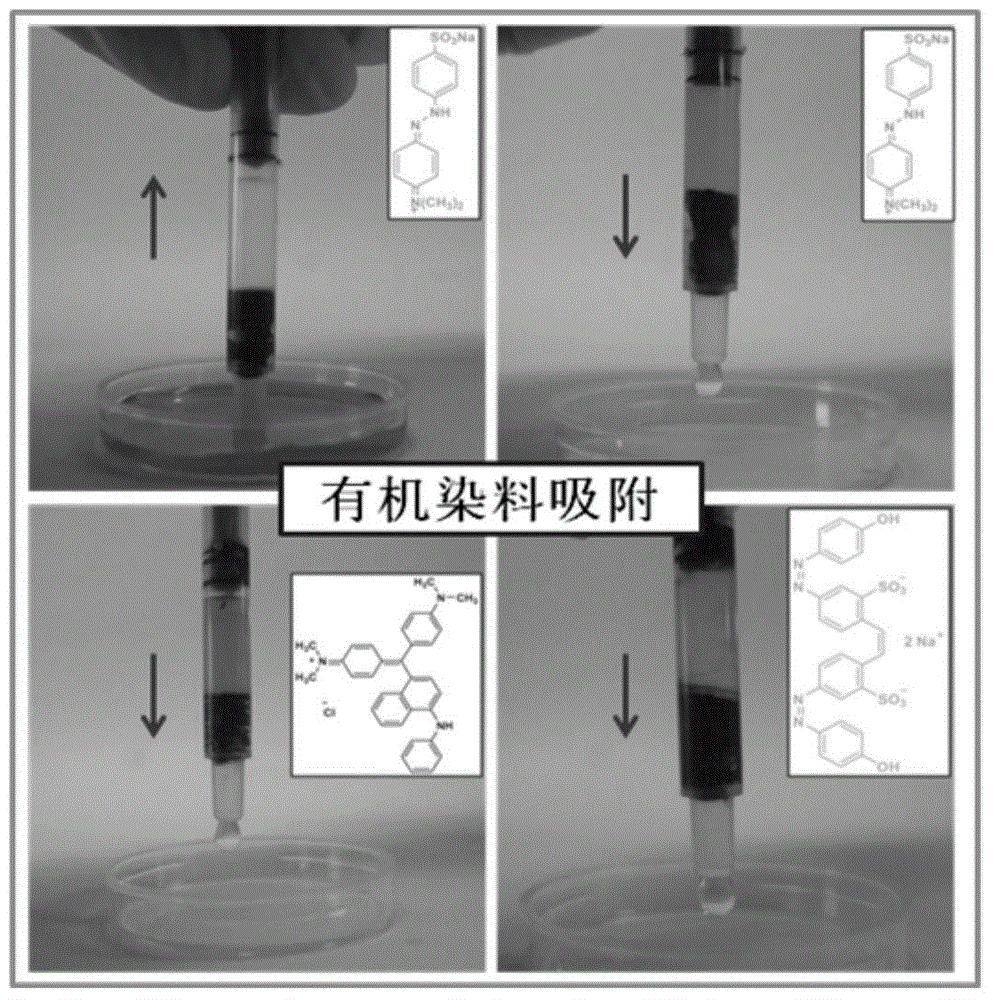

Elastic conducting polymeric hydrogel, sponge, preparation method and application thereof

A conductive polymer, hydrogel technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of not realizing the preparation of elastic conductive organic sponge, and achieve excellent compression and resilience performance, low cost, simple and easy raw materials the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

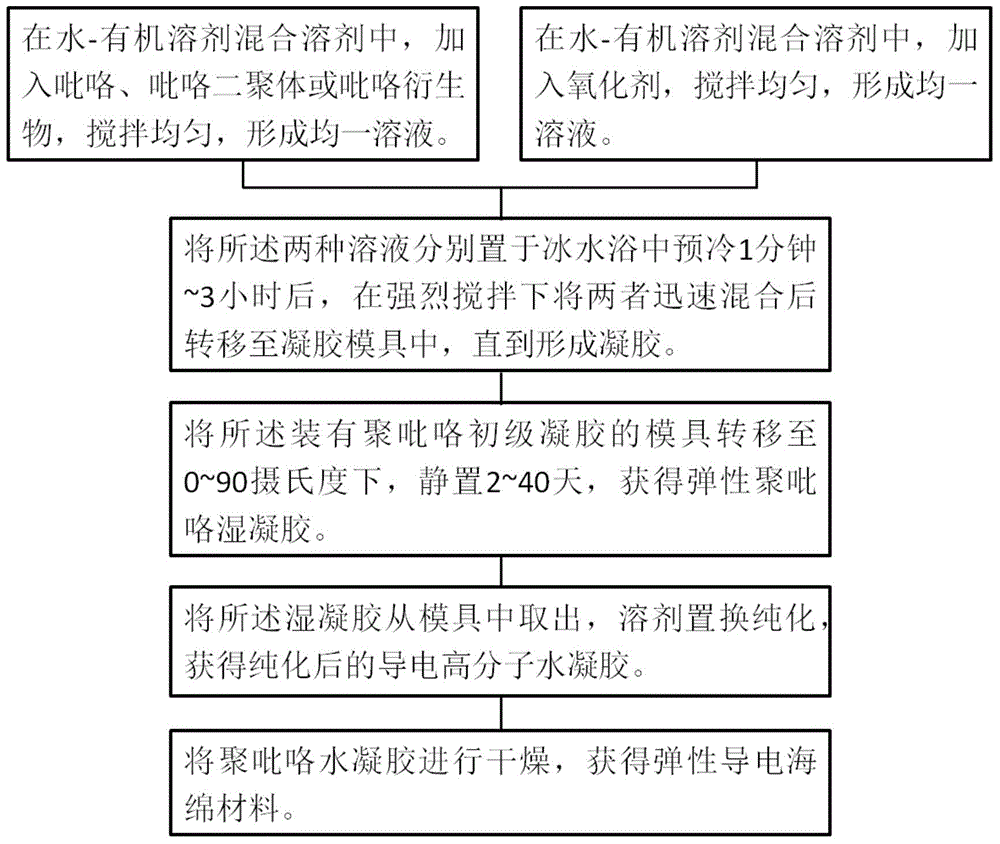

[0075] Still taking a preparation method of an elastic polypyrrole hydrogel as an example, the method is to prepare a highly elastic conductive polymer hydrogel through stage-by-stage kinetic control, see figure 1 , the method may include the following steps:

[0076] a. Adding pyrrole, pyrrole dimer or pyrrole derivative to the mixed solvent of water and organic solvent, stirring evenly, configuring monomer solution A;

[0077] Wherein, the organic solvent may be selected from but not limited to ethanol, ethylene glycol, glycerol, acetone, butanone, acetonitrile, tetrahydrofuran, N,N-dimethylformamide, N,N-dimethylacetamide , dimethyl sulfoxide, etc. The volume ratio of water and organic solvent in the mixed solvent is preferably 1 / 10-10 / 1, more preferably 1 / 5-5 / 1.

[0078] b. Dissolving the oxidizing agent in the same mixed solvent as solution A, and configuring the homogeneous solution B of the oxidizing agent;

[0079] Wherein, if the unimolecular composite oxidant is...

Embodiment 1

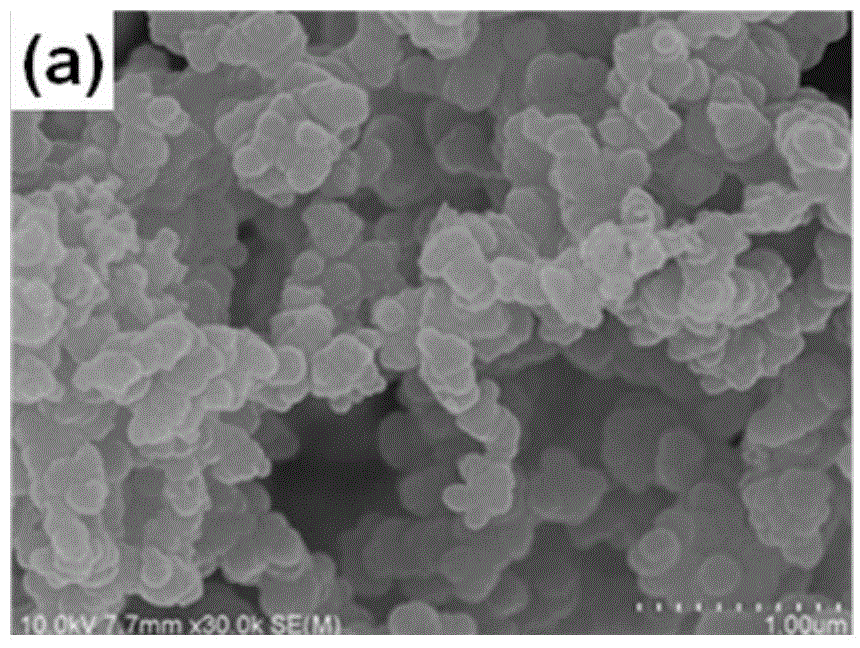

[0098] Example 1 see again figure 1 , Add 2.24 mmol, 155 μL of pyrrole (Pyrrole) monomer into 1.5 mL of water-dimethyl sulfoxide (v / v1:5) mixed solution, mix well and place in ice-water bath for 30 min. At the same time, 1.12mmol, 0.281g manganese nitrate tetrahydrate (Mn(NO 3 ) 3 4H 2 O) Dissolve in 1.5mL water-dimethylsulfoxide (v / v1:5) mixed solution, mix well and place in ice-water bath for 30min. Under strong magnetic stirring, the ferric nitrate solution was added to the pyrrole monomer solution, stirred evenly, transferred to a gel mold, and left to stand in an ice-water bath for about 2 hours to form a gel. Transfer it to a constant temperature water bath at 35°C and let it stand for 40 days. Take the obtained gel out of the reaction vessel, add 0.1mol / L hydrochloric acid aqueous solution to the wet gel, pour out the hydrochloric acid aqueous solution after soaking for 3 hours, repeat 8 times, add deionized water to the wet gel, soak for 3 hours Finally, deioniz...

Embodiment 2

[0099] Example 2 see again figure 1 , Add 6.26mmol and 433μL of pyrrole (Pyrrole) monomer into 3mL water-ethanol (v / v3:1) mixed solution, mix well and place in ice-water bath for 10min. At the same time, 12.52mmol, 5.06g iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) Dissolve in 3mL water-ethanol (v / v3:1) mixed solution, mix well and place in ice-water bath for 10min. Under strong magnetic stirring, the ferric nitrate solution was added to the pyrrole monomer solution, stirred evenly, and then transferred to a mold, and the reaction solution was allowed to stand in an ice-water bath for about 5 minutes to form a gel. It was transferred to a constant temperature water bath at 50°C and left to stand for 15 days. Take the obtained gel out of the mold, add 0.05mol / L hydrochloric acid aqueous solution to the wet gel, pour out the hydrochloric acid aqueous solution after soaking for 4 hours, repeat 6 times, add deionized water to the wet gel, soak for 4 hours Pour out the deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com