Method for preparing dye-sensitized solar cell module

A technology of solar cells and dye sensitization, applied in the field of solar cells, to achieve the effects of easy operation, maintaining long-term stability, and improving long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

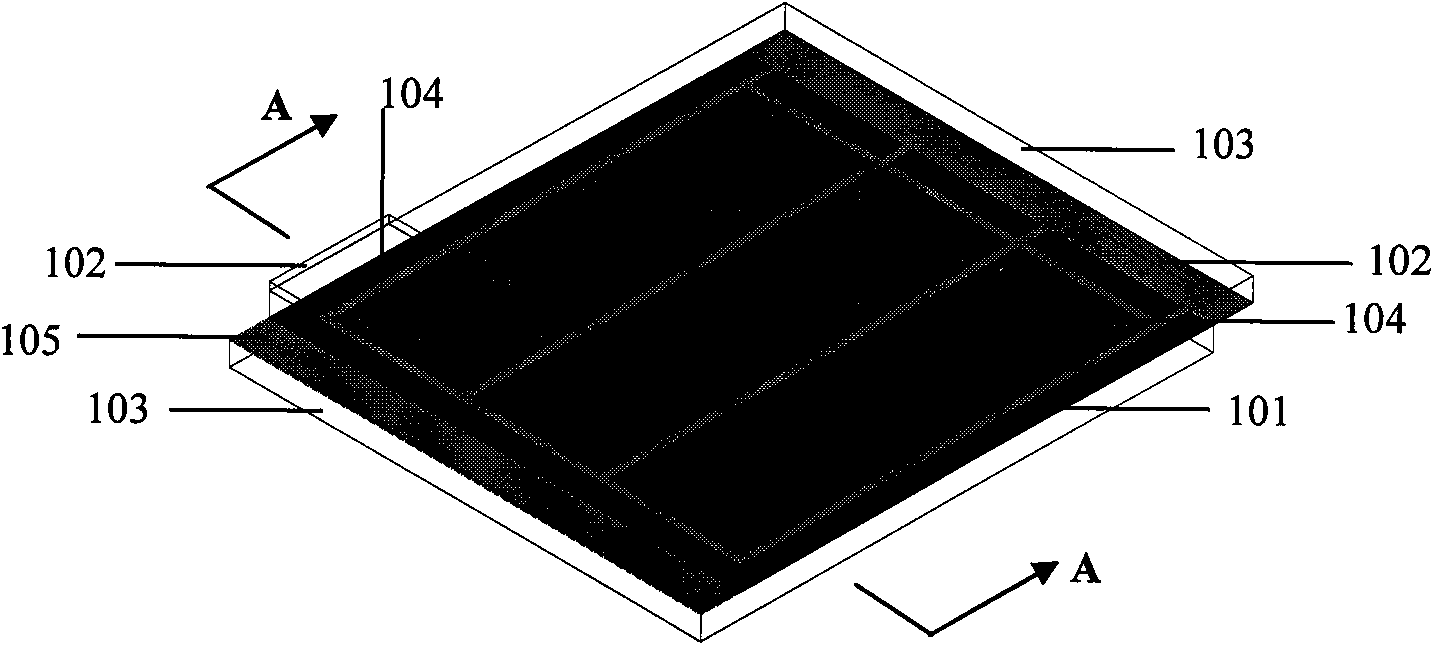

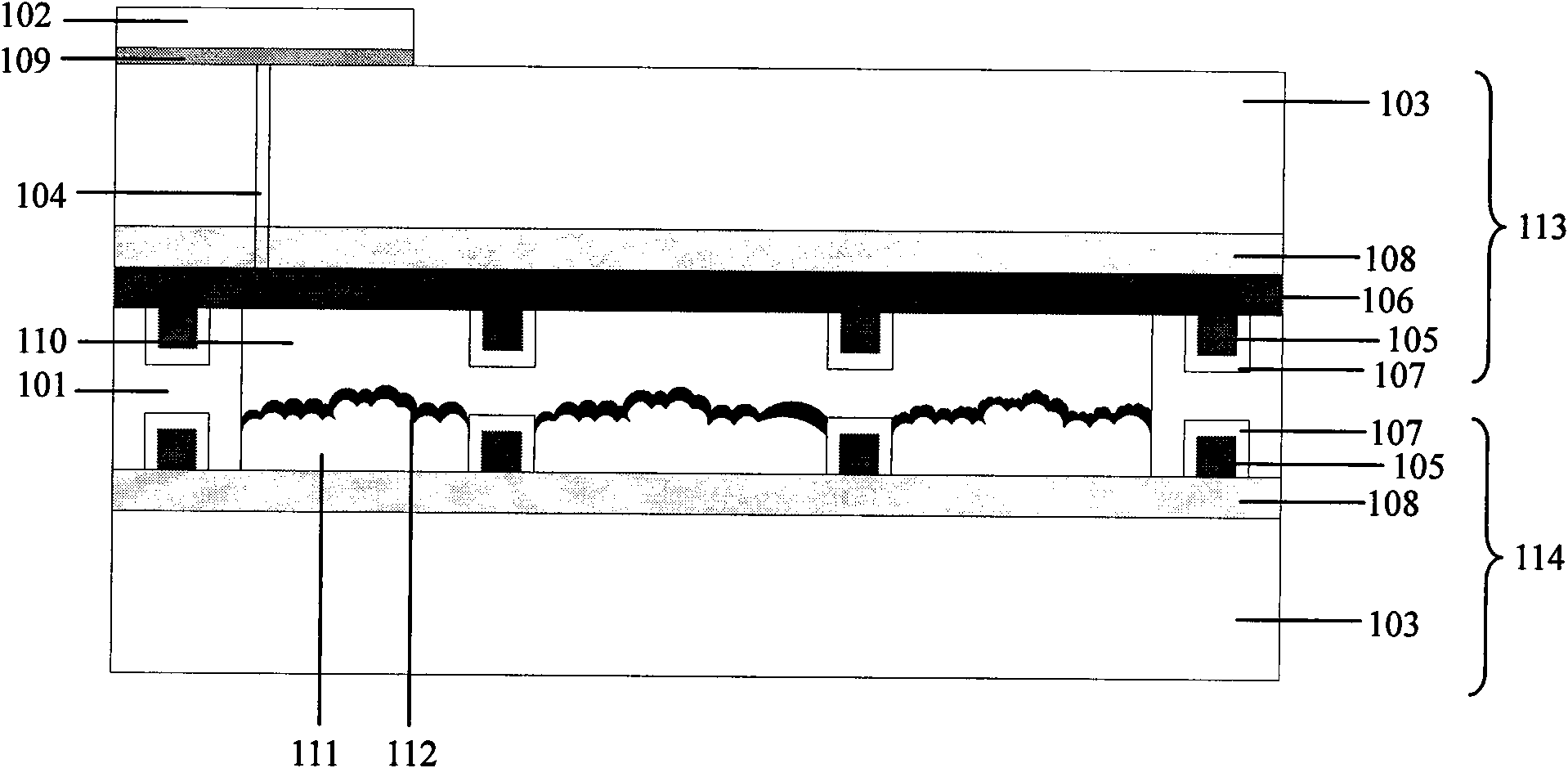

[0046] 1) Preparation of photoanode:

[0047] A transparent conductive film 108 is deposited on the transparent glass substrate 103 by a sol-gel or pulsed laser deposition method; the material of the transparent conductive film 108 is tin-doped indium oxide (ITO); or a purchased transparent conductive film deposited with ITO 108 transparent glass substrate 103;

[0048] Using a flat screen printing process, conductive silver paste is coated on the transparent conductive film 108 of the photoanode 114, and then sintered to form a conductive silver grid layer 105; the conductive silver paste is metallic silver powder, glass powder, high A mixed slurry of molecular binder and terpineol, wherein the mass percentage content of metal silver powder is 60%, the mass percentage content of glass powder is 2%, and the mass percentage content of polymer binder and terpineol is 22%. %, the mass ratio of polymer binder and terpineol is 1:9, and the polymer binder is ethyl cellulose;

[0049] Us...

Embodiment 2

[0062] 1) Preparation of photoanode:

[0063] Depositing a transparent conductive film 108 on the transparent glass substrate 103 by spray pyrolysis or magnetron sputtering; the material of the transparent conductive film 108 is fluorine-doped tin oxide (FTO);

[0064] Using a flat screen printing process, conductive silver paste is coated on the transparent conductive film 108 of the photoanode 114, and then sintered to form a conductive silver grid layer 105; the conductive silver paste is metallic silver powder, glass powder, high The mixed slurry of molecular binder and terpineol; the mass percentage content of metal silver powder is 70%, the mass percentage content of glass powder is 6%, the mass percentage content of polymer binder and terpineol is 30%, The mass ratio of the polymer adhesive and terpineol is 1:15, and the polymer adhesive is epoxy resin;

[0065] Using a flat screen printing process, the insulating medium paste is coated on the conductive silver grid layer 1...

Embodiment 3

[0078] 1) Preparation of photoanode:

[0079] A transparent conductive film 108 is deposited on the transparent glass substrate 103 by a chemical vapor deposition method; the material of the transparent conductive film 108 is aluminum-doped zinc oxide (ZAO);

[0080] Using a flat screen printing process, conductive silver paste is coated on the transparent conductive film 108 of the photoanode 114, and then sintered to form a conductive silver grid layer 105; the conductive silver paste is metallic silver powder, glass powder, high The mixed slurry of molecular binder and terpineol; the mass percentage content of metal silver powder is 80%, the mass percentage content of glass powder is 8%, the mass percentage content of polymer binder and terpineol is 38%, The mass ratio of the high molecular binder and terpineol is 1:20, and the high molecular binder is a phenolic resin;

[0081] Using a flat screen printing process, the insulating medium paste is coated on the conductive silver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com