Preparation method for amphiphilic segmented copolymer with pH value and temperature sensitivities

A multi-block copolymer and amphiphilic technology, which is applied in the field of preparation of amphiphilic multi-block copolymer P-b-P, can solve the problems of ATRP polymerization development limitation, inapplicability of direct polymerization, low reaction rate, etc. The effects of wide range of monomers, high yield, and high polymerization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

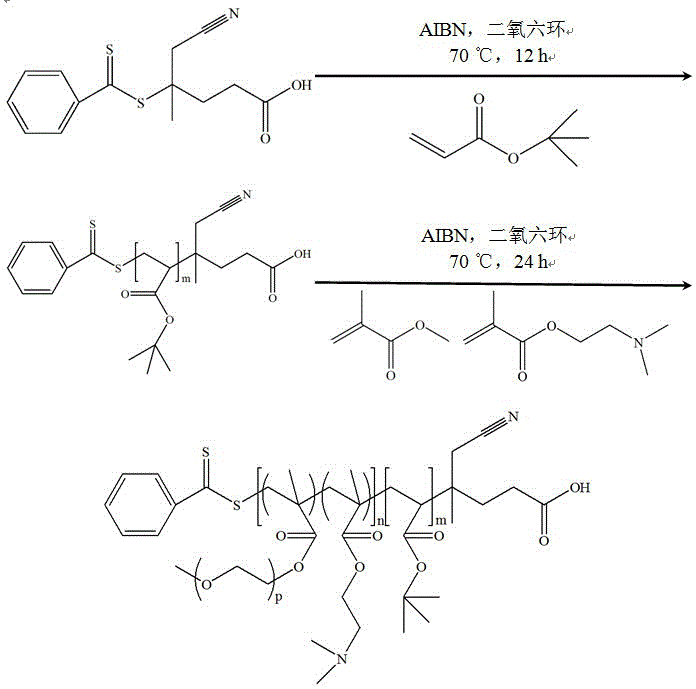

[0022] Step 1: Weigh 2.75 g tert-butyl acrylate (tBA) into a 50 mL single-necked round bottom flask, take 20 mg 4-cyano-4-(thiobenzoyl)valeric acid and 3.52 mg azobis Dissolve isobutyronitrile in a 50 mL beaker by adding 10 mL of dioxane. Then the two were mixed, and the one-necked flask was evacuated at 0 °C through the "T-shaped" tee, and nitrogen gas was introduced. Under the protection of nitrogen, put it in an oil bath at 70°C for 12 h, and stir evenly with magnetic force. After the reaction was completed, the flask was cooled in an ice-water bath and ventilated to the atmosphere, and the cooled solution was added dropwise to 200 mL of methanol / water (v: v = 2: 1) mixed solution, allowed to stand for 4 h, and the upper layer liquid was removed to obtain Pale pink precipitate at the bottom. The above precipitation step was repeated once, and finally the sample was vacuum-dried at 40 °C for 48 h to obtain a pale pink sample, namely poly(tert-butyl acrylate) (P(tBA)).

[...

Embodiment 2

[0028] Compared with Example 1, the amount of tert-butyl acrylate (P(tBA)) in the first step is changed to 2.29 g, and other conditions remain unchanged, then the monomer tert-butyl acrylate, chain transfer agent 4-cyano The molar ratio of base-4-(thiobenzoyl)valeric acid and initiator azobisisobutyronitrile becomes 250: 1: 0.3.

Embodiment 3

[0030] Compared with Example 1, the amount of tert-butyl acrylate (P(tBA)) in the first step is changed to 1.84 g, and other conditions remain unchanged, then the monomer tert-butyl acrylate and chain transfer agent 4-cyanide in the system The molar ratio of base-4-(thiobenzoyl)valeric acid and initiator azobisisobutyronitrile becomes 200: 1: 0.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com