Preparation method of temperature and pH sensitive organic/inorganic hybrid material POSS-PDMAEMA

A hybrid material and sensitive technology, applied in the fields of chemical industry and new materials, can solve the problems of poor product dispersibility, complicated preparation process, low monomer selectivity, etc., and achieve high preparation yield, no environmental pollution, and stereoselectivity. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

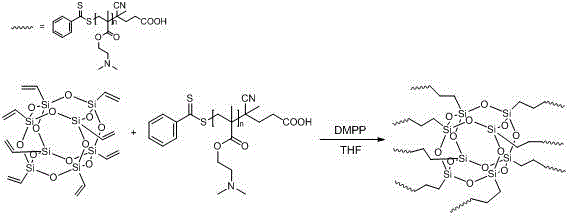

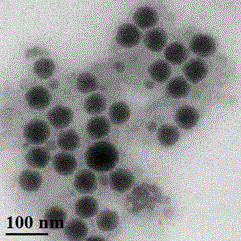

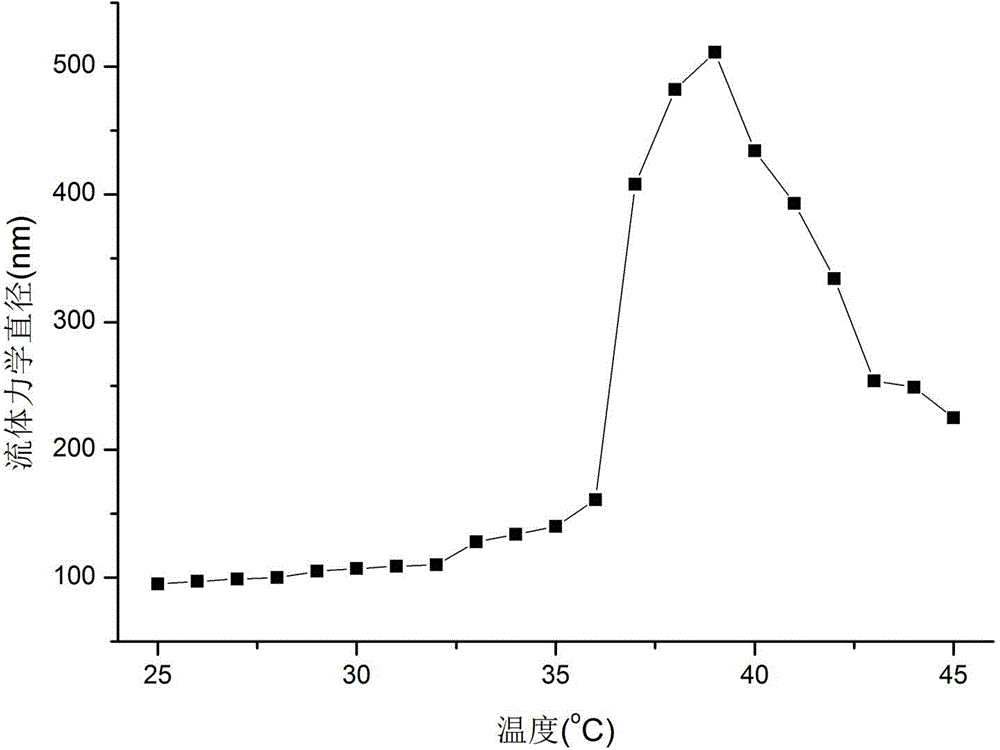

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Take 5.56 g of dimethylaminoethyl methacrylate monomer in a 25 mL single-necked round bottom flask. Take 100 mg of 4-cyano-4-(thiobenzoyl)valeric acid and 20.42 mg of azobisisobutyronitrile powder in a 50 mL beaker, add 10 mL of dioxane to dissolve. Then the two were mixed, and the one-necked flask was evacuated at 0°C through the "T-shaped" tee, and nitrogen gas was introduced. Under the protection of nitrogen, it was placed in a 90°C oil bath with magnetic stirring for 12 h. After the reaction was completed, the flask was cooled to room temperature and ventilated to the atmosphere, and the cooled solution was rotated at 45° C. to remove the solvent to obtain a sample. Dissolve the sample in 10 mL of dichloromethane, add it dropwise to 300 mL of ice petroleum ether, let it stand for 4 h, remove the upper liquid, and obtain a viscous sample at the bottom. The above steps were repeated twice, and finally the samples were vacuum-dried at 45 °C for 24 h. An o...

Embodiment 2

[0031] Same as Example 1, but the amount of dimethylaminoethyl methacrylate in the first step of synthesis is changed from 5.56 g to 19.46 g, monomer (dimethylaminoethyl methacrylate) and chain transfer agent (4 -cyano-4-(thiobenzoyl)valeric acid) and initiator (azobisisobutyronitrile) molar ratio was changed to 350:1:0.3.

Embodiment 3

[0033] Same as Example 1, but the amount of dimethylaminoethyl methacrylate in the first step of synthesis is changed from 5.56 g to 11.12 g, monomer (dimethylaminoethyl methacrylate) and chain transfer agent (4 The molar ratio of -cyano-4-(thiobenzoyl)valeric acid) to the initiator (azobisisobutyronitrile) is 200:1:0.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com