Preparation method of MOFs-chitosan nanofiber composite membrane

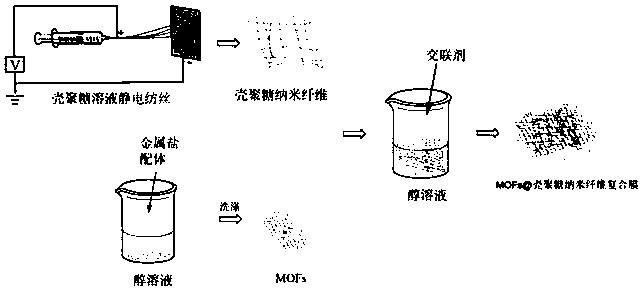

A chitosan nano-fiber composite technology, which is applied in the field of preparation of MOFs-chitosan nanofiber composite membranes, can solve the problems of poor dispersion of MOFs, poor binding fastness between MOFs and chitosan, and easy falling off of MOFs. Excellent water resistance and solvent resistance, high MOFs retention rate, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of ZIF-8-chitosan nanofiber composite film

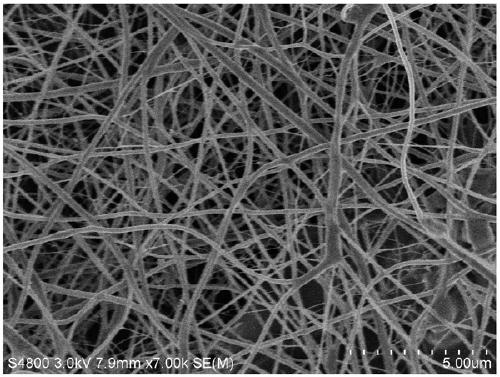

[0034] 1) Preparation of chitosan nanofibers: chitosan and polyethylene oxide are slowly added to glacial acetic acid respectively as the total solution, wherein the final concentration (mass concentration) of glacial acetic acid in the total solution is 3%, and chitosan accounts for 1% of the total solution mass, polyethylene oxide accounts for 0.5% of the total solution mass, turn on the magnetic stirrer, the rotating speed is 500r / min, and the solid is completely dissolved after stirring for 30min; A 5mL syringe was used to extract the solution for electrospinning. Tin foil was used as the receiving plate. The spinning conditions were: positive pressure 2.0KV, negative pressure -5.0KV, injection speed 0.02mm / min, translational speed 100mm / min, The rotating speed of receiving drum is 5r / min; After spinning finishes, tinfoil is taken off, is cut into the fritter of 2cm * 2cm, chitosan fiber is peeled off from tin...

Embodiment 2

[0041] Preparation of ZIF-67-chitosan nanofiber composite membrane

[0042] 1) Preparation of chitosan nanofibers: Chitosan and polyethylene oxide are slowly added to glacial acetic acid respectively as the total solution, wherein the final concentration (mass concentration) of glacial acetic acid in the total solution is 5%, and chitosan accounts for 3% of the total solution mass, polyethylene oxide accounts for 1% of the total solution mass, turn on the magnetic stirrer, the rotating speed is 500r / min, and the solid is completely dissolved after stirring for 30min; A 5mL syringe was used to extract the solution for electrospinning, using tin foil as the receiving plate, the spinning conditions were: positive pressure 13KV, negative pressure -10.0KV, injection speed 0.02mm / min, translational speed 500mm / min, receiving The rotating speed of drum is 30r / min; After spinning finishes, tinfoil is taken off, cut into the fritter of 2cm * 2cm, chitosan fiber is peeled off from tinfo...

Embodiment 3

[0051] Preparation of MIL-101(Cr)-chitosan nanofiber composite film

[0052] 1) Preparation of chitosan nanofibers: chitosan and polyoxyethylene were slowly added to glacial acetic acid respectively as the total solution, wherein the final concentration (mass concentration) of glacial acetic acid in the total solution was 4%, and chitosan accounted for the total 2% of the solution mass, polyethylene oxide accounts for 0.1% of the total solution mass, turn on the magnetic stirrer, the rotation speed is 500r / min, and the solid dissolves completely after stirring for 30min; The syringe extracts the solution for electrospinning, using tin foil as the receiving plate, the spinning conditions are: positive pressure 5.0KV, negative pressure -6.0KV, injection speed 0.05mm / min, translation speed 300mm / min, receiving The rotating speed of drum is 20r / min; After spinning finishes, tinfoil is taken off, cut into the fritter of 2cm * 2cm, chitosan fiber is peeled off from tinfoil;

[0053...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com