Chemical/ionic/physical compounding cross linking hydrogel and preparation method thereof

A technology of cross-linked hydrogel and chemical cross-linking agent is applied in the field of chemical/ionic/physical composite cross-linked hydrogel and its preparation, which can solve the problem of low responsiveness, non-uniformity, single ionic cross-linked gel Physically cross-linked gel comprehensively has poor mechanical properties and other problems, and achieves the effects of mild conditions, short reaction time and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

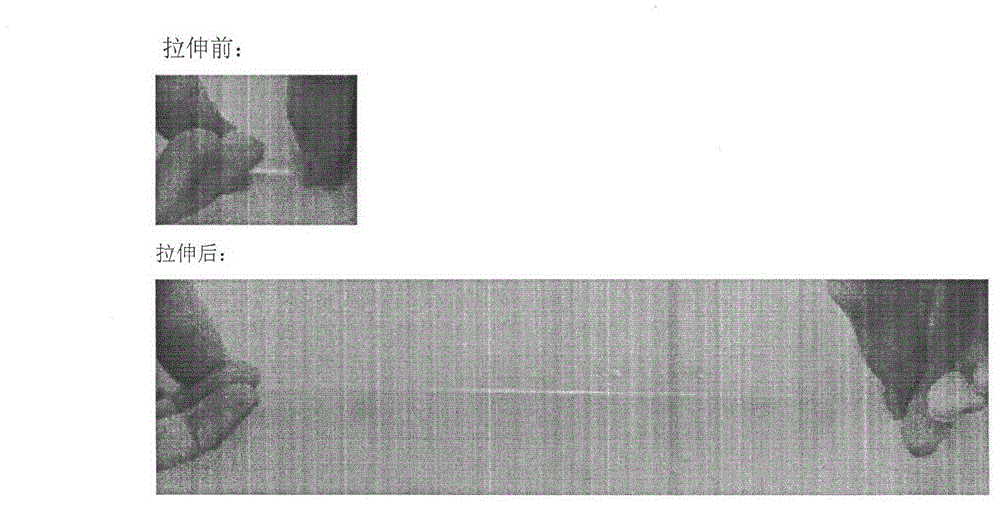

Image

Examples

Embodiment 1

[0036] 1) Preparation of chemical / physical cross-linking gel pre-polymerization solution: add 0.001g hectorite, 1g acrylamide and 0.001g methylenebisacrylamide to deionized water in sequence to prepare an aqueous solution with a mass concentration of 10%. Stir for 20 minutes each time the raw materials are added until a uniform pre-polymerized liquid is formed;

[0037] 2) Preparation of chemical / ionic / physical cross-linking gel pre-polymerization solution: under nitrogen protection and magnetic stirring, slowly add 0.1g of sodium alginate to the pre-polymerization solution in step 1, and add it immediately after no aggregates appear 0.01g calcium sulfate and 0.1% plasticizer glycerin in mass concentration, stirring at low speed for 5min;

[0038] 3) Preparation of chemical / ion / physical composite cross-linked gel: when the gel prepolymerization liquid in step 2 has a viscous appearance, immediately add 0.1g initiator ammonium persulfate, 0.003g catalyst tetramethylethyl ether ...

Embodiment 2

[0042] 1) Preparation of chemical cross-linking gel pre-polymerization solution: Add 2 g of isopropylacrylamide and 0.002 g of methylenebisacrylamide to deionized water in sequence to prepare an aqueous solution with a mass concentration of 9%, and after each addition of raw materials , and stirred for 25 minutes until a uniform pre-polymerized solution was formed;

[0043] 2) Preparation of chemical / ion cross-linked gel pre-polymerization solution: under nitrogen protection and magnetic stirring, slowly add 0.1g sodium alginate and 0.05g chitosan to the pre-polymerization solution in step 1 until no aggregates appear After that, immediately add 0.02g calcium sulfate and 0.1% plasticizer glycerin with a mass concentration, and stir at a low speed for 7 minutes;

[0044] 3) Preparation of chemical / ionic composite cross-linked gel: when the gel prepolymerization solution in step 2 has a viscous appearance, immediately add 0.2g initiator potassium persulfate, 0.006g catalyst sodi...

Embodiment 3

[0048] 1) Preparation of chemical / physical cross-linking gel pre-polymerization solution: add 0.002g lithium magnesium silicate, 1g methylol acrylamide and 0.01g glutaraldehyde into deionized water in sequence to prepare an aqueous solution with a mass concentration of 11%. , each time the raw materials are added, stir for 20 minutes until a uniform pre-polymerized liquid is formed;

[0049] 2) Preparation of chemical / ionic / physical cross-linking gel pre-polymerization solution: under nitrogen protection and magnetic stirring, slowly add 0.05g sodium alginate and 0.05g polylysine to the pre-polymerization solution in step 1, and wait until no After the agglomerates appear, immediately add 0.005 calcium phosphate and 0.1% plasticizer glycerin, and stir at low speed for 8 minutes;

[0050] 3) Preparation of chemical / ion / physical composite cross-linked gel: when the gel pre-polymerization liquid in step 2 has a viscous appearance, immediately add 0.1g initiator potassium persulfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com