Mesotherm hermetic glass and hermetic method for solid oxide fuel cell

A sealing glass, medium temperature technology, applied in the direction of battery components, circuits, electrical components, etc., can solve the problems that do not involve the thermal stability of the sealing glass, do not consider the thermal stability of the sealing glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Examples 1-11 Preparation of medium temperature sealing glass

[0023] According to the mole percentage of each component of each embodiment listed in Table 1, take a certain amount of analytically pure SiO 2 , B 2 o 3 、BaCO 3 , La 2 o 3 , Y 2 o 3 , ZrO 2 、TiO 2 and ZnO were fully mixed and ground by a planetary ball mill respectively, and then taken out and dried; the powders were respectively placed in a platinum alloy dry pot and placed in a box-type resistance furnace, and the temperature was raised to 1300°C to 1500°C in an air atmosphere, and the temperature was constant for 2 ~4 hours, then take it out at 1100°C and pour it into cold water for rapid cooling to form small pieces of medium-temperature sealing glass clinker; after crushing, pass through a 50-500 mesh standard sieve to make medium-temperature sealing glass powder for use.

[0024] SiO 2

Embodiment 12

[0025] Embodiment 12 Long-term thermal stability test:

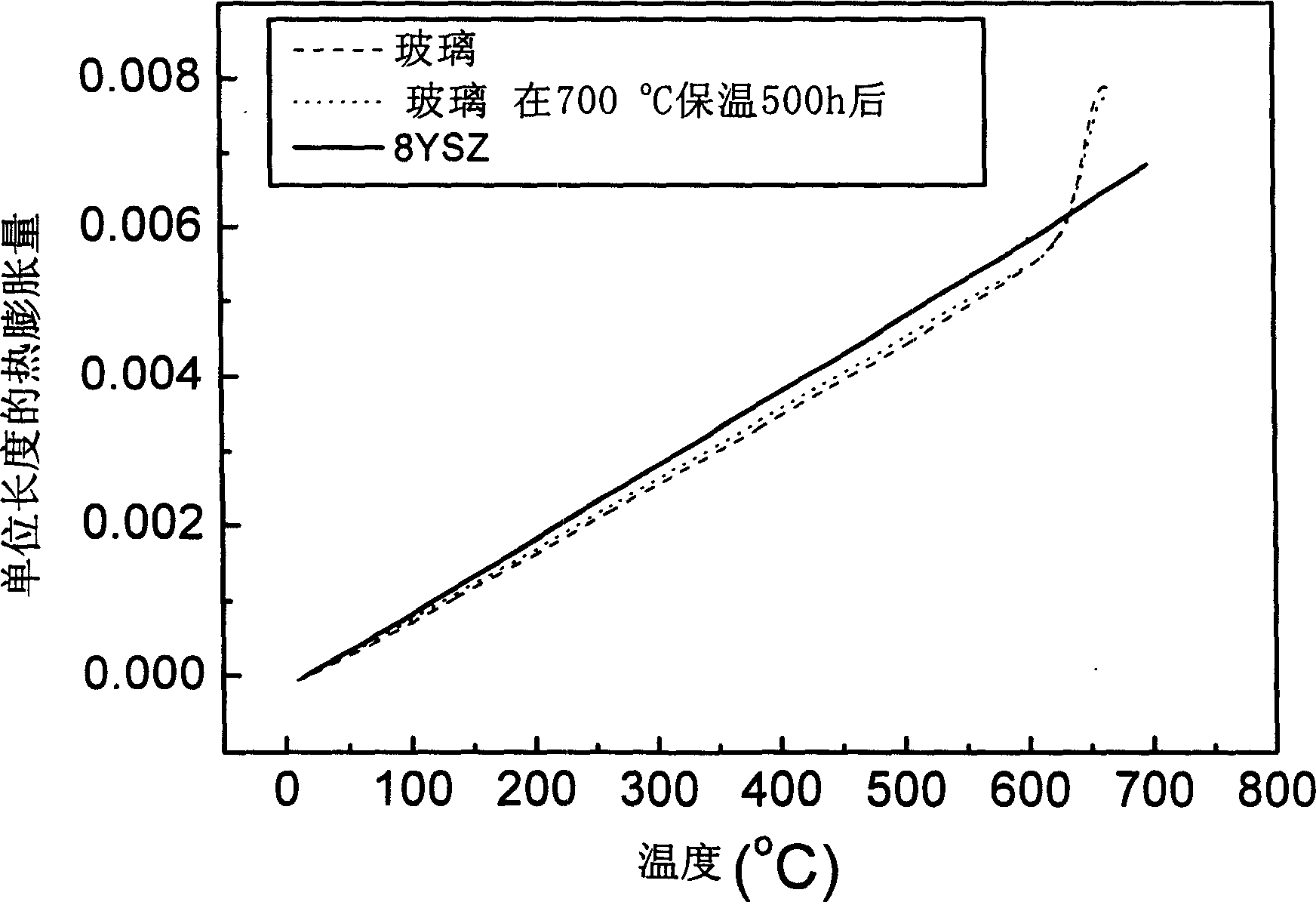

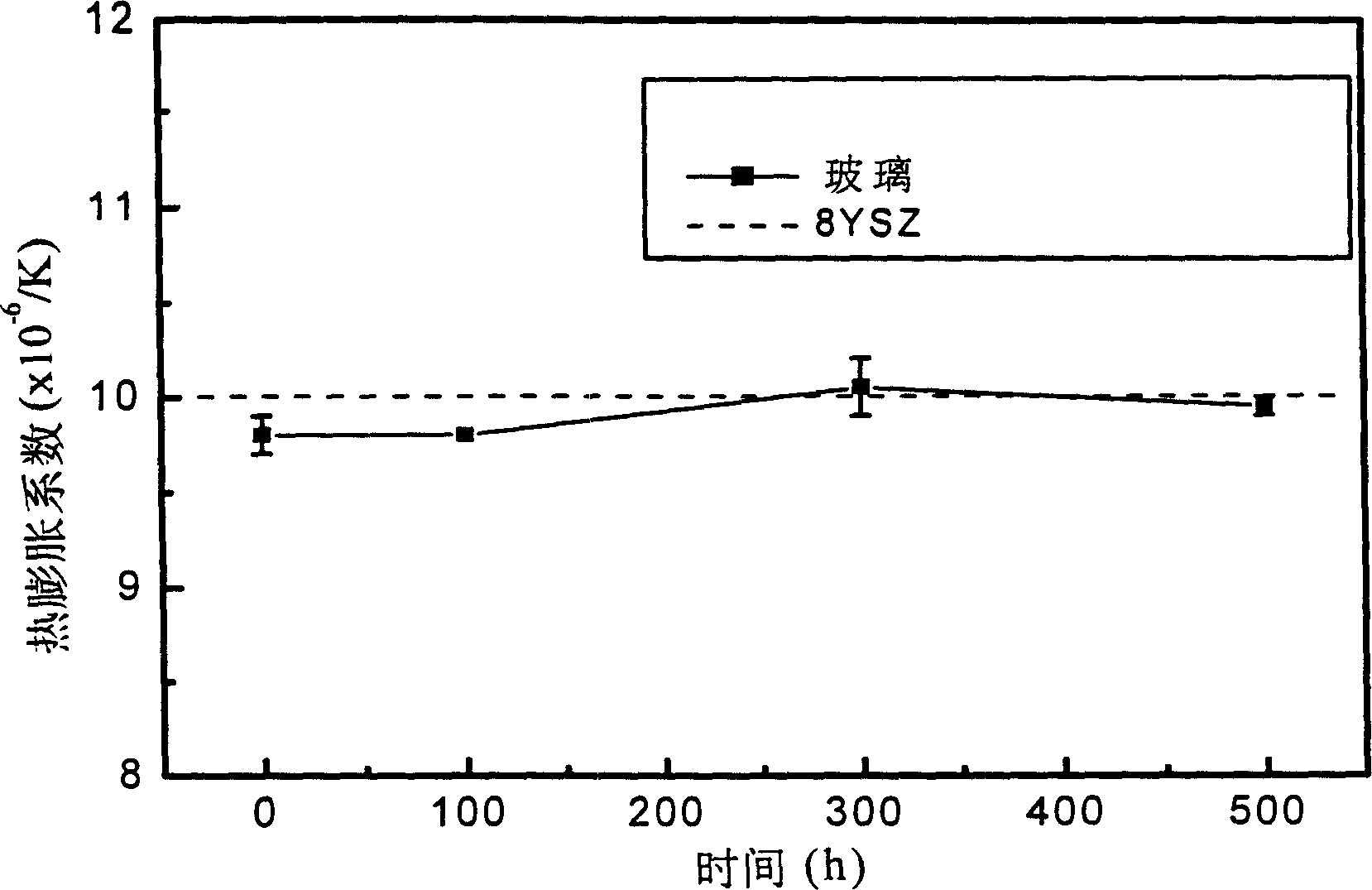

[0026] After the glass is made at 1300°C, the glass in the molten state is lowered to the heat treatment temperature (700°C and 800°C) with the furnace temperature, and kept at the heat treatment temperature for 100h, 300h and 500h respectively to study the thermal expansion coefficient of the glass. Changes in heat treatment time: Cut the glass into a rectangular parallelepiped with a length of 15 mm and a width of 4 mm, and use a high-temperature dilatometer (L75 / 1550, LINSEIS, Germany) to test the thermal expansion coefficient of the glass before and after heat treatment. figure 2 It is a comparison of the unit thermal expansion of a medium-temperature sealing glass prepared in the example before and after heat treatment at 700°C for 500 hours and that of 8YSZ. It can be seen that after 500 hours of heat treatment, the expansion per unit length of the medium-temperature sealing glass does not change significantly. , ...

Embodiment 13

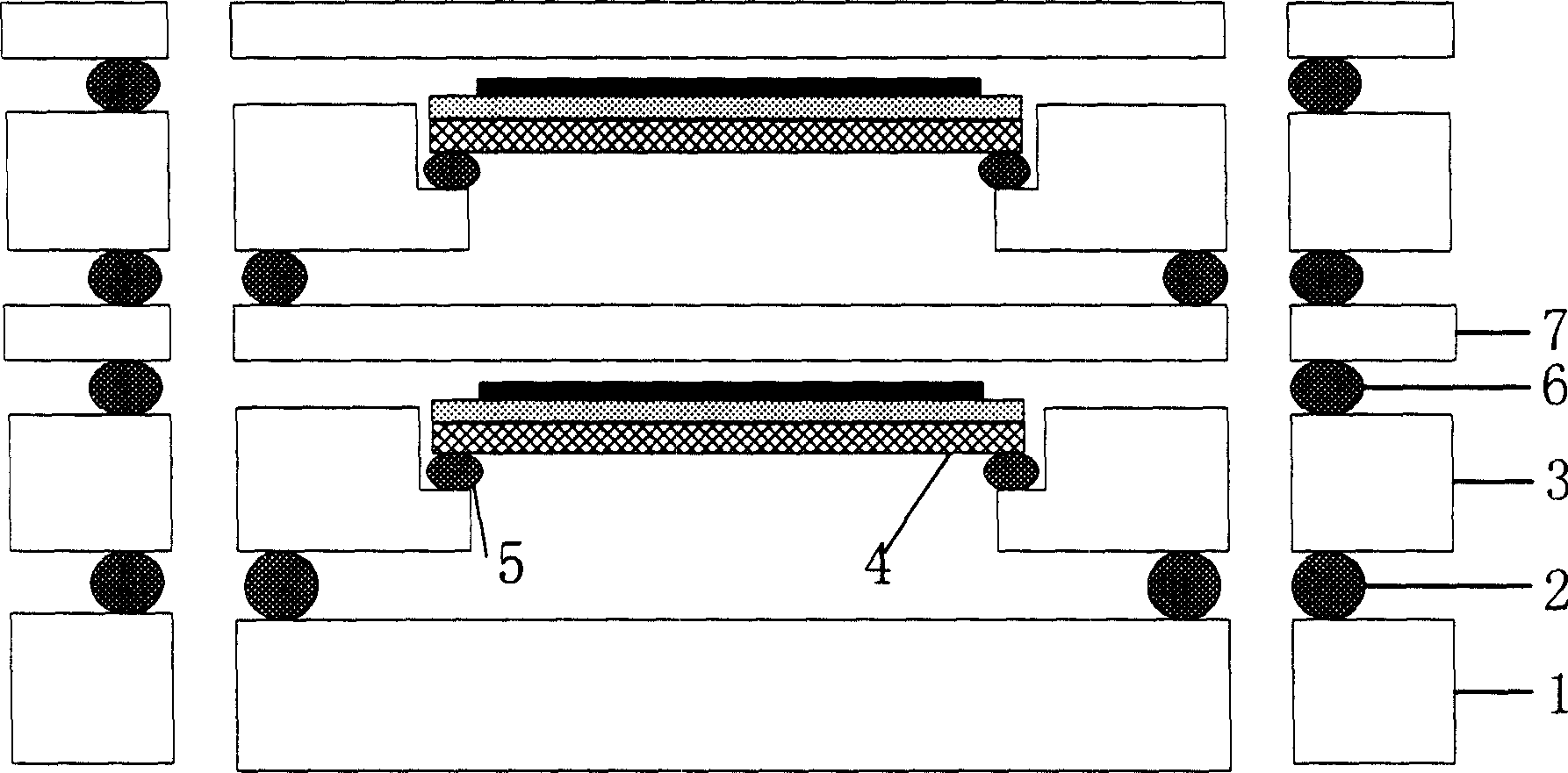

[0027] Embodiment 13 Preparation of sealed body

[0028] Add 30.0 g of the medium-temperature sealing glass frit prepared in Examples 1-11 to a solution consisting of 8.0 g of methacrylamide, 0.8 g of nitrogen-nitrogen dimethylbisacrylamide, 0.8 g of gum arabic, and 15 g of distilled water to form a slurry material; put the slurry in a ball mill to fully grind it, add 0.1g of ammonium persulfate, then cast the slurry into a custom-made mold, put the mold in a 60°C oven to cure for 30min, and wait for the monomers in the slurry to polymerize Afterwards, the formed sealing glass blank is dried, and the dried blank is cut into a shape required for sealing as shown in FIG. 5 to obtain a sealing blank. See Table 2 for other examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com