One-time sintered chrome green frit dry particles and preparation method thereof

A technology of frit and dry granules, which is applied in the field of one-time chrome-fired green frit dry granules and its preparation, can solve the problems of occupying warehouse storage space, increasing the labor workload of employees, and reducing the qualified rate of products, so as to reduce energy consumption and improve The degree of quality control and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

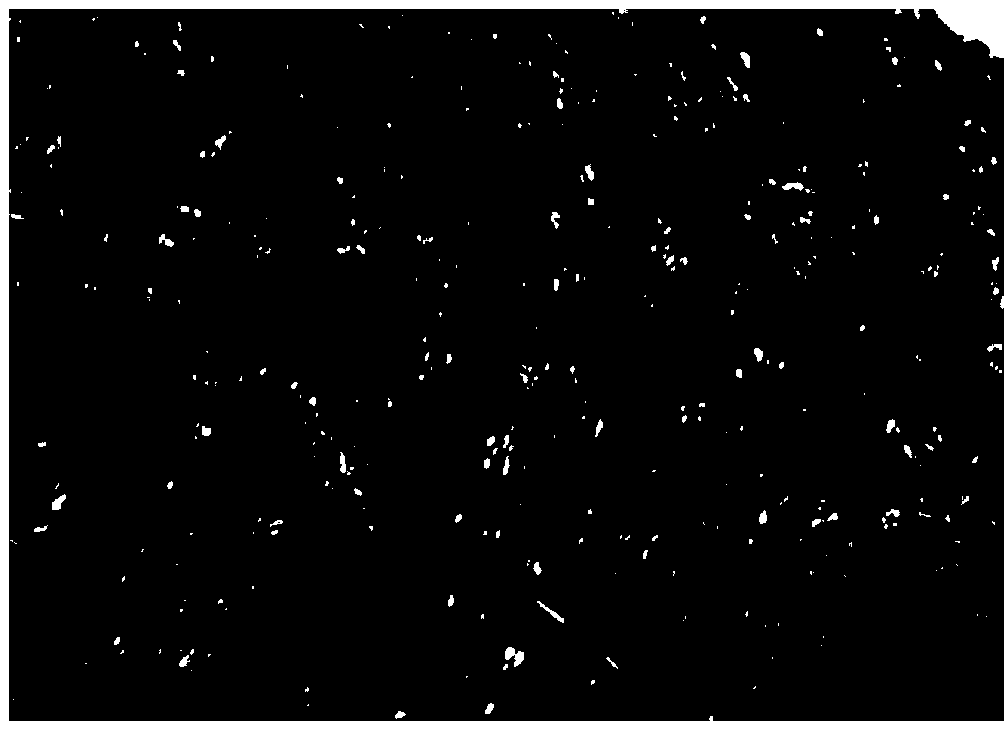

[0031] Weigh 4 parts of boric acid, 3 parts of borax, 10 parts of potassium feldspar, 33 parts of quartz, 25 parts of dolomite, 4 parts of barium carbonate, 11 parts of non-calcined alumina, 5 parts of zirconium silicate, 5 parts of fluorite, chromium oxide 0.5 parts, mixed evenly, melted at 1460°C, kept warm for 3 hours, discharged, quenched, dried, and granulated. The fineness of the dry frit granules was controlled at 10-30 meshes, and a dry chromium-fired green frit was obtained. grains, such as figure 1 As shown, the chrome-green frit dry particles have good gloss and are translucent, shining under the light.

Embodiment 2

[0033] Weigh 2 parts of boric acid, 2 parts of borax, 15 parts of potassium feldspar, 33 parts of quartz, 25 parts of dolomite, 2 parts of barium carbonate, 11 parts of non-calcined alumina, 5 parts of zirconium silicate, 3 parts of fluorite, chromium oxide 0.8 parts, mix evenly, melt at 1480°C, keep warm for 2.5 hours, discharge and quench in water, dry, and granulate. The fineness of the dry granules of the frit is controlled at 10-30 meshes, and a dry chrome-fired green frit is obtained. grain.

Embodiment 3

[0035] Weigh 3 parts of boric acid, 4 parts of borax, 8 parts of potassium feldspar, 35 parts of quartz, 28 parts of dolomite, 4 parts of barium carbonate, 7 parts of non-calcined alumina, 5 parts of zirconium silicate, 8 parts of fluorite, chromium oxide 1.0 parts, mix evenly, melt at 1450°C, keep warm for 3 hours, discharge and quench in water, dry, and granulate. The fineness of the dry granules of the frit is controlled to 10-30 meshes, and the dry chromium frit is obtained once. grain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com