Method for clarifying and decoloring float glass

A float glass and decolorization technology, used in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of reducing glass transmittance, high cost of rare earth oxides, and affecting glass quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in more detail by the following examples, but the present invention is not limited to the following examples.

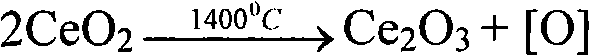

[0075] All use the basic batching of ordinary float glass in the following examples, and the contents of each component are as shown in Table 1:

[0076] Table 1 embodiment basic batching ingredient list / % (by weight percentage)

[0077]

[0078]

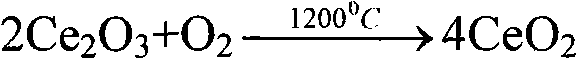

[0079] Introduce the above basic components through sandstone, dolomite, limestone, and soda ash, and add the required La 2 (CO 3 ) 3 、Ce 2 (CO 3 ) 3 、Pr 2 (CO 3 ) 3Or add the rare earth enrichment and Glauber's salt after the initial separation of Baotou rare earth mine, mix the batching materials thoroughly, the total mass is 100g, put them into a corundum crucible, and then put them on the platform in the glass melting furnace. After 5 hours, melt the After the molten glass is cast onto a steel plate coated with zirconium powder, it is placed in a holding fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com