Extreme-pressure anti-wear agent, preparation method of extreme-pressure anti-wear agent and application of extreme-pressure anti-wear agent to water-based metal working fluid

A technology of extreme pressure antiwear agent and processing fluid, which is applied in additives, petroleum industry, organic chemistry, etc. It can solve the problems of environmental protection, poor cooling performance, and poor versatility, and achieve great application prospects and good wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

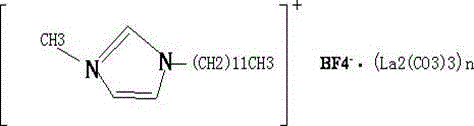

[0041] Synthesis of extreme pressure antiwear agent 1-methyl-3-dodecylimidazolium borate-modified lanthanum carbonate complex: a. Dissolve 60g of lanthanum chloride in distilled water and stir until clear liquid; b. Add dropwise an ethanol solution containing 30g of 1-propyl-3-dodecylimidazolium tetrafluorophosphoric acid and 31.8g of sodium carbonate under stirring, the solution immediately becomes white and turbid, and reacts at constant temperature for 2 hours, and the reaction is complete; c. Chemical, filtered, and precipitated with distilled water for several times, and then washed several times with absolute ethanol; d. Finally, washed several times with potassium tetrafluoroborate aqueous solution for particle exchange, dried to obtain samples, and finely ground for later use. The structural formula of the synthetic polar antiwear agent is:

[0042]

[0043] , due to the influence of the reaction process, n in the synthetic product is 10~40.

[0044] Add the polar ...

Embodiment 2

[0055] Synthesize the lanthanum carbonate complex modified by the extreme pressure antiwear agent 1-methyl-3-dodecylimidazolium borate, the method is the same as that of Example 1,

[0056] To prepare a water-based metalworking fluid added with the above-mentioned extreme pressure antiwear agent, the raw materials are weighed according to the following components by weight:

[0057] Base liquid: 90 parts,

[0058] Oily agent: 19 parts,

[0059] Extreme pressure antiwear agent: 12 parts,

[0060] Anti-rust anti-rust agent: 3 parts,

[0061] Fungicide: 2 parts.

[0062] The base fluid is water: ethylene glycol = 10:1 water-ethanol mixture; the oily agent is water-soluble polyether; the antirust agent is benzotriazole. A water-based metalworking fluid is prepared by a conventional method in the art. The water-based metalworking fluid prepared in Comparative Example 2 does not add the extreme pressure antiwear agent prepared above, and the types and parts of other components ar...

Embodiment 3

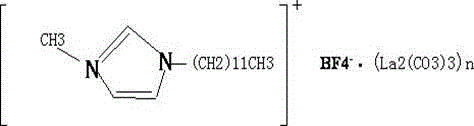

[0068] Synthesis of extreme pressure antiwear agent 1-methyl-3-dodecylimidazolium borate-modified lanthanum carbonate complex: a. Dissolve 60g of lanthanum bromide in distilled water and stir until clear liquid; b. Add drop by drop an ethanol solution containing 60g of 1-propyl-3-dodecylimidazolium tetrafluorophosphoric acid and 31.8g of sodium carbonate under stirring, the solution immediately becomes white and turbid, reacts at constant temperature for 2 hours, and the reaction is complete; c. Chemical, filtered, and precipitated with distilled water for several times, and then washed several times with absolute ethanol; d. Finally, washed several times with potassium tetrafluoroborate aqueous solution for particle exchange, dried to obtain samples, and finely ground for later use. The structural formula of the synthetic polar antiwear agent is:

[0069]

[0070] Due to the influence of the reaction process, the mixture in which n is 10~40 in the synthesized product.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com