Preparation of pure monoclinic phase thorny-sphere-like lanthanum carbonate oxide (La2O2CO3) three-dimensional multi-stage structure

A technology of lanthanum oxycarbonate and spiny spherical shape, which is applied in the field of preparation of three-dimensional multi-level structure of thorny spherical lanthanum oxycarbonate, which can solve the problems of limiting material in-depth research, low stability, and increasing the difficulty of pure crystal phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

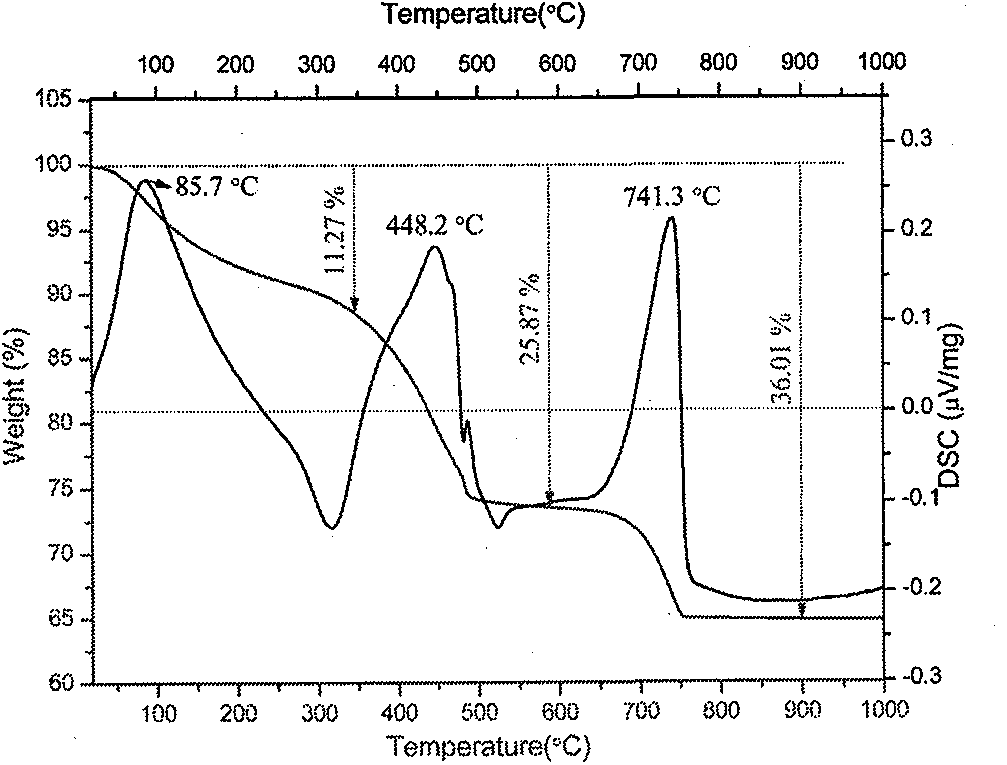

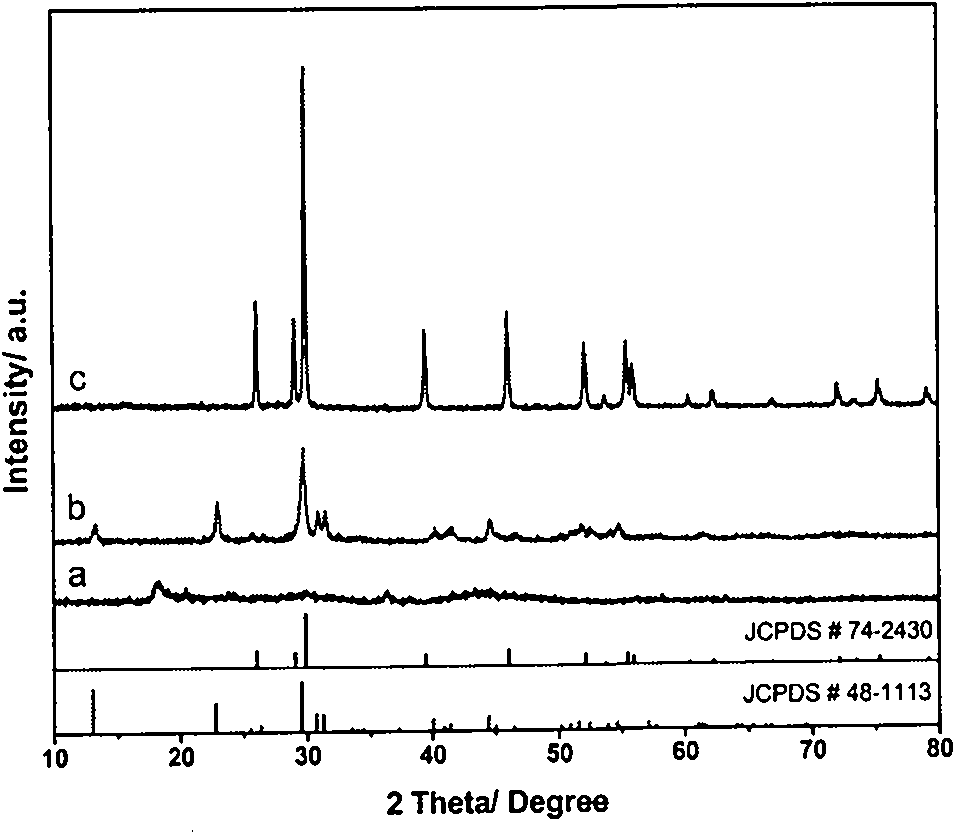

[0017] Example 1: 1% Tb doped-Type Ia-RE 2 o 2 CO 3 preparation of

[0018] First, measure 9.9mL of 0.2M La(NO 3 ) 3 and 0.1 mL of 0.1M Tb(NO 3 ) 3 (Tb 4 o 7 Dissolve in 3M nitric acid solution to prepare) solution, then add 0.2g of EDTA therein, and stir for 5-10min; take 1.5g of urea, dissolve it with 20mL of water to obtain an aqueous solution of urea, and add the aqueous urea solution dropwise to In the above solution; after adjusting the pH value of the reaction solution to 10 with concentrated ammonia water, stir at room temperature for 2 hours; transfer the obtained reaction solution to a 50mL autoclave, and react at 180°C for 2 hours; 3 The OH precursor product was washed several times with water and ethanol, dried at 60°C and recovered for use; the recovered sample was calcined in a tube furnace at 450°C for 3 hours (heating rate 2°C / min) to obtain the final product .

Embodiment 2

[0019] Example 2: 1% Tb doped-La 2 o 3 preparation of

[0020] First, measure 9.9mL of 0.2M La(NO 3 ) 3 and 0.1 mL of 0.1M Tb(NO 3 ) 3 (Tb 4 o 7 Dissolve in 3M nitric acid solution to prepare) solution, then add 0.2g of EDTA therein, and stir for 5-10min; take 1.5g of urea, dissolve it with 20mL of water to obtain an aqueous solution of urea, and add the aqueous urea solution dropwise to In the above solution; after adjusting the pH value of the reaction solution to 10 with concentrated ammonia water, stir at room temperature for 2 hours; transfer the obtained reaction solution to a 50mL autoclave, and react at 180°C for 2 hours; 3 The OH precursor product was washed several times with water and ethanol, dried at 60°C, and recovered for use; the recovered sample was placed in a tube furnace for calcination at 750°C for 3 hours (the heating rate was 2°C / min) to obtain the final product .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com