Method for separating and extracting rare earth and regenerated rare earth polishing powder from waste rare earth polishing powder

A kind of rare earth polishing powder, rare earth technology, applied in the preparation/treatment of rare earth metal compounds, chemical instruments and methods, rare earth metal compounds, etc., can solve the problem of rare earth polishing powder consumption of rare earth, and achieve good polishing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

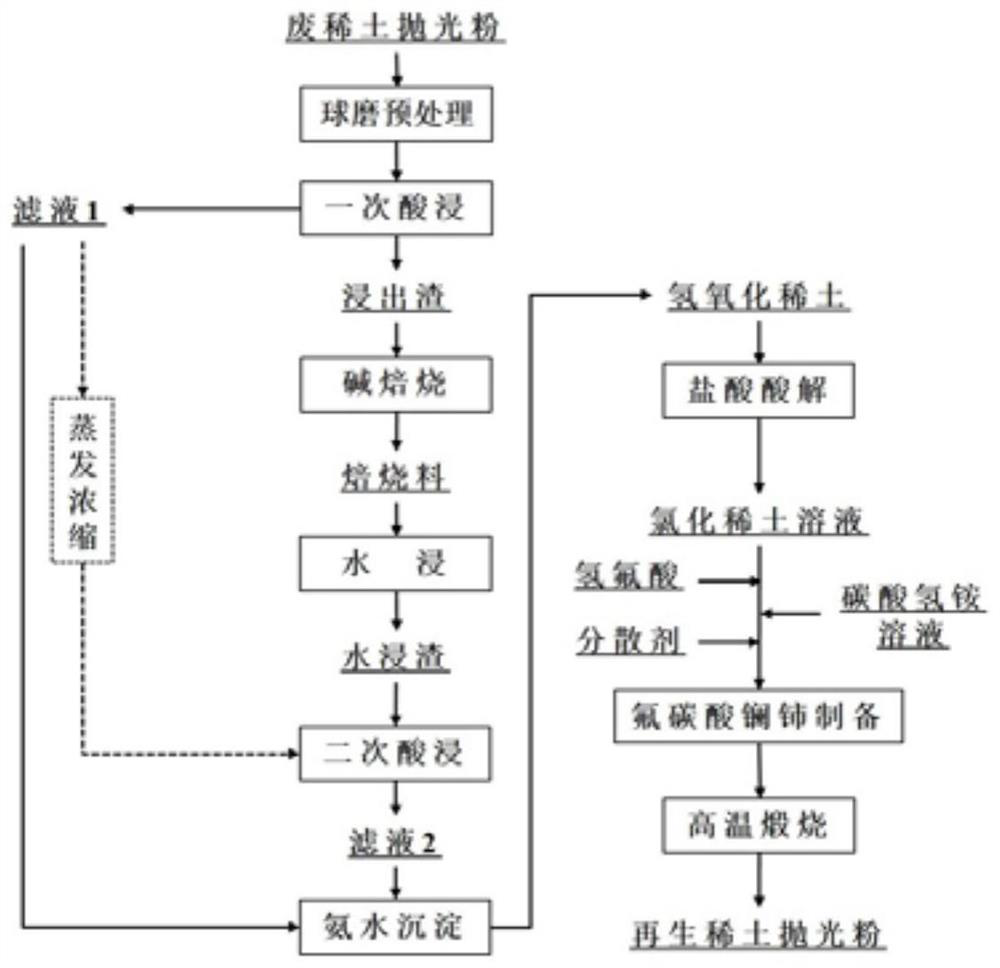

[0023] Proceed as follows:

[0024] (1) Ball milling pretreatment: ball mill waste rare earth polishing powder with a total mass fraction of rare earth oxides of 30% to 200 mesh to obtain ball milling waste;

[0025] (2) One-time acid leaching: put the ball mill waste obtained in step (1) into a container, add hydrochloric acid solution, carry out one acid leaching reaction under heating and stirring, carry out solid-liquid separation after one acid leaching reaction, filter to obtain leaching Slag and filtrate 1; the molar concentration of the hydrochloric acid solution is 6mol / L, the solid-to-liquid ratio of the ball mill waste and the hydrochloric acid solution is 1:7 kg / liter, the leaching temperature is 80°C, the leaching time is 3 hours, and the stirring speed is 500 rpm minute;

[0026] (3) Alkali roasting: mix the leached slag obtained in step (2) with NaOH and roast to obtain a roasted material; the mass ratio of leached slag to alkali is 1:4, the roasting temperatur...

example 2

[0035] Proceed as follows:

[0036] (1) Ball milling pretreatment: ball mill waste rare earth polishing powder with a total mass fraction of rare earth oxides of 40% to 400 mesh to obtain ball milling waste;

[0037] (2) One-time acid leaching: put the ball mill waste obtained in step (1) into a container, add hydrochloric acid solution, carry out one acid leaching reaction under heating and stirring, carry out solid-liquid separation after one acid leaching reaction, filter to obtain leaching Slag and filtrate 1; the molar concentration of the hydrochloric acid solution is 5mol / L, the solid-to-liquid ratio of the ball mill waste and the hydrochloric acid solution is 1:8 kg / liter, the leaching temperature is 70°C, the leaching time is 3 hours, and the stirring speed is 600 rpm minute;

[0038] (3) Alkali roasting: mix the leached slag obtained in step (2) with KOH and roast to obtain a roasted material; the mass ratio of leached slag to alkali is 1:1, the roasting temperature...

example 3

[0047] Proceed as follows:

[0048] (1) Ball milling pretreatment: ball mill waste cerium-based rare earth polishing powder with a total mass fraction of rare earth oxides of 50% to 400 mesh to obtain ball milling waste;

[0049] (2) One-time acid leaching: put the ball mill waste obtained in step (1) into a container, add hydrochloric acid solution, carry out one acid leaching reaction under heating and stirring, carry out solid-liquid separation after one acid leaching reaction, filter to obtain leaching Slag and filtrate 1; the molar concentration of the hydrochloric acid solution is 8mol / L, the solid-to-liquid ratio of the ball mill waste and the hydrochloric acid solution is 1:4 kg / liter, the leaching temperature is 75°C, the leaching time is 1 hour, and the stirring rate is 600 rpm / minute;

[0050] (3) Alkali roasting: mix the leached slag obtained in step (2) with NaOH and roast to obtain a roasted material; the mass ratio of leached slag to alkali is 1:3, the roastin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar concentration | aaaaa | aaaaa |

| Molar concentration | aaaaa | aaaaa |

| Molar concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com