Glue fiber acid bath low temperature evaporation and continuous crystallization process and device thereof

A low-temperature evaporation and viscose fiber technology, which is applied in the fields of fiber chemical characteristics, sustainable manufacturing/processing, and climate sustainability, can solve the problems of underutilized heat energy, large power consumption, and many device tanks, etc., to achieve Stable evaporation and continuous crystallization, few public works projects, compact and reliable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

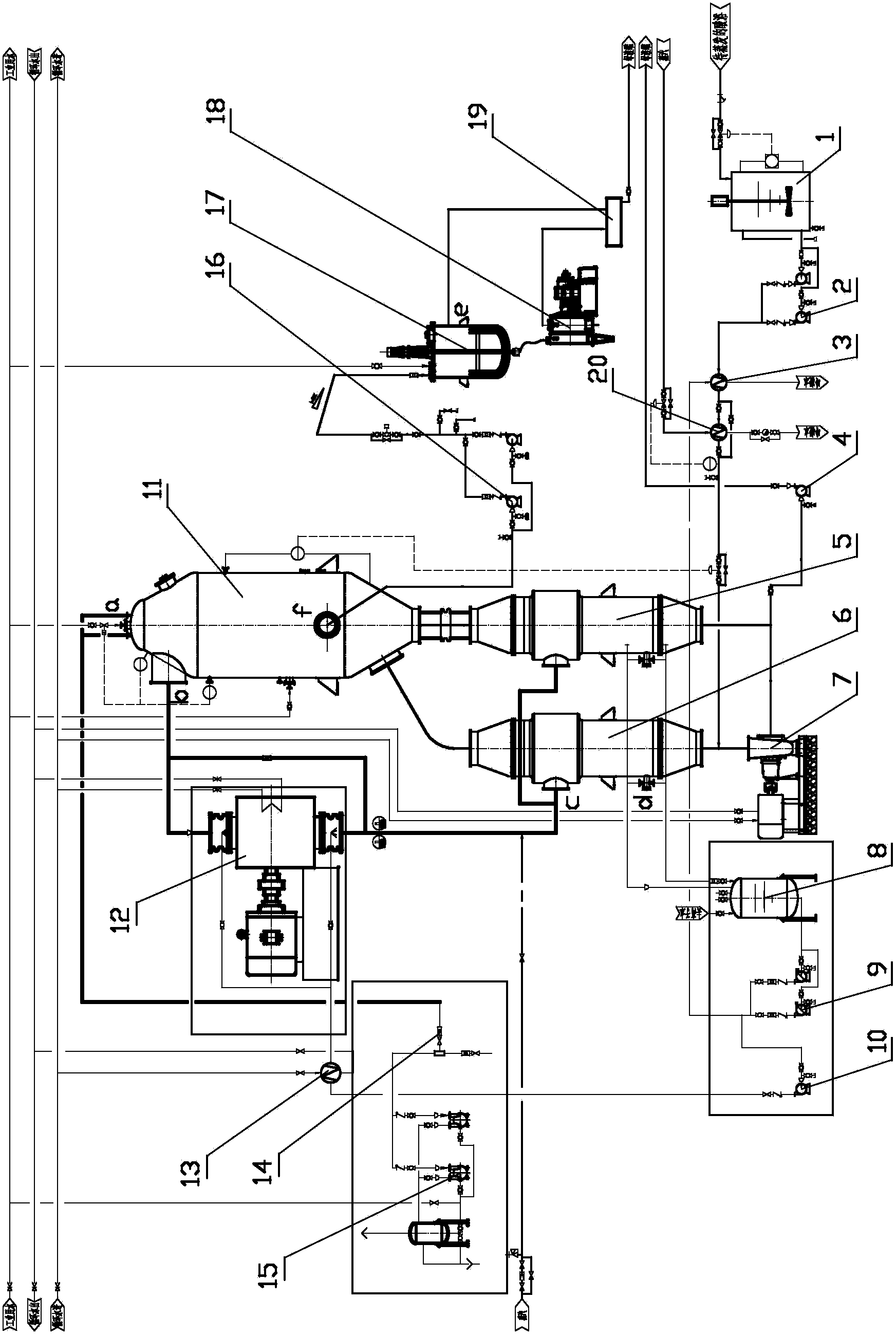

[0018] Viscose fiber acid bath low temperature evaporation and continuous crystallization process, such as figure 1 As shown, the feeding pump 2 sends the acid liquid to be evaporated and crystallized in the acid bath intermediate barrel 1 to the A heat exchanger 6 through the steam preheater 20, and then enters the evaporation crystallizer 11. The boiling point evaporates, and the evaporated steam enters the steam compressor 12 and is compressed into a high-enthalpy steam-water mixture. The steam-water mixture enters the A heat exchanger 6 and the B heat exchanger 5, and the acid bath is heated through the jacket of the heat exchanger. The bath is heated and evaporated between A heat exchanger 6 --- evaporation crystallizer 11 --- B heat exchanger 5 through the circulation pump 7, and the evaporated steam enters the steam compressor 12 again for compression, and the compressed steam and water are mixed The body condenses into water in the jacket of the heat exchanger and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com