New energy-saving technology for producing edible potassium chloride

A technology of potassium chloride and potassium chloride solution, which is applied in the chemical industry, application, food preparation, etc., can solve the problems of large carbon dioxide emissions, high production costs, and high costs, and achieve system stability, fewer operators, and land occupation small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

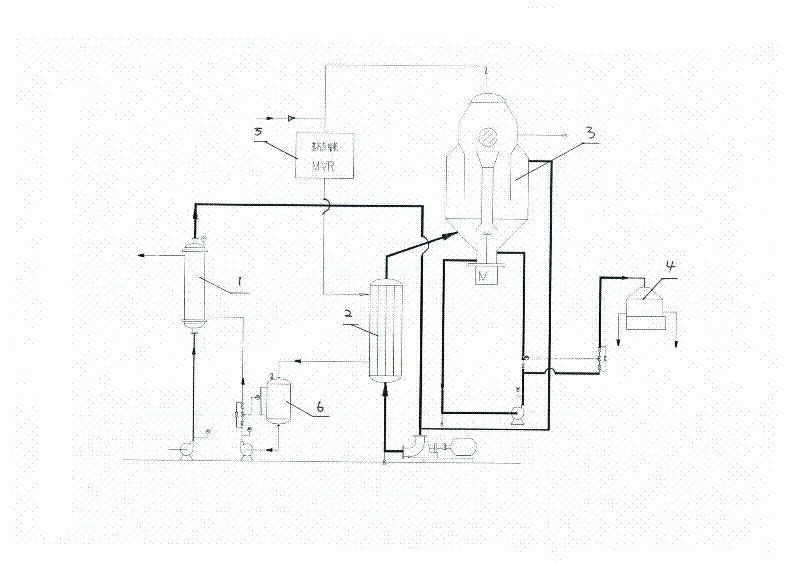

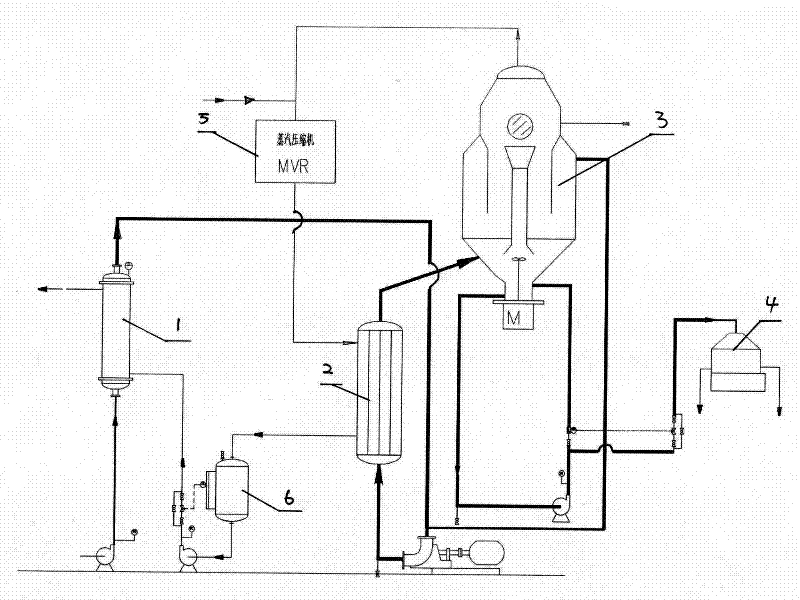

[0010] A new energy-saving process for producing edible potassium chloride, the specific implementation process is as follows:

[0011] Material heating and evaporation: the potassium chloride solution after dissolving and removing impurities is measured by the feed flow meter through the feed pump and then enters the preheater 1 for preheating. The heater 1 preheats the potassium chloride solution to above 80°C, then enters the inlet of the forced circulation pump and mixes with the mother liquor overflowing from the DTB crystallizer, and is transported by the forced circulation pump to enter the heating evaporator 2, and the material passes through the heating evaporator 2 Indirect heating of the shell-side steam, after absorbing the heat, the temperature rises to about 108°C, and then enters the DTB crystallizer 3. Due to the negative pressure in the DTB crystallizer 3, the material evaporates instantly after entering, and most of the water becomes 90°C The secondary steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com