Flotation column process for separating carbon residue in fly ash

A flotation column, fly ash technology, applied in flotation, solid separation and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

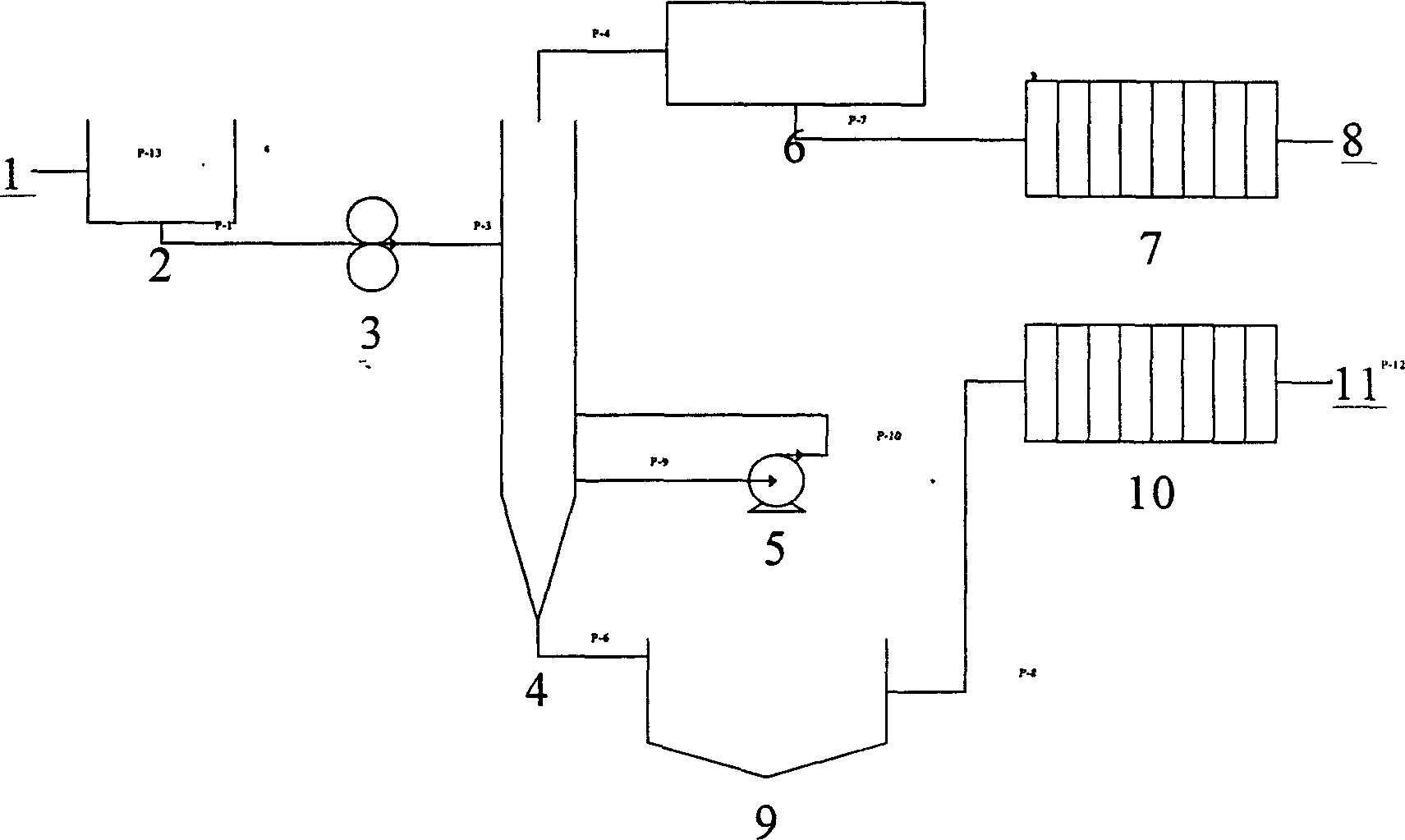

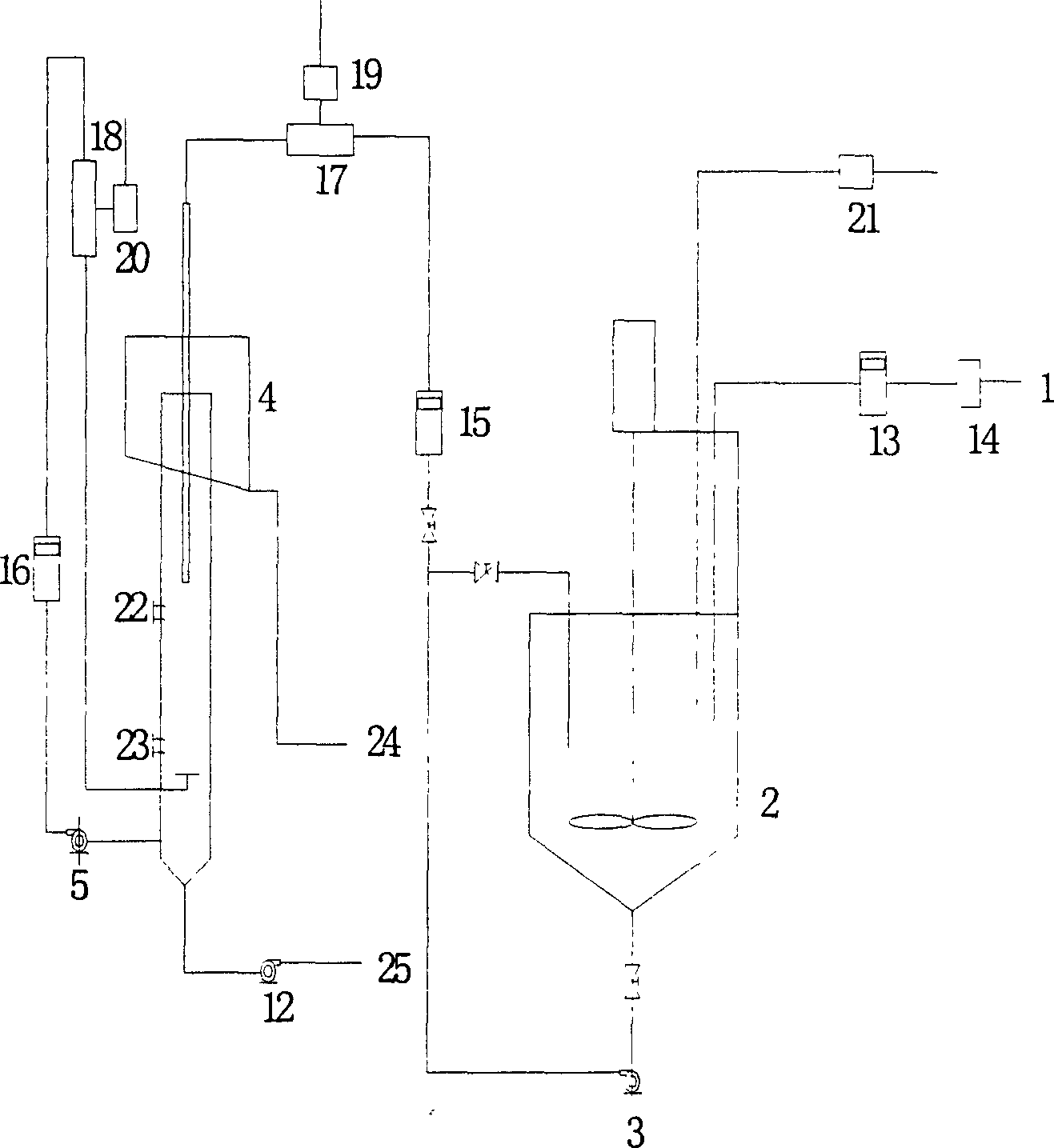

[0023] Here, the present invention is further illustrated by examples. The fly ash of a certain coal-fired power plant in Shanxi is selected, which is characterized by a high loss on ignition index (18%-20%), and its chemical composition is shown in Table 1. Attached figure 2 The process flow shown is for flotation separation.

[0024] Table 1 The chemical composition and ignition loss of the fly ash used

[0025] SiO 2 (%) Al 2 o 3 (%) CaO (%) Fe 2 o 3 (%) MgO (%) SO 3 (%) LOI

[0026] 56.24 28.70 2.08 3.89 0.79 0.23 16.98

[0027] slurry preparation

[0028]To prepare materials in the slurry mixing tank, first add a given amount of clear water, and then turn on the power of the agitator for stirring. During this process, add the pre-measured feed fly ash, and the feed concentrations are 2.75, 5.43, 7.67 and 12.79wt. .%. Stir for 5 minutes first, then add collector (light diesel oil) during the stirring process, continue stirring for 5 minutes, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com