Mechanized production technique for mature vinegar by solid-state acetic acid fermentation

A technology of solid-state acetic acid fermentation and production technology, which is applied in the direction of microorganisms, vinegar preparation, and methods based on microorganisms. It can solve problems such as high labor intensity, damage to fermentation tanks, and single strain structure, so as to increase the content of non-volatile acid. Reduces irritation and enhances enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

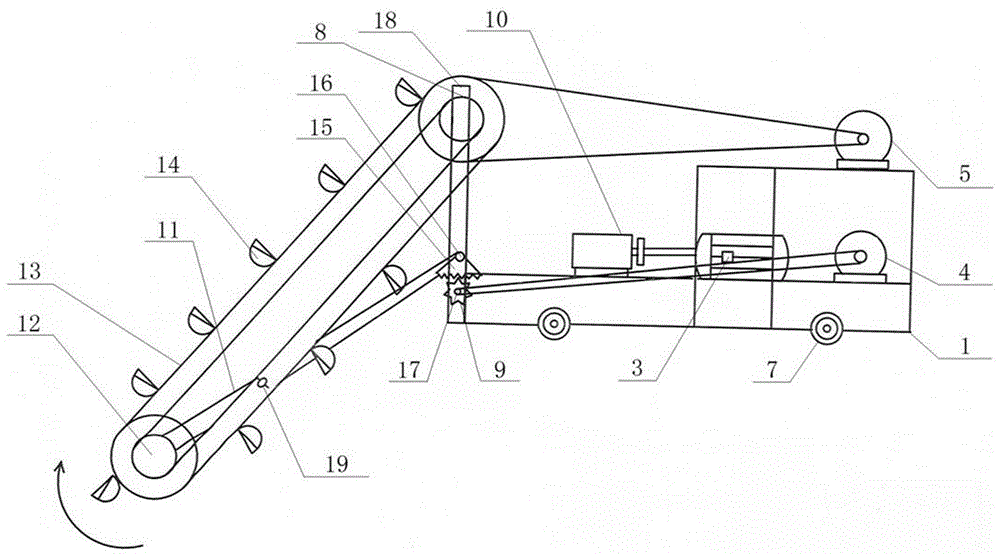

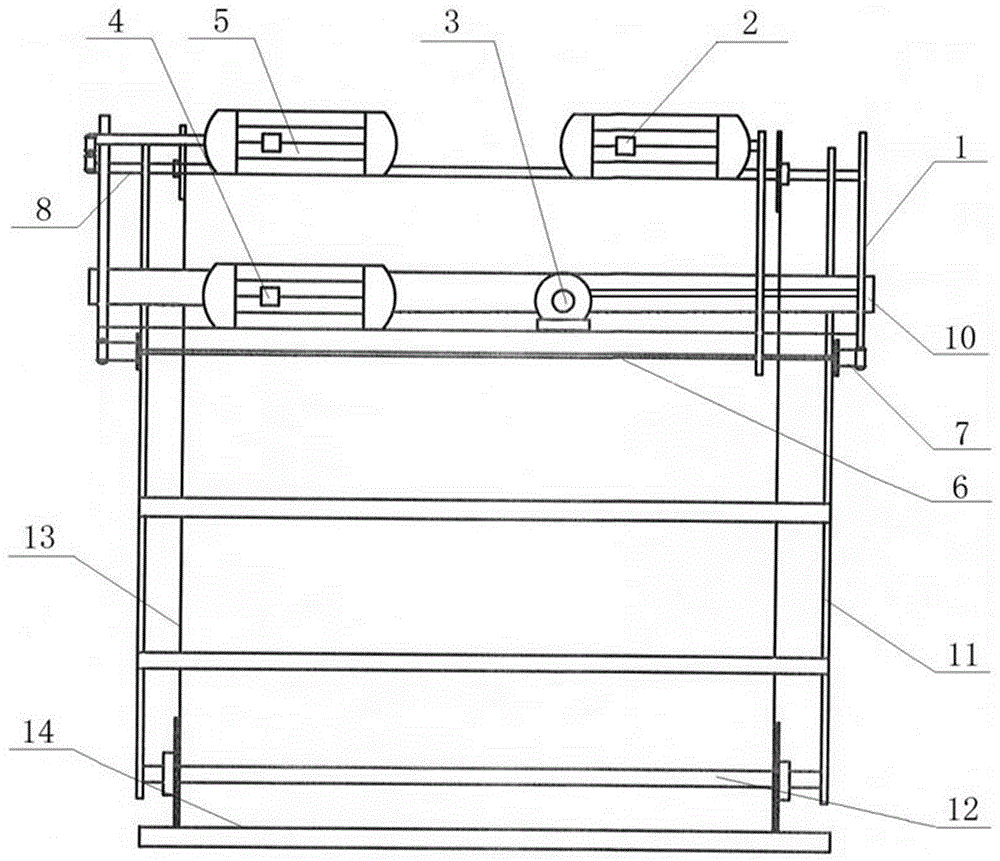

[0043] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

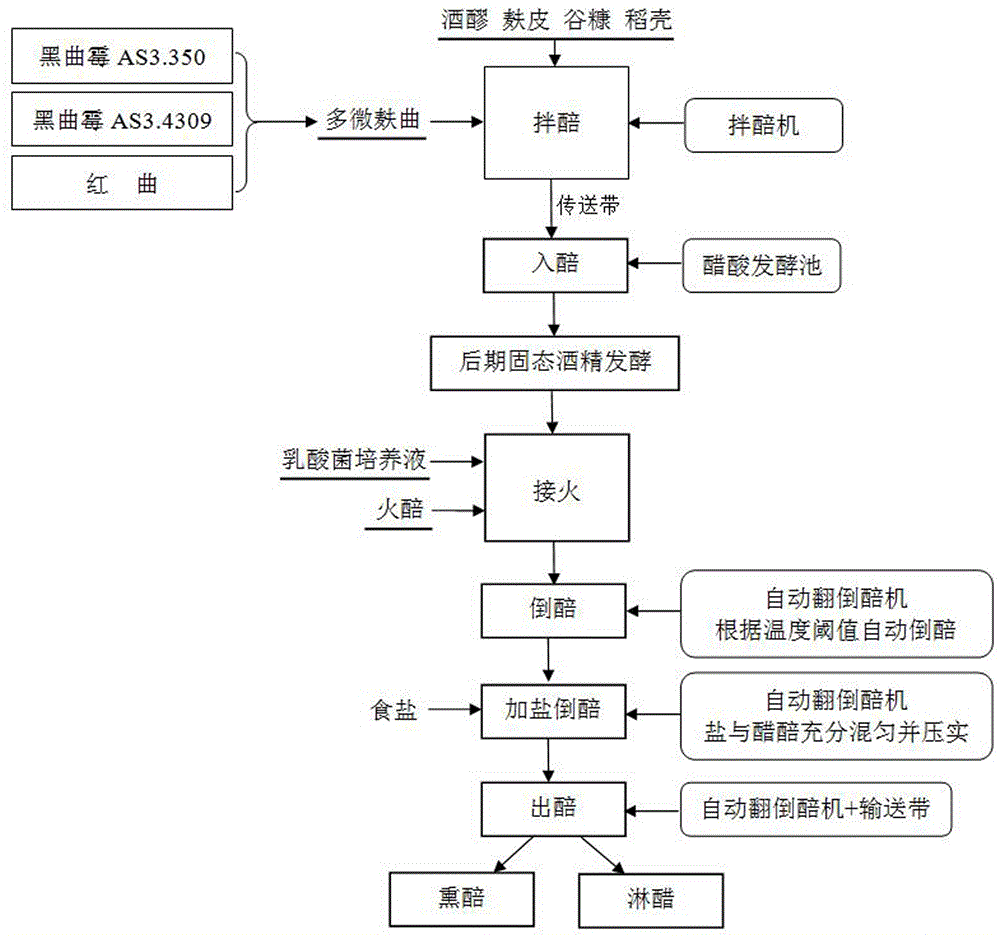

[0044] A mechanized solid-state acetic acid fermentation production process for aged vinegar includes the following steps:

[0045] (1) Preparation of multi-micro-bran koji and lactic acid bacteria liquid

[0046] (1) Preparation of No. I Aspergillus niger Bran Koji

[0047] 1.1. Preparation of No. 1 Aspergillus niger seed koji: use soybean meal and bran mass ratio of 5:1~10:1 as raw materials, add 80%~85% water, mix well, and dispense into 500mL triangles that have been sterilized at high temperature Bottles, each containing about 30g~50g, stuffed with cotton stopper, wrapped with kraft paper, 0.1MPa, sterilized by moist heat for 30 minutes, cooled to 30~35℃, connected to Aspergillus niger (Aspergillus niger) 3.350 1 ~2 loops, mix well and cultivate in a thermostat at 30~32℃. When the surface of the raw material becomes slightly white after a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com