Process and device for dry distillation of oil shale with low gas content

A technology of oil shale and dry distillation, which is applied in the petroleum industry, special forms of dry distillation, direct heating dry distillation, etc. It can solve the problems of process failure and circulating gas heating, so as to reduce the formation of oil sludge, reduce the oil recovery rate, and ensure normal operation The effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

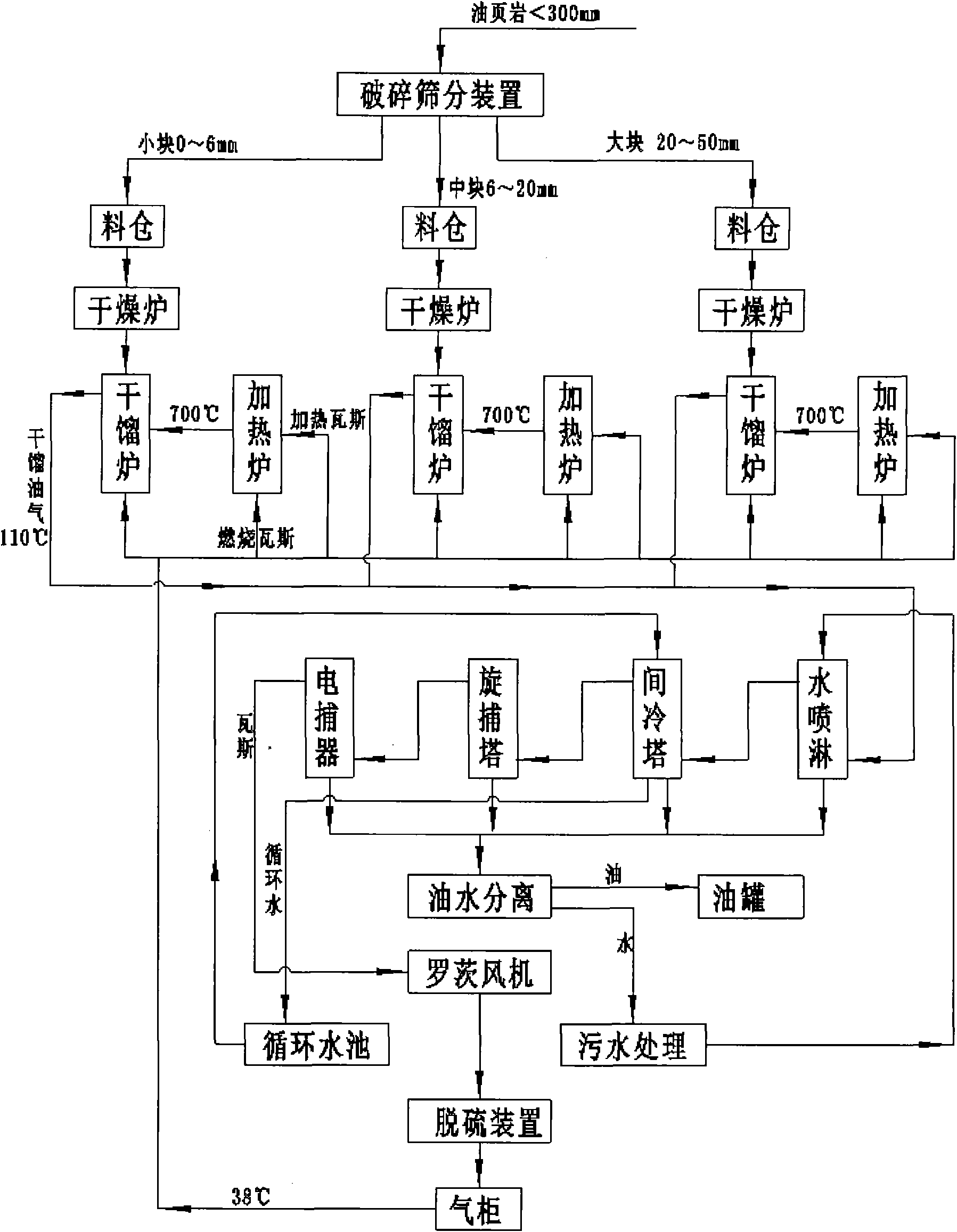

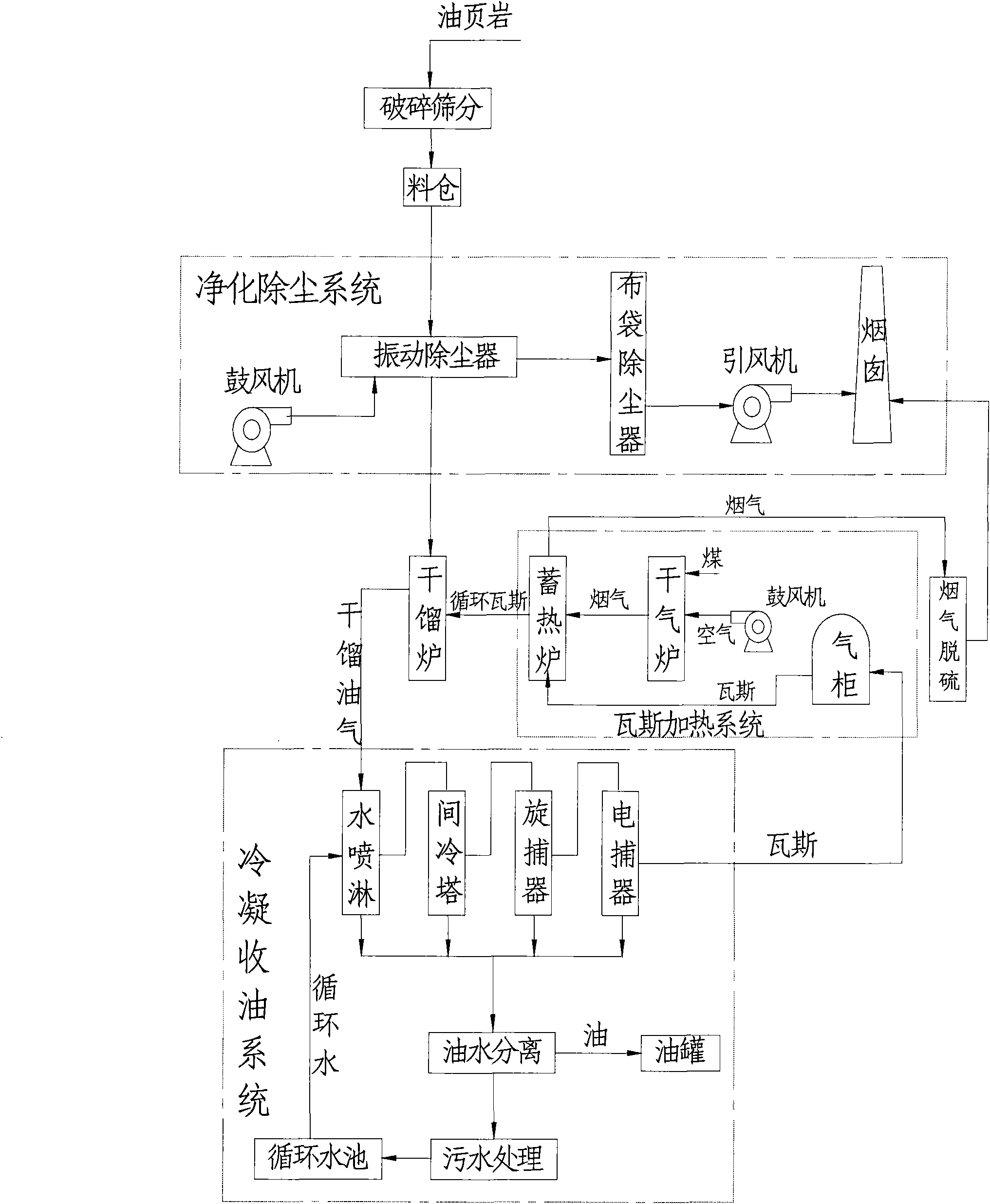

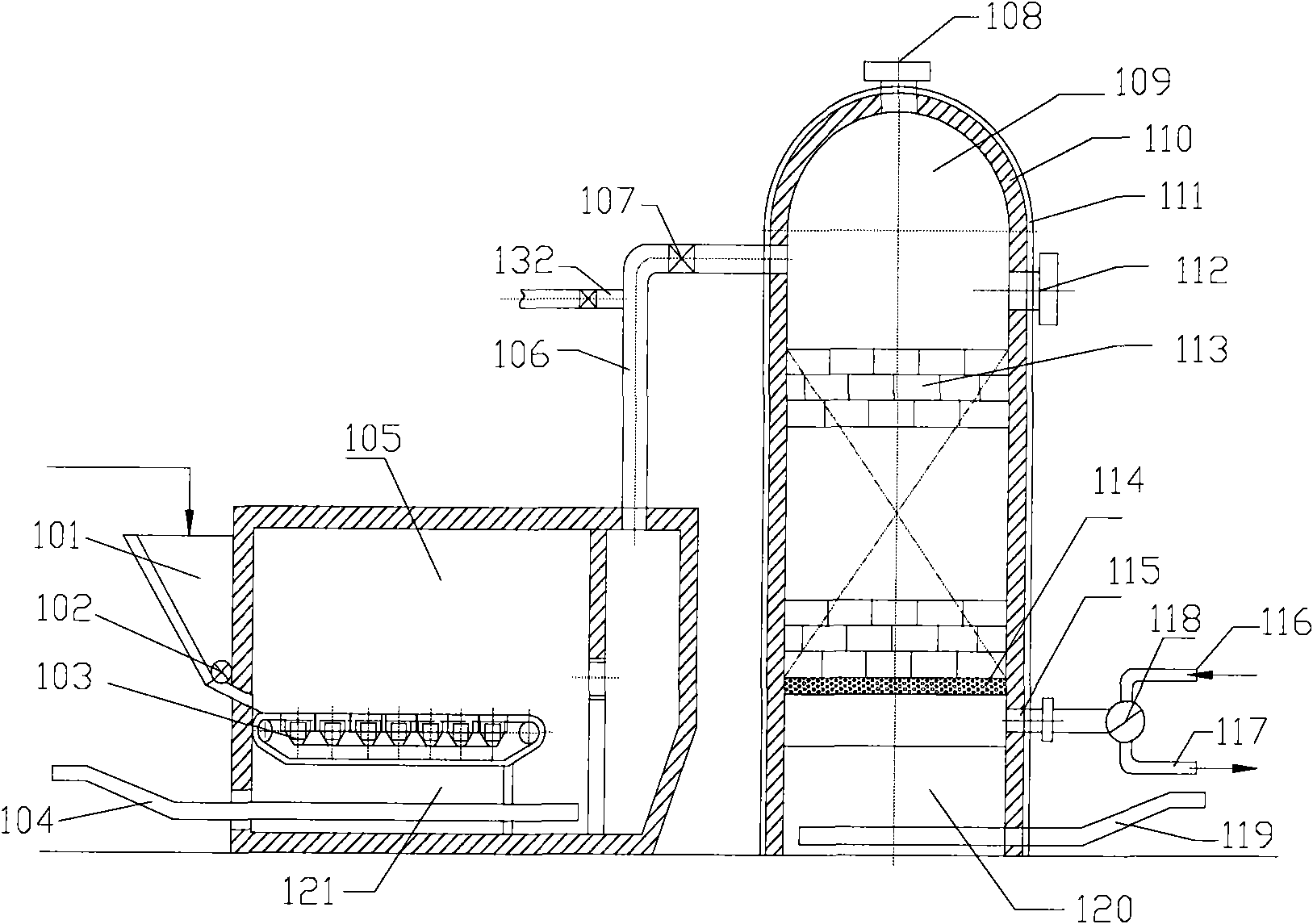

[0040] Process flow of the present invention such as figure 2 As shown in the figure, the flow of this new process is mainly reflected in the figure, which are: ore crushing and screening, classification and storage, purification and dust removal, dry distillation and oil refining, condensation and oil recovery, gas heating, and flue gas desulfurization. The specific process is: crushing and screening the ore into specifications that meet the technical requirements of the retort furnace. Generally, crushing and screening are divided into specifications of 0-6mm, 6-20mm and 20-50mm; the ore conveying system is sent to different silos for storage according to the specifications of the ore; when the retort furnace is working, the oil shale is first sent into the The vibrating dust collector purifies and removes dust. In the vibrating dust collector, the oil shale is added from the upper part, falls onto the vibrating bed, and falls layer by layer. Dust and small particles less...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com