Method for treating odors produced by drying sewage sludge

A sewage sludge and treatment method technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as inapplicable treatment methods, and achieve the effects of large operating flexibility, enhanced safety, and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

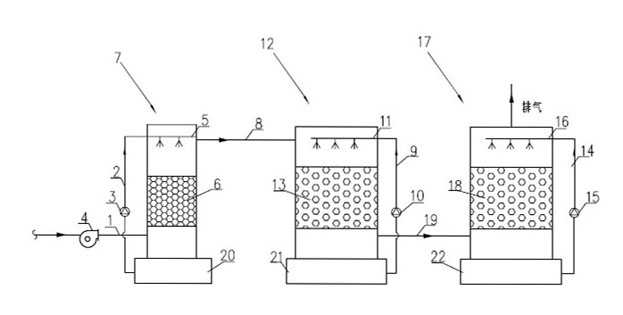

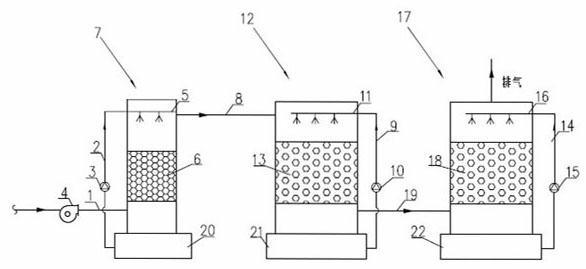

Embodiment 1

[0029] (1) Clear water is filled in the clear water pool 20 in the pretreatment tower 7 . The mixed solution of sodium hydroxide and sodium hypochlorite is contained in the primary reagent pool 21 in the primary spray pool 12, the pH value is 14, and the available chlorine content is 1 g / L. The dilute sulfuric acid solution with a pH of 0 is filled in the secondary chemical pool 22 in the secondary spray pool 17 . The spray water pump 3 is started, and clean water is continuously sprayed at high speed on the surface of the packing material of the packing layer 6 through the circulating water pipe 2 and the spray nozzle 5 to form a clear water liquid film. Start the spray water pump 10, so that the mixed solution of sodium hydroxide and sodium hypochlorite is atomized into small water droplets through the spray nozzle 11 and sprayed on the surface of the packing material of the packing layer 13 to form a liquid film of the mixed solution of sodium hydroxide and sodium hypochlor...

Embodiment 2

[0036] The difference from Example 1 is:

[0037] The mixed solution of sodium bicarbonate and sodium hypochlorite is filled in the primary agent pool 21 of the primary spray pool 12, the pH value is 9, and the available chlorine content is 5g / L. The dilute sulfuric acid solution whose pH is 3 is filled in the secondary chemical pool 22 of the secondary spray pool 17 .

[0038] The superficial flow velocity of the odor through the pretreatment tower and the spray towers at all levels is 3.5m / s.

Embodiment 3

[0040] The difference from Example 1 is:

[0041] The mixed solution of sodium bicarbonate and sodium hypochlorite is filled in the primary agent pool 21 of the primary spray pool 12, the pH value is 10, and the available chlorine content is 3g / L. The dilute sulfuric acid solution with a pH of 2 is filled in the secondary chemical pool 22 of the secondary spray pool 17 .

[0042] The superficial flow velocity of the odor through the pretreatment tower and the spray towers at all levels is 1.5m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com