High-flux polyvinylidene fluoride hollow fiber membrane

A technology of polyvinylidene fluoride and fiber membrane, which is applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of high cost of water treatment, increase water production, reduce manufacturing and use costs, and be flexible The effect of resistance and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

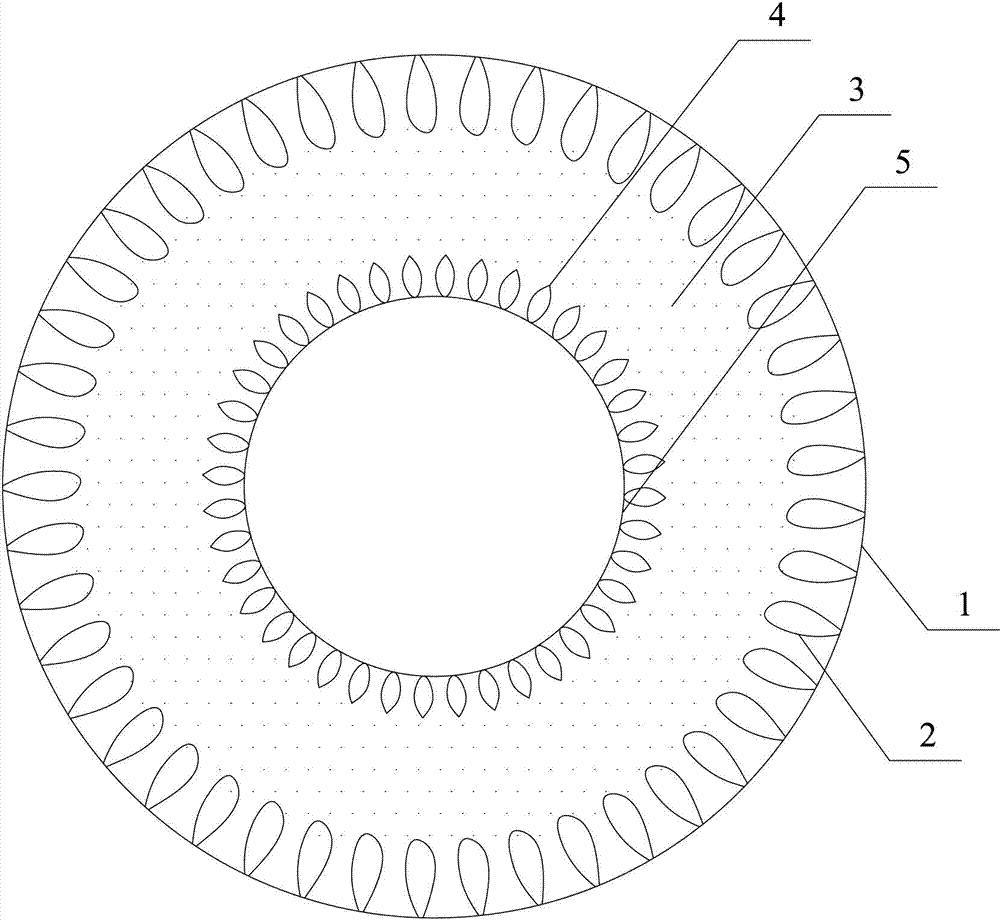

Image

Examples

Embodiment 1

[0038] Embodiment 1: A method for preparing a novel high-throughput polyvinylidene fluoride hollow fiber membrane, comprising the following steps:

[0039] (1) Blend polyvinylidene fluoride with solvent, pore forming agent and non-solvent. Among them, dimethylacetamide and triethyl phosphate are selected as solvents, wherein the ratio of dimethylacetamide and triethyl phosphate is 2:3, and the mass ratio of solvent is 70%; then select: the mass fraction is 12 % polyethylene glycol-200 and polyvinylpyrrolidone, wherein the massfraction of polyethyleneglycol-200 is 10%, and the massfraction of polyvinylpyrrolidone is 2%; massfraction is 1% Tween-80; massfraction 1% propylene glycol; the mass fraction of the blend polymer polyvinylidene fluoride is 16%.

[0040] (2) The above blend was stirred into a uniform solution at 80°C, and then statically defoamed at 60°C for 12 hours, so that the temperature of the casting solution was 60°C.

[0041] (3) The degassed casting solution is...

Embodiment 2

[0043] Embodiment 2: A method for preparing a novel high-flux polyvinylidene fluoride hollow fiber membrane, comprising the following steps:

[0044] (1) Blend polyvinylidene fluoride with solvent, pore forming agent and non-solvent. Among them, dimethylacetamide and triethyl phosphate are selected as solvents, wherein the ratio of dimethylacetamide and triethyl phosphate is 1:4, and the solvent accounts for 68% by mass; then select: the mass fraction is 12 % polyethylene glycol-400; the mass fraction is 1% Span-20; the mass fraction is 1% glycerin; the mass fraction of the blended polymer polyvinylidene fluoride is 18%.

[0045] (2) The above blend was stirred into a uniform solution at 85°C, and then statically degassed at 70°C for 12 hours, so that the temperature of the casting solution was 70°C.

[0046] (3) The degassed casting solution is spun into a hollow fiber membrane by dry-wet spinning. During spinning, the spinning dry length is 20cm, the extrusion speed is 15m...

Embodiment 3

[0048]Embodiment 3: A method for preparing a novel high-throughput polyvinylidene fluoride hollow fiber membrane, comprising the following steps:

[0049] (1) Blend polyvinylidene fluoride with solvent, pore forming agent and non-solvent. Among them, dimethylacetamide and triethyl phosphate are selected as the solvent, wherein the ratio of dimethylacetamide and triethyl phosphate is 1:4, and the solvent accounts for 63% by mass; then select: the mass fraction is 10 % of polyethylene glycol-400; the mass fraction of 2% sodium dodecylbenzene sulfonate; the mass fraction of 1% ethylene glycol; the mass fraction of the blend polymer polyvinylidene fluoride is 24%.

[0050] (2) Stir the above blend at 70°C to form a homogeneous solution, and then statically defoam at 60°C for 12 hours, so that the temperature of the casting solution is 60°C.

[0051] (3) The degassed casting solution is spun into a hollow fiber membrane by dry-wet spinning. During spinning, the spinning dry lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com