Inner-loop three-phase biological fluidized bed type membrane bioreactor (MBR)

A membrane bioreactor and biological fluidized bed technology, applied in the field of internal circulation three-phase biological fluidized bed MBR membrane bioreactor, can solve the problems of easy pollution, limited application space and high energy consumption of MBR membrane bioreactor , to achieve the effects of slowing membrane fouling, prolonging the backwash cycle and prolonging the life of the membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will be further described in conjunction with the accompanying drawings and specific application examples

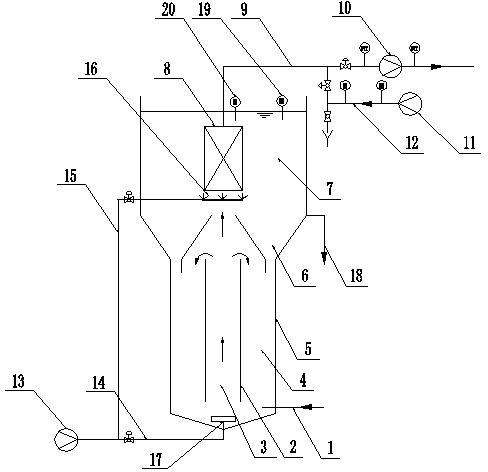

[0038] An internal circulation three-phase biological fluidized bed type MBR membrane bioreactor, which is to put the sedimentation tank at the top of the internal circulation three-phase biological fluidized bed into an MBR membrane module to form an MBR membrane bioreactor. Such as figure 1As shown, the internal circulation three-phase biological fluidized bed MBR membrane bioreactor includes an internal circulation fluidized zone at the bottom and an MBR membrane bioreactor zone at the top. The inner circulation fluidization zone is composed of two concentric cylinders, the inner cylinder and the outer cylinder, the inner cylinder is the upflow zone, and the outer cylinder is the downflow zone; a swirl shear aerator is installed at the bottom, and the inside is filled with activated carbon or three-dimensional hollow packing. An annular sludge ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com