Method of recycling cutting suspension

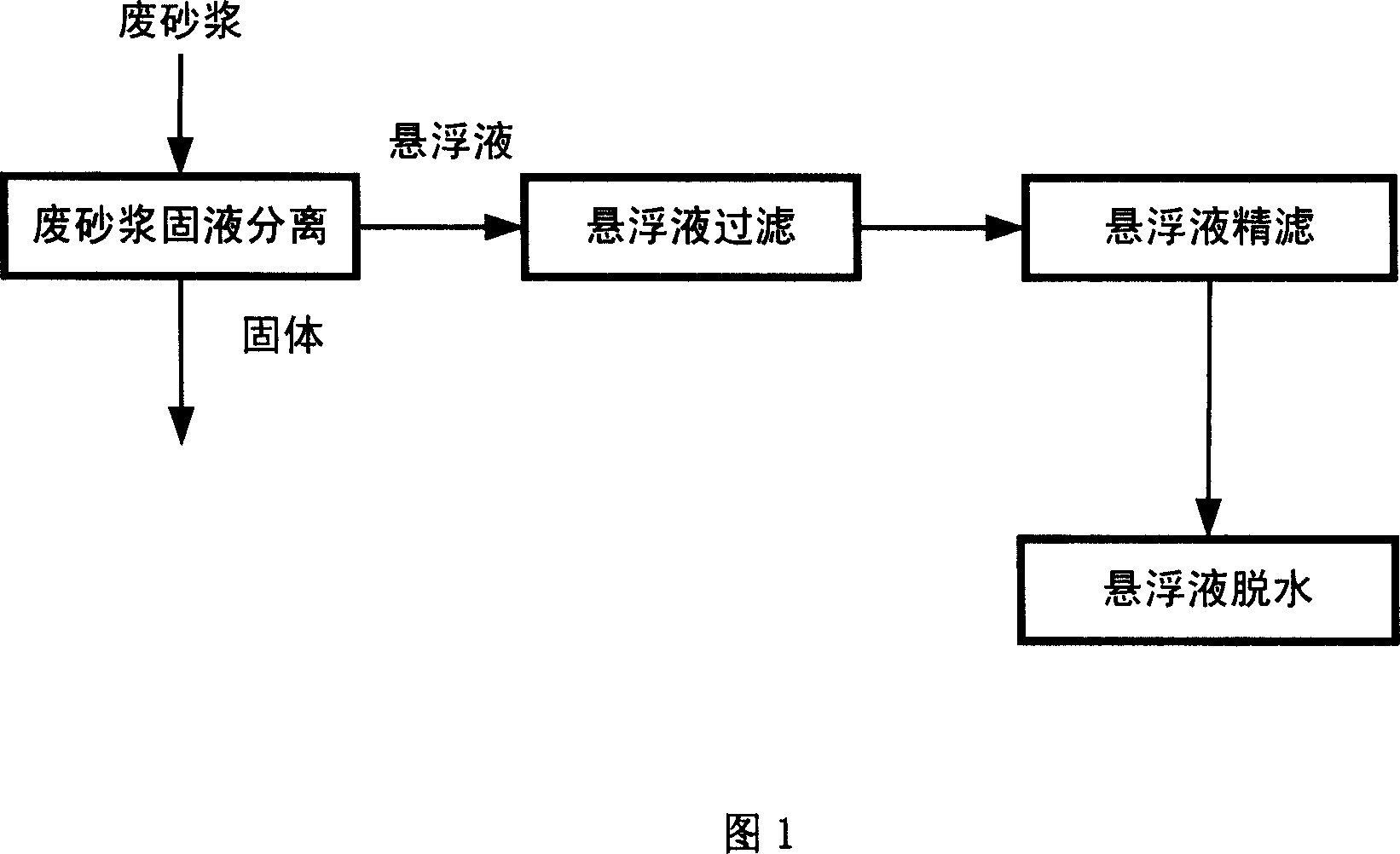

A suspension and solid-liquid separation technology, which is applied to the used abrasive processing device, abrasive, metal processing equipment, etc., can solve the problems that the cutting mortar cannot be recycled, the production efficiency is affected, and the performance of the cutting mortar cannot be used again.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An example of using the present invention to process the cutting mortar prepared by JIS800 type silicon carbide micropowder and PEG300 type suspension in a ratio of 0.95:1 to complete the single crystal slicing process.

[0030] The uniformly stirred waste mortar is filtered out of the liquid suspension through a vacuum filter, and the filtrate is collected. Mix the filtrate with a polyacrylamide aqueous solution with a concentration of 0.1% at a ratio of 1:0.03 and stir evenly. After solid flocs appear in the mixed solution, input it into a disc centrifuge, and adjust the inlet pressure of the disc centrifuge at 0.15Mpa, the separation factor is set to 6500, so that the solid content is less than or equal to 5%, and the filtrate product is collected. Input the collected filtrate into a precision filter equipped with a filter element group of less than 1 μm, adjust the inlet pressure of the filter at 0.3Mpa so that the solid content is ≤0.01%, and collect the filtrate. ...

Embodiment 2

[0032] An example of using the present invention to process the cutting mortar prepared by JIS800 type silicon carbide micropowder and PEG400 type suspension in a ratio of 0.95:1 to complete the single crystal slicing process.

[0033] The uniformly stirred waste mortar is filtered out of the liquid suspension through a vacuum filter, and the filtrate is collected. Mix the filtrate and diatomaceous earth at a ratio of 1:0.3 and stir evenly, then input it into a plate filter to make the solid content ≤ 5%, and collect the filtrate product. Input the collected filtrate into a precision filter equipped with a filter element group of less than 1 μm, adjust the inlet pressure of the filter at 0.2Mpa so that the solid content is ≤0.01%, and collect the filtrate. Put the filtrate into a vacuum drying oven to fully dry and concentrate, the temperature is less than 160°C, take it out after the moisture reaches the specified ≤0.5%, and place it in a dry environment to cool to room tempe...

Embodiment 3

[0035] An example of using the present invention to treat cutting mortar prepared by JIS1200 type silicon carbide micropowder and PEG300 type suspension in a ratio of 0.95:1 to complete the single crystal slicing process.

[0036] The uniformly stirred waste mortar is filtered out of the liquid suspension through a vacuum filter, and the filtrate is collected. Mix the filtrate with a carboxymethylcellulose aqueous solution with a concentration of 3% in a ratio of 1:0.05 and stir evenly. After solid flocs appear in the mixed solution, it is input into a series connection composed of a filter press and a disc centrifuge. For the filter unit, adjust the inlet pressure of the disc centrifuge to 0.1Mpa, set the separation factor to 8000, make the solid content ≤ 5%, and collect the filtrate product. The collected filtrate is input into a precision filtration device equipped with a microfiltration membrane module, and the inlet pressure of the filtration device is adjusted to mainta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com