Battery capacitor membrane filtration material prepared by using wet papermaking forming process, and preparation method thereof

A diaphragm filter and capacitor technology, applied in the field of filter separation and electrochemical, wet papermaking, can solve the problem of uncontrollable pore size, etc., achieve the effect of small size deformation, long service life and good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

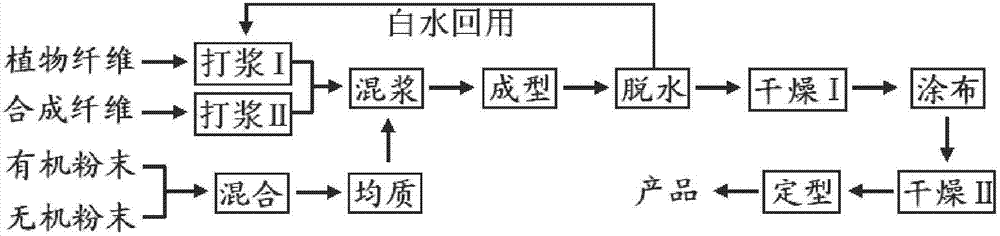

Method used

Image

Examples

Embodiment 1

[0034] (1) 5 kilograms of wood pulp fibers: beat by 2% concentration;

[0035] (2) 95 kilograms of polyvinyl alcohol fibers: beating by 2% concentration;

[0036] (3) 5 kilograms of polyethylene powder, 20 kilograms of activated white clay powder: mix and homogenize by 5% concentration;

[0037] (4) Add plant fiber slurry, synthetic fiber slurry and organic-inorganic powder slurry to a beater or a slurry delivery pipeline, and mix evenly;

[0038] (5) Use a rotary screen former to form on the Internet at a concentration of 0.1%;

[0039] (6) Using a vacuum pump to absorb water and press for dehydration;

[0040] (7) Use a drying cylinder to directly contact once for drying;

[0041] (8) Carry out conventional method coating with the acrylic glue solution of concentration 10%;

[0042] (9) Direct contact with the drying cylinder for secondary drying;

[0043] (10) The finished product of the filter material for the battery capacitor diaphragm is obtained by hot pressing wi...

Embodiment 2

[0045] (1) 8 kilograms of cotton pulp fibers: beating by 1% concentration;

[0046](2) 62 kilograms of polypropylene fibers and 30 kilograms of polyvinyl alcohol fibers: beating at a concentration of 1%;

[0047] (3) 16 kilograms of potassium titanate powder and 4 kilograms of polypropylene powder: mix and homogenize at a concentration of 4%;

[0048] (4) Add plant fiber slurry, synthetic fiber slurry and organic-inorganic powder slurry to a beater or a slurry delivery pipeline, and mix evenly;

[0049] (5) Use inclined wire former to form on the Internet at a concentration of 0.05%;

[0050] (6) Using a vacuum pump to absorb water and press for dehydration;

[0051] (7) Use a drying cylinder to directly contact once for drying;

[0052] (8) Carry out conventional method coating with the polyvinyl alcohol glue solution of concentration 10%;

[0053] (9) Direct contact with the drying cylinder for secondary drying;

[0054] (10) The finished product of the filter material ...

Embodiment 3

[0056] (1) 10 kilograms of wood pulp fibers: beating at a concentration of 1.5%;

[0057] (2) 70 kilograms of polyester fiber and 20 kilograms of polyvinyl alcohol fiber: beating by 1% concentration;

[0058] (3) 10 kg of potassium titanate powder, 10 kg of activated white clay, and 4 kg of polyethylene wax powder: mix and homogenize at a concentration of 6%;

[0059] (4) Add plant fiber slurry, synthetic fiber slurry and organic-inorganic powder slurry to a beater or a slurry delivery pipeline, and mix evenly;

[0060] (5) Use a rotary screen former to form on the Internet at a concentration of 0.06%;

[0061] (6) Using a vacuum pump to absorb water and press for dehydration;

[0062] (7) Use a drying cylinder to directly contact once for drying;

[0063] (8) carry out conventional method coating with the phenolic resin glue solution of concentration 10% and modified starch glue solution;

[0064] (9) Direct contact with the drying cylinder for secondary drying;

[0065]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com