Polyvinylidene fluoride based micro-pore film and preparation method thereof

A technology of polyvinylidene fluoride and microporous membrane, which is applied in the direction of chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of complicated process and insufficient hydrophobicity of microporous membrane, and achieve good air permeability, small pore size, and high filtration efficiency. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of polyvinylidene fluoride-based microporous membrane:

[0032] In the first step, the two polymers of PVDF (Shanghai Sanaifu New Material Co., Ltd., brand FR907) and water-soluble polyester size (produced by Shandong Juye Fine Chemical Co., Ltd.) were mixed at a ratio of 10:1 at 50 Dissolve in DMAC / PVP mixed solution at ℃, the ratio of the two solvents is 1:1, and the weight percent concentration of the polymer is 15%;

[0033] In the second step, in the above-mentioned polymer solution, isopropanol is added according to the ratio of 1:5 to the mixed solvent, stirred evenly, left to stand for defoaming, and a film-forming liquid is obtained;

[0034] In the third step, the thickness is 0.03mm, the surface density is 5g / m 2 The spunbonded polyester nonwoven fabric is dipped into the above-mentioned film-forming liquid, pulled out from the roll, and stayed in the air for 20s, then entered the water bath, stayed for 15min, and became a primary microp...

Embodiment 2

[0039] A preparation method of polyvinylidene fluoride-based microporous membrane:

[0040] In the first step, PVDF (Shanghai Sanaifu New Material Co., Ltd., brand FR907) and PVA (produced by Sinopec Sichuan Vinylon Plant, alcoholysis degree 99%, polymerization degree 1700) were mixed in the ratio of 5:1. Dissolved in the DMF / PVP mixed solution at 70°C, the ratio of the two solvents is 2:1, and the weight percent concentration of the polymer is 8%;

[0041] In the second step, in the above polymer solution, acetone is added in a ratio of 1:8 to the mixed solvent, stirred evenly, and left to defoam to obtain a film-forming liquid;

[0042] In the third step, the thickness is 0.4mm, the surface density is 10g / m 2 The polypropylene melt-blown nonwoven fabric is dipped into the above-mentioned film-forming liquid, pulled out from the roll, and stayed in the air for 60s, then entered the water bath, stayed for 20min, and became a primary microporous film;

[0043] The fourth step...

Embodiment 3

[0047] A preparation method of polyvinylidene fluoride-based microporous membrane:

[0048] In the first step, PVDF (Shanghai Sanaifu New Material Co., Ltd., brand FR907) and PVA (produced by Sinopec Sichuan Vinylon Factory, alcoholysis degree 99%, polymerization degree 1700) were mixed according to the ratio of 8:1 in the Dissolved in DMSO / PVP mixed solution at 60°C, the ratio of the two solvents is 2:1, and the weight percent concentration of the polymer is 10%;

[0049] In the second step, in the above polymer solution, add acetic acid according to the ratio of 1:6 to the mixed solvent, stir evenly and leave to defoam to obtain a film-forming liquid;

[0050] In the third step, the thickness is 0.2mm, the surface density is 10g / m 2 The spunbonded polyester nonwoven fabric is dipped into the above-mentioned film-forming solution, pulled out from the roll, and stayed in the air for 40s, then entered the water bath, stayed for 30min, and became a primary microporous membrane;...

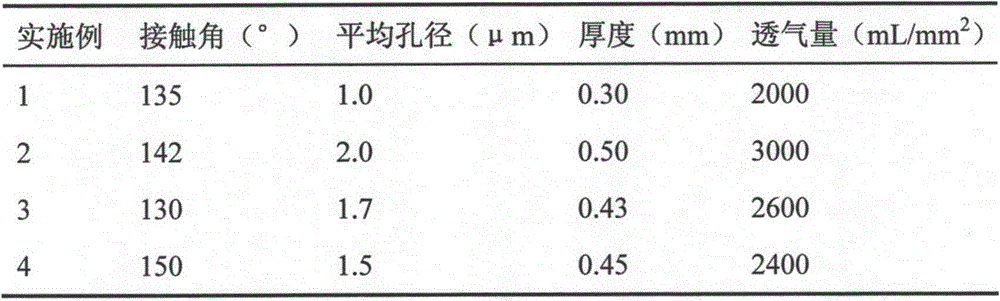

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com