A kind of polytetrafluoroethylene hollow fiber membrane and preparation method thereof

A polytetrafluoroethylene and fiber membrane technology, which is applied in the field of preparing polytetrafluoroethylene hollow fiber membranes, can solve the problems of inability to adapt to high-precision separation and filtration, large pore size, low bubble point, etc., and achieves low cost and simple preparation method. , Improve the effect of filtering precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

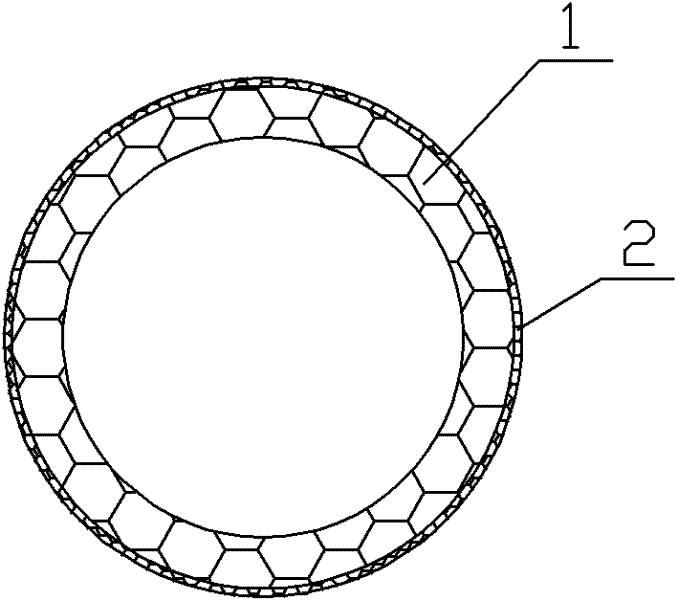

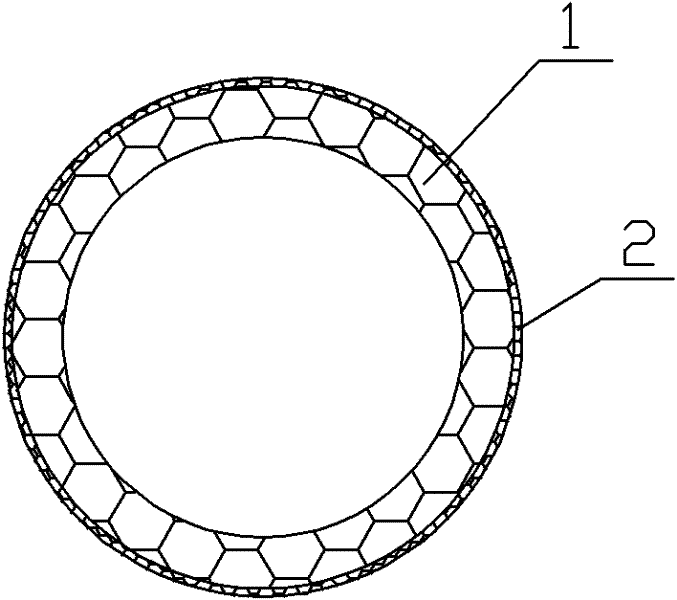

[0025] (1) Slit a PTFE flat membrane with a pore size of 0.02μm and a thickness of 5μm to obtain a microporous PTFE membrane wrapping tape with a width of 3mm;

[0026] (2) Immerse the microporous polytetrafluoroethylene film wrapping tape with a 10% solid content polyperfluoroethylene propylene (FEP) aqueous dispersion;

[0027] (3) Wrap the impregnated microporous PTFE membrane wrapping tape on the outer ring wall of the PTFE hollow fiber with a pore diameter of 0.5μm, an inner diameter of 1mm, and an outer diameter of 1.8mm. Heat treatment at 270℃ for 10s, get a bubble point of 5kg / cm 2 , 1kg / cm 2 A PTFE hollow fiber membrane with a flux of 2000L / m2·h under operating pressure.

Embodiment 2

[0029] (1) Slit a PTFE flat membrane with a pore size of 0.1 μm and a thickness of 20 μm to obtain a microporous PTFE membrane wrapping tape with a width of 10 mm;

[0030] (2) Immerse the microporous polytetrafluoroethylene film wrapping tape with a 20% solid content polyperfluoroethylene propylene (FEP) aqueous dispersion;

[0031] (3) Wrap the impregnated microporous PTFE membrane wrapping tape on the outer ring wall of the PTFE hollow fiber with a hole diameter of 1.0μm, an inner diameter of 2mm and an outer diameter of 2.8mm, and wrap it in two layers, and then wrap it at 285 Heat treatment at ℃ for 5s, get a bubble point of 2kg / cm 2 , 1kg / cm 2 A PTFE hollow fiber membrane with a flux of 3500L / m2·h under operating pressure.

Embodiment 3

[0033] (1) Slit a PTFE flat membrane with a pore size of 0.5 μm and a thickness of 100 μm to obtain a microporous PTFE membrane wrapping tape with a width of 20 mm;

[0034] (2) Immerse the microporous polytetrafluoroethylene flat membrane wrapping tape with 50% solid content polyperfluoroethylene propylene (FEP) water dispersion;

[0035] (3) Wrap the impregnated microporous PTFE membrane wrapping tape on the outer ring wall of the PTFE hollow fiber with a diameter of 2μm, an inner diameter of 3mm and an outer diameter of 4mm, and wrap it in five layers, and then at 300℃ Heat treatment at temperature for 8s, get a bubble point of 1.5kg / cm 2 , 1kg / cm 2 A PTFE hollow fiber membrane with a flux of 5000L / m2·h under operating pressure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com