A coating device for centrifugal deposition

A technology of coating equipment and centrifugal motor, which is applied in the direction of coating liquid on the surface, coating, etc., to achieve the effect of uniform coating, reducing filtration pore size, and ensuring coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

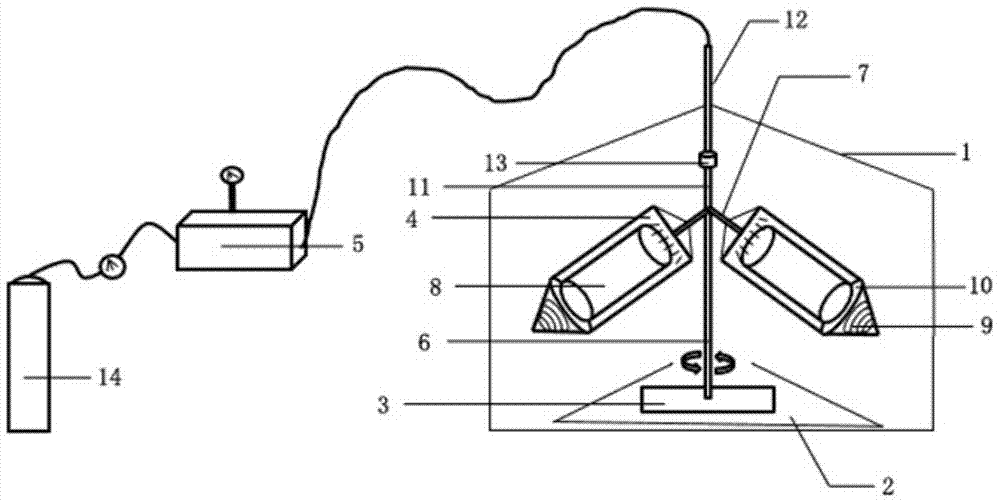

[0017] figure 1 is a schematic diagram of the structure of the coating equipment, such as figure 1 As shown, the coating equipment includes a casing 1 , a centrifugal base 2 , a centrifugal motor 3 , a rotor 4 and a coating liquid pressure tank 5 .

[0018] The centrifugal base is arranged inside the casing, and the centrifugal motor is fixed on the surface of the centrifugal base. The rotating shaft 6 of the centrifugal motor is provided with a strut 7 having a certain angle with the rotating shaft, and the angle between the strut and the rotating shaft is 50°. The rotor is arranged at the end of the pole, the top of the rotor is provided with a coating nozzle connected to the pipeline, the interior is provided with a ceramic filter element 8, the bottom is provided with a spring 9, and the bottom of the rotor is conical. A grid-like backing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com