Siderite active sand dephosphorization method

A kind of siderite and active technology, applied in the field of advanced treatment of micro-polluted source water, can solve the problems of high price and little prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Non-limiting examples are described below.

[0019] Choose siderite ore, the siderite content is not less than 30%;

[0020] Crush and screen siderite ore to obtain 0.25-0.5mm particles;

[0021] Fill the siderite particle filter material into a sand filter column constructed of a glass tube with a diameter of 30mm and a height of 1000mm;

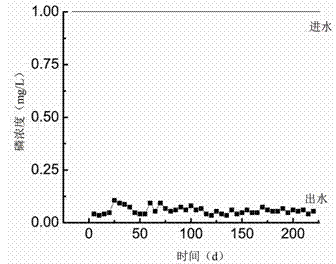

[0022] Prepare simulated water with a phosphorus concentration of 1.0mg / L, and operate it with a hydraulic retention time of 3 hours for wastewater phosphorus removal treatment;

[0023] Samples were taken every 5 days to detect the phosphorus concentration in the water, and the phosphorus concentration in the effluent remained below 0.1 mg / L after 225 days of operation (see figure 2 ), the phosphorus removal rate is greater than 90%, and the phosphorus concentration in the effluent reaches the second-class standard for surface water bodies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com