Sewage treatment system used in precision-investment casting technique

A sewage treatment system and investment casting technology, which are applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve environmental pollution, waste of water resources, high ammonia and chlorine content problems, to achieve the effect of saving water resources, good filtering effect, and reducing casting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

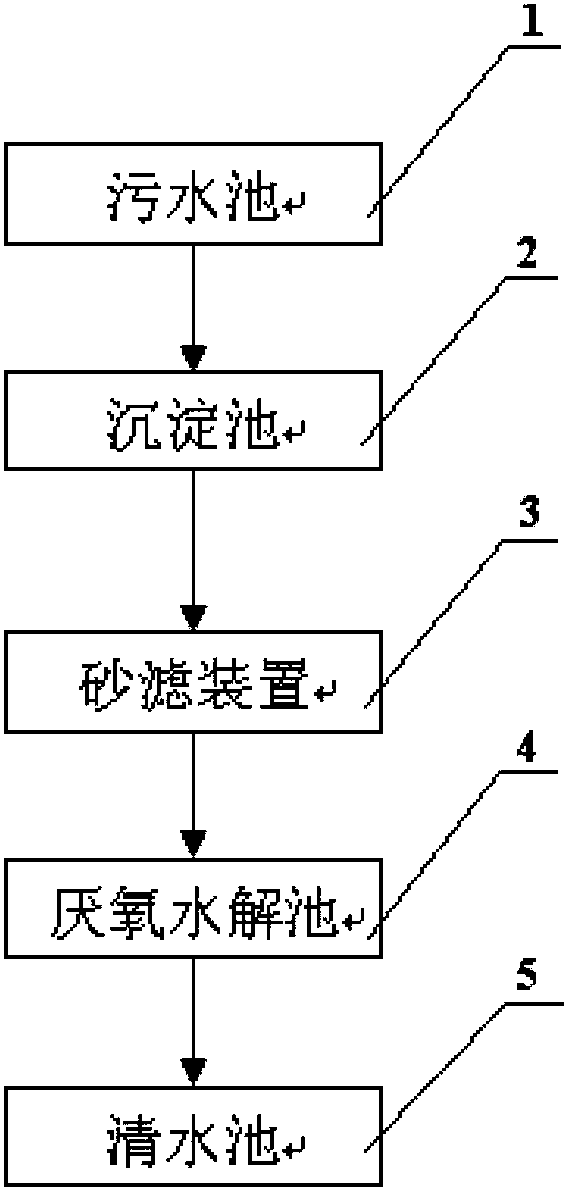

[0020] A sewage treatment system for an investment precision casting process, including a sewage pool 1 for collecting workshop sewage, and a sedimentation tank 2, a sand filter tank 3, an anaerobic hydrolysis tank 4, and clear water that are sequentially connected to the sewage pool 1 Pool 5, the sand filter 3 includes a primary sand filter and a secondary sand filter, the sand filter 3 is composed of an inverted trapezoidal open container and filter sand laid in the open container; The oxygen hydrolysis pool 4 is composed of a primary anaerobic hydrolysis pool, a secondary anaerobic hydrolysis pool, a third anaerobic hydrolysis pool and a fourth anaerobic hydrolysis pool.

[0021] The filter sand in the primary sand filter has a particle size of 100 mesh, and the filter sand in the secondary sand filter has a particle size of 200 mesh.

[0022] The working process of the present invention is as follows: the sewage from the investment precision casting workshop is collected i...

Embodiment 2

[0025] A sewage treatment system for an investment precision casting process, including a sewage pool 1 for collecting workshop sewage, and a sedimentation tank 2, a sand filter tank 3, an anaerobic hydrolysis tank 4, and clear water that are sequentially connected to the sewage pool 1 Pool 5, the sand filter 3 includes a primary sand filter and a secondary sand filter, the sand filter 3 is composed of an inverted trapezoidal open container and filter sand laid in the open container; The oxygen hydrolysis pool 4 is composed of a primary anaerobic hydrolysis pool, a secondary anaerobic hydrolysis pool, a third anaerobic hydrolysis pool and a fourth anaerobic hydrolysis pool. The particle size of the filter sand in the primary sand filter is 100 mesh, and the particle size difference of the filter sand in the secondary sand filter is 150 mesh.

[0026] The working process of the present invention is as follows: the sewage from the investment precision casting workshop is collect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com