Novel water collection and backwashing sand filter

A technology of sand filter and water collection, which is applied in the direction of gravity filter, loose filter material filter, filter separation, etc. It can solve the problems of easy damage of plastic filter head, short service life, increased backwash water volume, etc., and achieve reverse Easy to wash, less floor space, saving cleaning water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

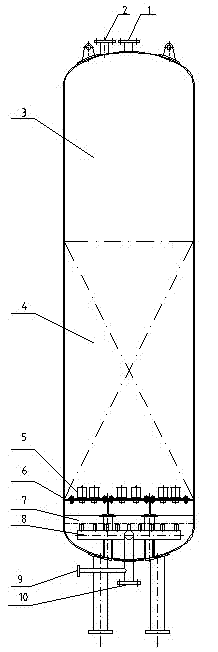

[0008] A new type of water collection and backwash sand filter, the sand filter includes a tank body 3, and the upper and lower parts of the tank body 3 are respectively provided with a water inlet 1, an exhaust port 2, a water outlet 10, and an air inlet 9. The middle part of the tank body 3 is a filter material layer 4, and the filter material layer 4 is provided with a sieve plate 6, and the sieve plate 6 is provided with a number of stainless steel filter caps 5 and homogeneous filter material. Below the plate 6 is a collecting chamber 7, in which a water collecting and air distribution pipe 8 is arranged, and the water collecting and air distribution pipe 8 communicates with the water outlet 10 and the air inlet 9.

[0009] filtering process

[0010] Open the water inlet 1 valve and the exhaust port 2 valve of the equipment, pour water into the tank body 3, and when the water overflows from the exhaust port 2, close the exhaust port 2 valve, open the water outlet 10 valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com