Method and device for cleaning bottoms of pools with sand beds

A sand bed, cleaning machine technology, applied in cleaning methods and utensils, cleaning methods using gas flow, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

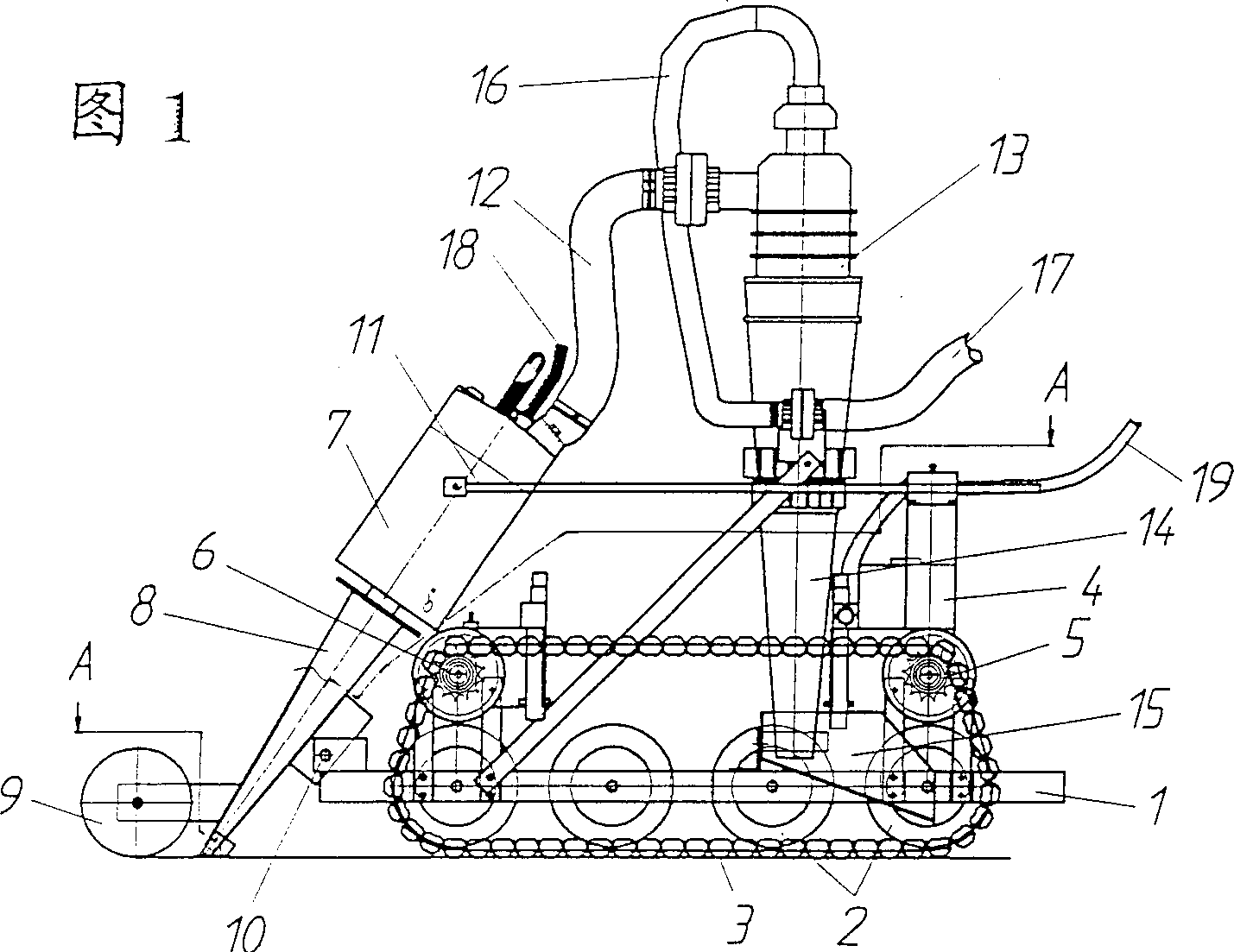

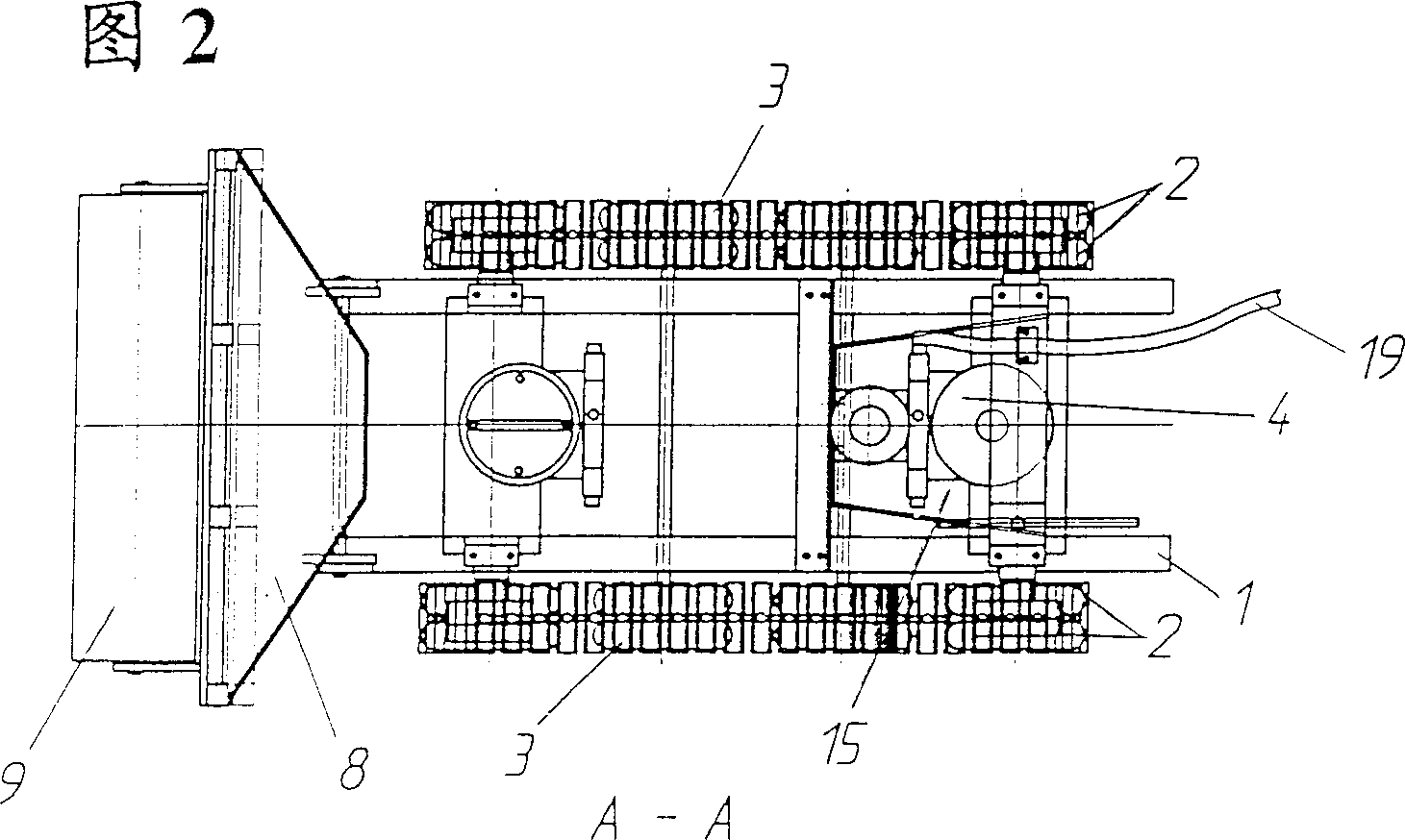

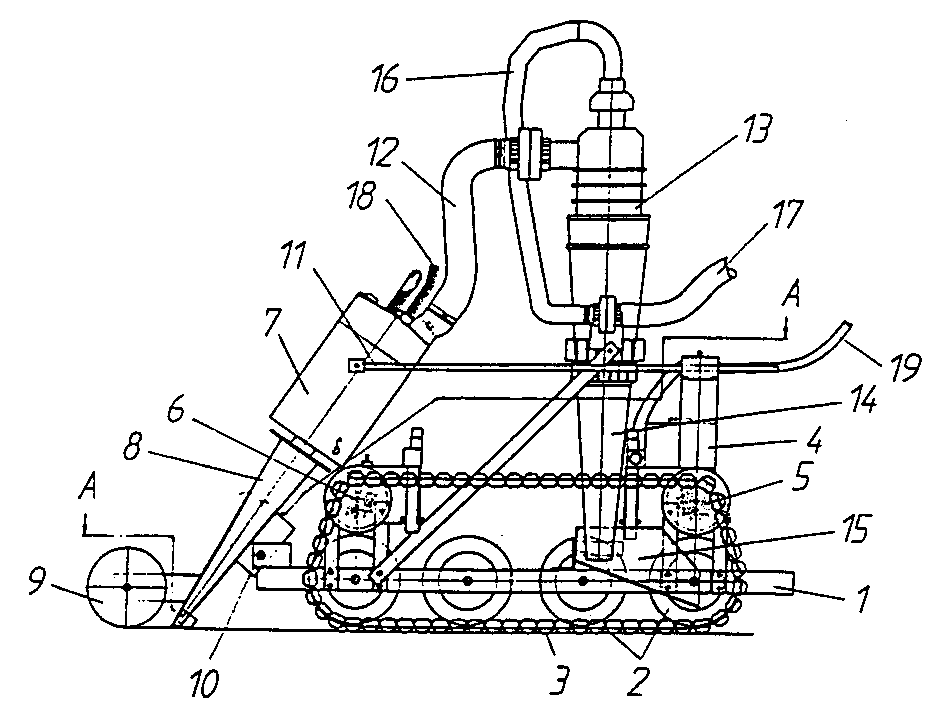

[0009] As shown in Figures 1 and 2, the chassis 1 is mounted on four pairs of double wheels 2, which are respectively surrounded by left and right crawlers 3 on each side of the cleaning machine. The track is driven by a fully enclosed worm gear motor 4, which is installed in the center of the rear of the chassis, through a short shaft protruding from both sides and equipped with a magnetic clutch, and drives each set of track by means of a sprocket 5 meshing with it. The front end of the cleaner is also provided with a common shaft with a magnetic clutch, which is connected to the sprocket 6 when the front is engaged with the track. The purpose of the magnetic clutch is to release or brake the track when cornering on the side the scrubber is going to turn towards. The front end of cleaning machine is provided with submerged pump 7, and submerged pump 7 is provided with suction nozzle 8, and the lower end of suction nozzle 8 widens outwards and extends to the whole width of cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com