Fiber composite filter body for sand control, sand filter tube and preparation method

A technology of fiber composite and filter body, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effects of uniform pore distribution, good permeability, and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: Take 1kg of proppant quartz sand 20-40 mesh (0.42-0.84mm) as an example to prepare a fiber composite filter body

[0047] (1) 2gKH-550, 100g epoxy resin (Guangzhou Dongfeng Chemical Industry Co., Ltd., model E-44 (6101), epoxy value (mol / 100g): 0.41-0.47), 5g hexamethylenetetramine , 10g of dibutyl ester was added successively to the tray containing the sand sample in the ratio of 2:100:5:10, mixed well, air-dried, crushed, and sieved to obtain resin-coated sand (proppant);

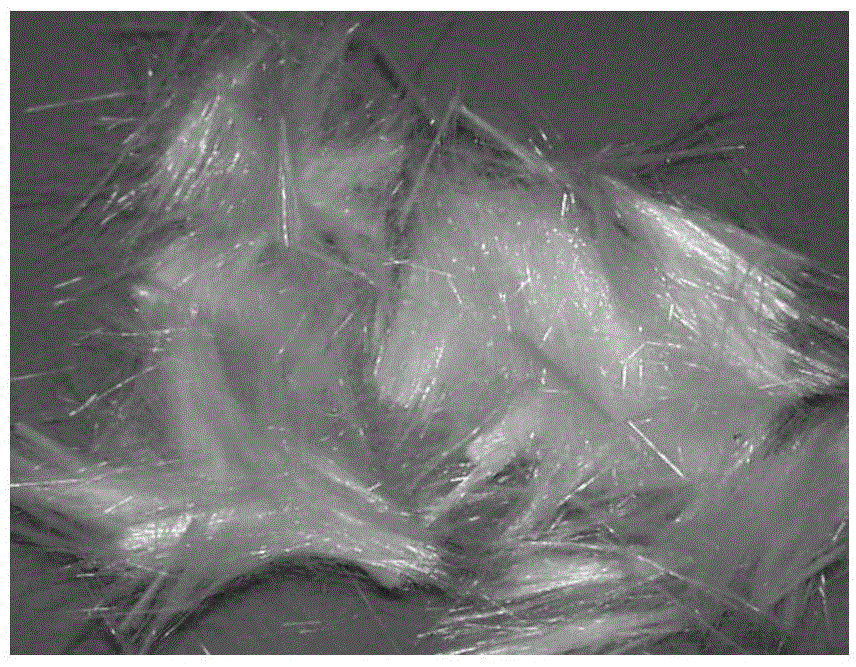

[0048](2) Get 0.0225gKH-550 and join in 15g glass fiber and carry out surface treatment; Make the glass fiber of surface treatment, as figure 1 shown.

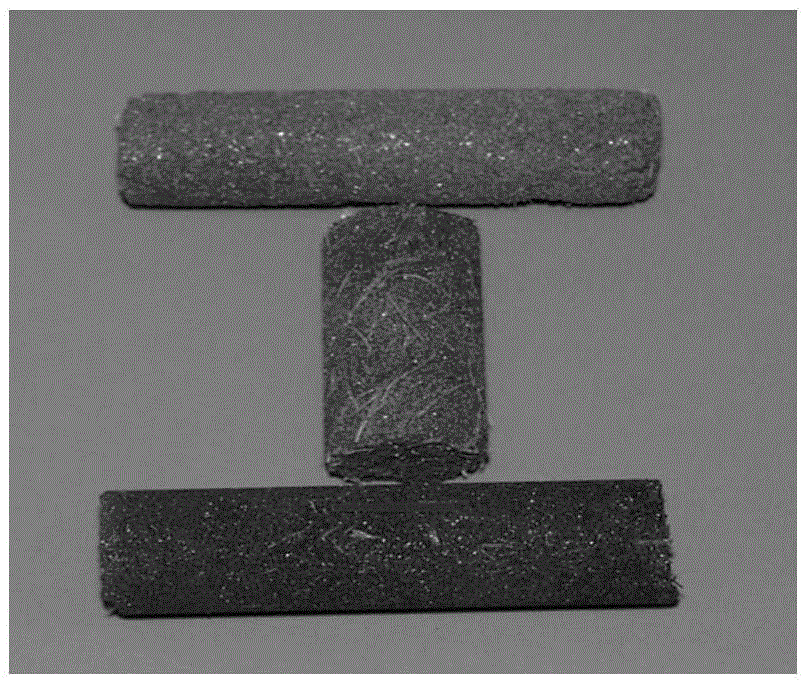

[0049] (3) Take 15g of surface-treated glass fiber, add it to 1kg of resin-coated sand by blowing air, put it into a mold, heat it at 65°C for 72h, take it out, and cool it to room temperature naturally to obtain a columnar fiber composite filter body ( like figure 2 shown).

[0050] Repeat the above operations to prepare 4 addi...

Embodiment 2

[0066] Embodiment 2: the fiber composite filter body is assembled into sand control sand filter pipe (such as Figure 4 shown)

[0067] The oil pipe is processed into a center pipe (about 10mm in hole diameter) with an overflow hole; the hollow cylindrical fiber composite filter body (such as image 3 ); put the finished fiber composite filter body on the central tube, cover the flow hole section of the central tube, and weld and fix the two ends with hoops.

[0068] The prepared sand filter tube for sand control is composed of a central tube 1 with flow holes 2 and a fiber composite filter body 3 covered on the central tube; both ends of the fiber composite filter body are fixed on the central tube by fixing pieces 4 On the flow hole section, the two ends of the central tube expose section 5 without holes. structured as Figure 5 shown. The fiber composite filter body is a hollow columnar filter body with a wall thickness of 25-30mm, and the inner diameter matches the oute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com