On-line back flushing sand filter

A sand filter and backwashing technology, which is applied in the field of sand filters, can solve the problems of reduced work efficiency, poor effect, time-consuming and laborious, etc., and achieve the effect of improving work efficiency, high backwash pressure, and good flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

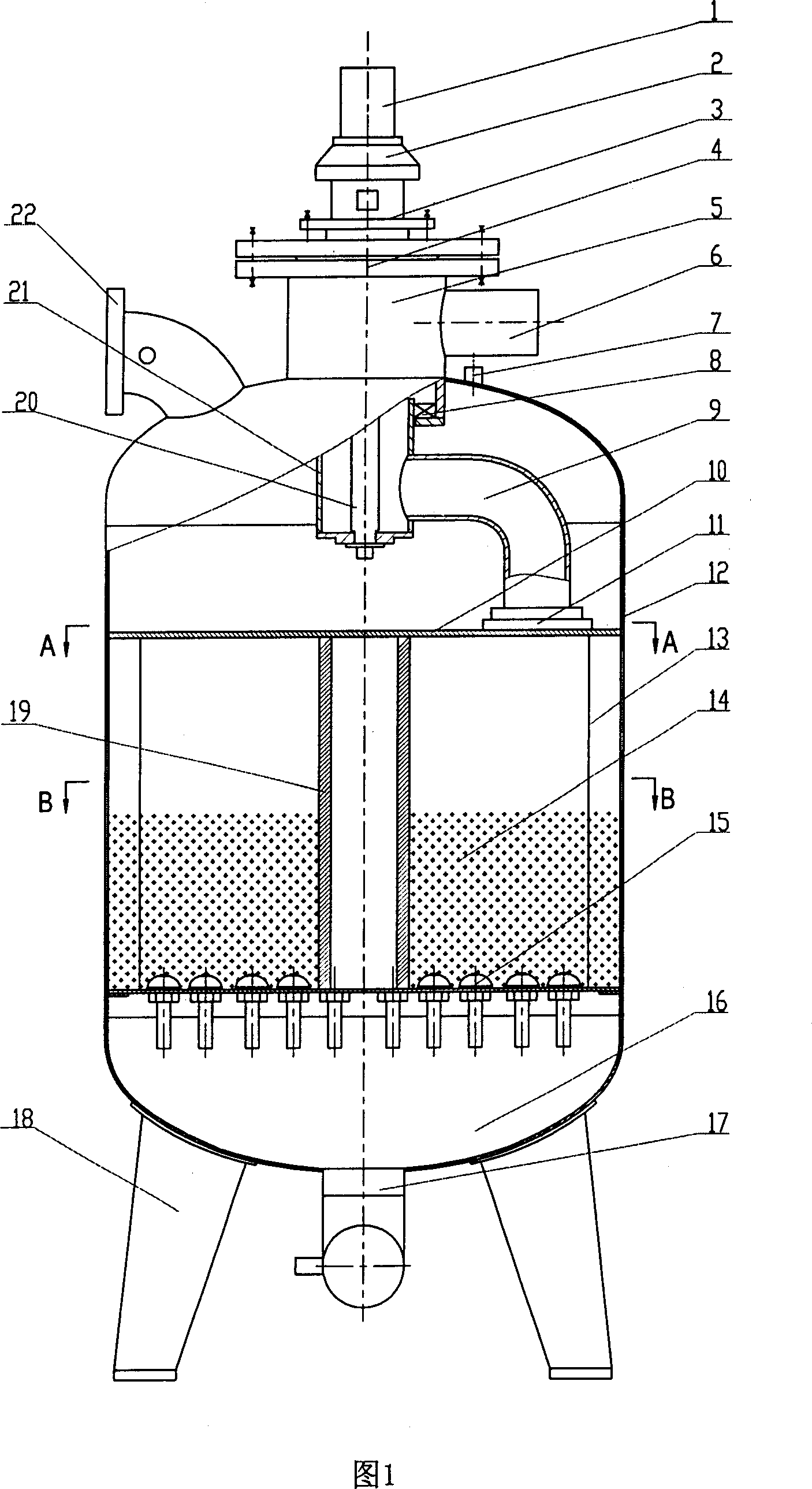

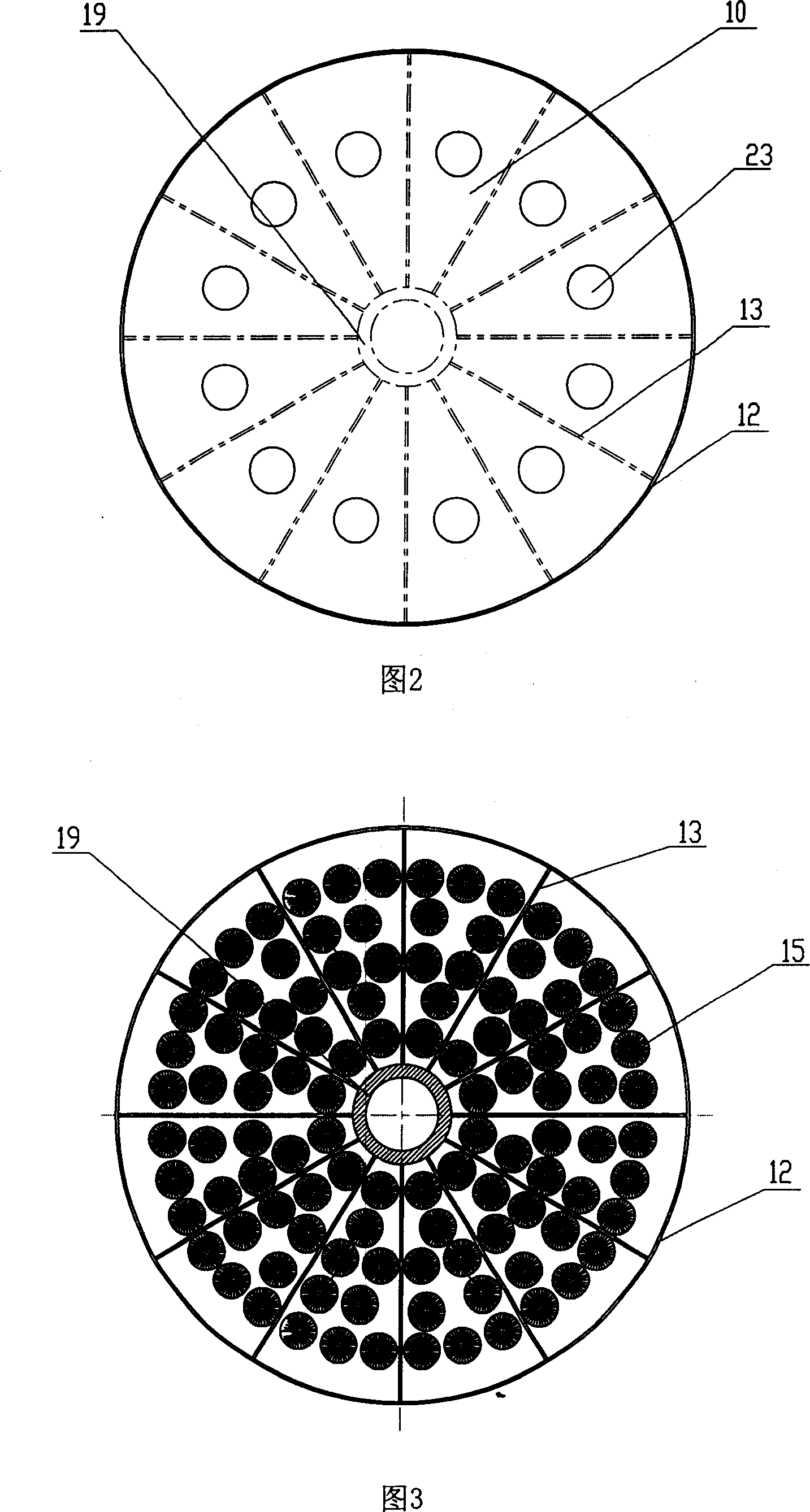

[0016] As shown in Figures 1 to 3, the sand filter includes a cylinder body 12 consisting of upper and lower heads and a middle cylinder, a water inlet 22, a sewage outlet and an exhaust port 7 are provided on the upper head, and A water outlet 17 is provided on the lower head, and a filter material layer 14 above the supporting water collection device 15 is arranged in the cylinder, and a water collection cavity 16 is formed in the cylinder below the filter material layer 14, and the entire cylinder Body 12 is supported by legs 18 below. In order to realize the backwashing function, a support pipe 19 is arranged axially in the middle part of the filter material layer 14, and a plurality of radially arranged partition plates 13 are sequentially fixed on the side of the support pipe 19, and the partition plates 13 divide the above filter materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com