Quartz-sand filter for deep treatment of sewage

A quartz sand filter, advanced treatment technology, applied in the direction of loose filter material filter, gravity filter, filter separation, etc., can solve the problem that the quartz sand is easy to be adhered by sticky dirt, the cost of the filter effect is not proportional, and the filter layer Unreasonable design and other problems, to achieve the effect of improving the filtering effect, low production cost, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

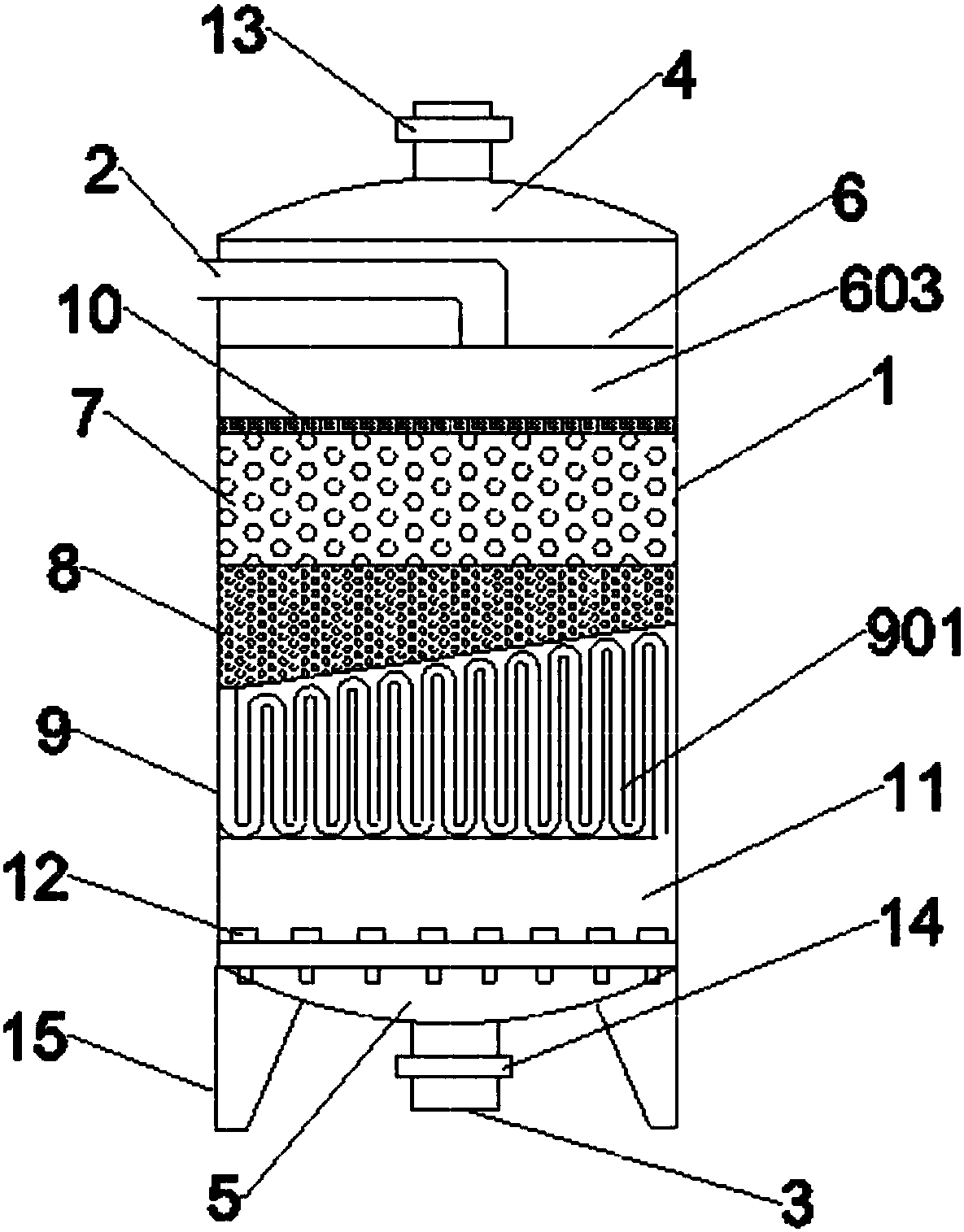

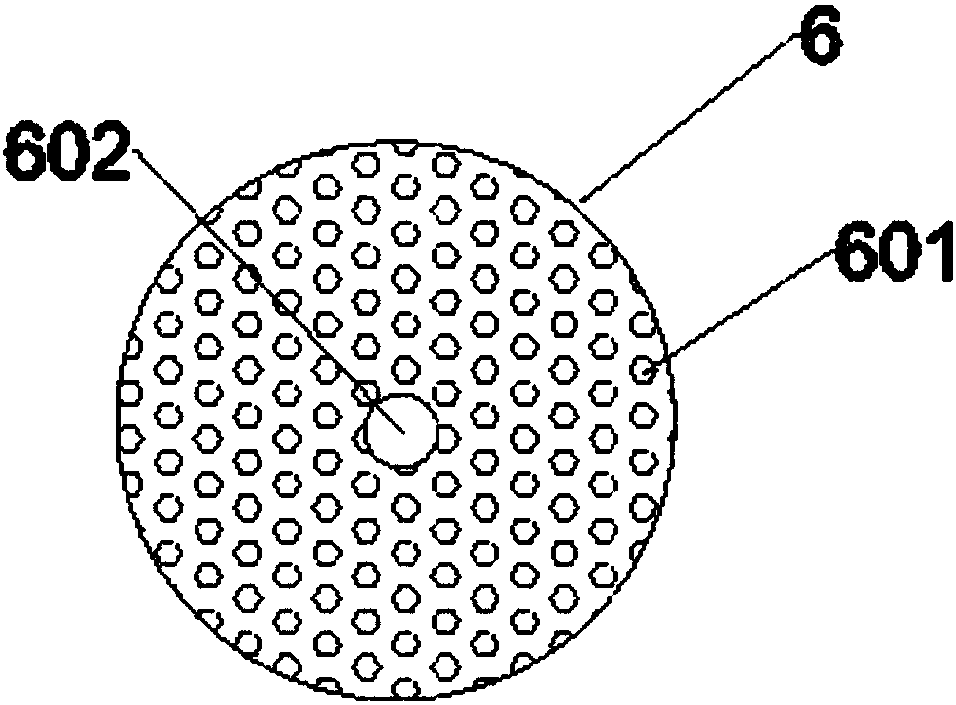

[0021] A quartz sand filter for advanced treatment of sewage, comprising a filter body 1, an upper head 4 and a lower head 5 which are sequentially arranged on the top and bottom of the filter body 1, respectively arranged on the upper head 4 and the lower head The upper manhole 13 and the lower manhole 14 at the top of the head 5, the water inlet 2 at the top left side of the filter body 1 and the water outlet 3 at the bottom of the lower manhole 14; the right side of the water inlet 2 is connected with a water distributor 6, The bottom of the water distributor 6 is evenly provided with a number of water leakage holes 601, and a coarse filter 10 is arranged at the bottom of the water distributor 6, and a quartz sand layer is arranged under the water distributor 6, and the quartz sand layer includes from top to bottom. The first-grade quartz sand layer 7, the second-grade quartz sand layer 8, and the third-grade quartz sand layer 9, the quartz sand particle size of the first-gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com