Gas phase oxidation-liquid phase reduction method for absorbing and removing nitrous oxides in exhaust air

A nitrogen oxide and gas-phase oxidation technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems that hinder the application of ACF catalytic oxidation of NO, to avoid catalyst deactivation, reduce waste liquid treatment costs, The effect of reducing governance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

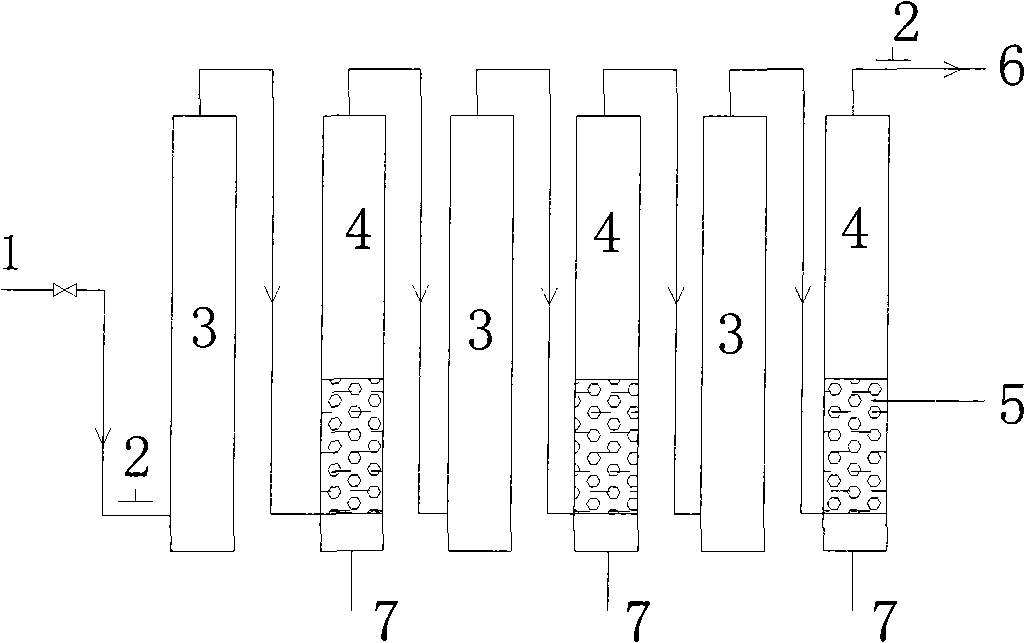

[0030] The NOx waste gas is passed into the oxidation tower 3 through O 2After oxidation, it enters the absorption tower from the bottom of the absorption tower 4 and undergoes reductive absorption reaction with the absorption liquid 5 through bubbling. After the reaction, the gas is discharged from the tower top, the exhaust gas undergoes three-stage oxidation-reduction absorption treatment, and the tail gas is evacuated through the tail gas discharge port 6. The oxidation tower 3 has a diameter of 40mm, a height of 300mm, and a total oxidation volume of 2.0L. The bubble absorption tower 4 has a diameter of 40mm and a height of 600mm. Exhaust gas contains 1907ppmvNOx, saturated water vapor and about 20% O at room temperature 2 , The reduction and absorption solution 5 is added in 200ml, and its composition is 4%(W / W)NaOH and 8%(W / W)CO(NH 2 ) 2 . Gas flow: 0.08m 3 / h, reaction under normal temperature and pressure, the inlet and outlet NOx concentration is detected and analyzed by...

Embodiment 2

[0032] The reactor and operating conditions are the same as in Example 1. The exhaust gas contains NOx 1330ppmv, saturated water vapor and about 20% O at room temperature. 2 , The reduction and absorption solution 5 is added in 200ml, and its composition is 4%(W / W)NaOH and 8%(W / W)CO(NH 2 ) 2 , Gas flow rate: 0.08m 3 / h, reaction under normal temperature and pressure, the inlet and outlet NOx concentration is detected and analyzed by the flue gas analyzer (testo 350-XL).

Embodiment 3

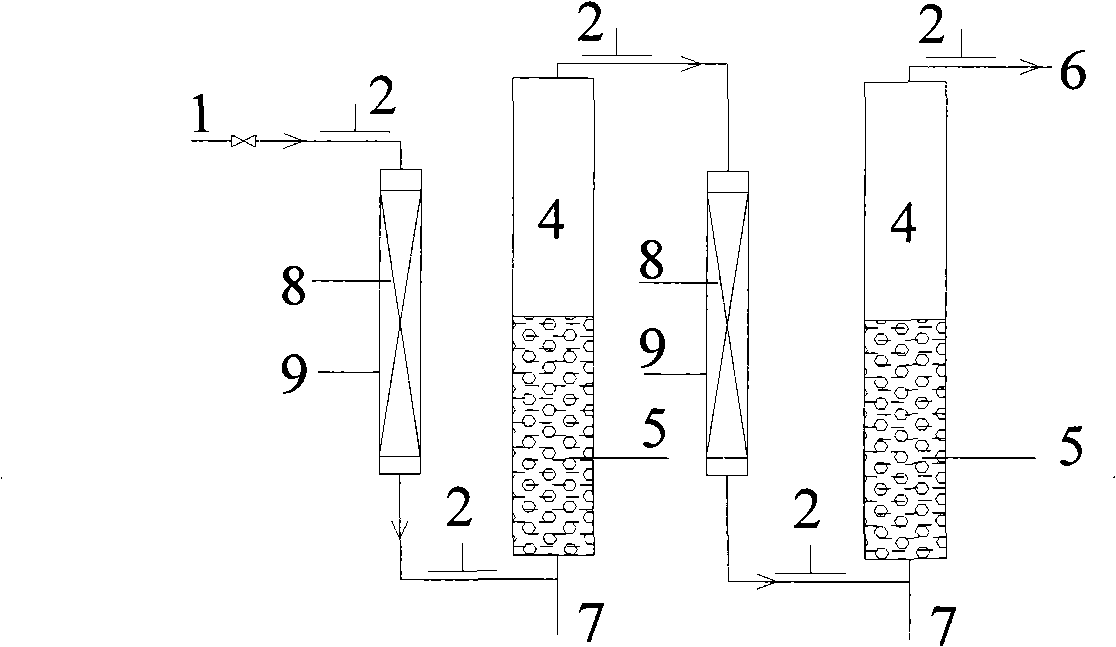

[0034] The waste gas passes through O in the oxidation tower 3 2 After oxidation, it enters the absorption tower 4 to react, undergoes one-stage oxidation, reduction and absorption treatment, and the tail gas after absorption is tested and emptied after treatment. The oxidation tower 3 has a diameter of 80mm and a height of 600mm (oxidation volume of 3.0L), and the bubbling absorption tower 4 has a diameter of 40mm and a height of 600mm. The exhaust gas contains 1785ppmvNOx, saturated water vapor and about 20% O at room temperature 2 , The reduction and absorption solution 5 is added in 300ml, containing 1%(W / W)NaOH and 8%(W / W)CO(NH 2 ) 2 , Gas flow rate: 0.08m 3 / h, reaction under normal temperature and pressure, the inlet and outlet NOx concentration is detected and analyzed by the flue gas analyzer (testo350-XL) at sampling port 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com