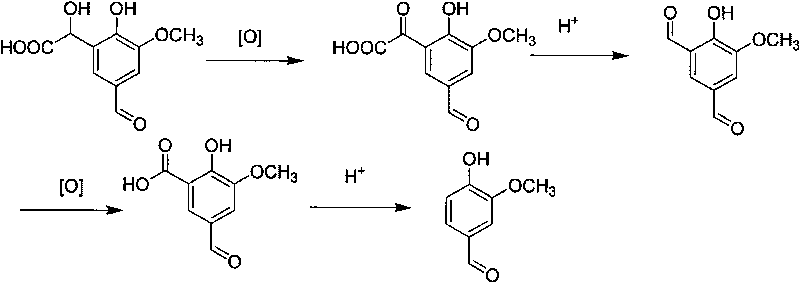

Method for converting 2-hydroxyl-3-methoxy-5-aldehyde mandelic acid into vanillin

A technology of aldehyde vanillin and methoxy, which is applied in the field of vanillin preparation to achieve the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 macroporous resin static adsorption

[0040] Weigh 10 grams of D101 macroporous adsorption resin (purchased from Bengbu Liaoyuan New Material Co., Ltd.), put it into a 500ml single-mouth bottle, add 350ml pH3. Cr 6100mg / L, shake in a constant temperature shaking tank at 25-30°C for 1 hour, filter out the resin, and pass the detection of COD Cr Dropped to 985mg / L. Then add 5% (w / v) sodium hydroxide solution 250ml to carry out desorption, obtain the aromatic compound through enrichment, its COD Cr It is 14331mg / L.

Embodiment 2

[0041] Embodiment 2 macroporous resin dynamic adsorption

[0042] In a Add 400ml of XDA-1 macroporous adsorption resin (purchased from Xi’an Electric Power Resin Factory) into the chromatography column, and use electric wire heating method outside the column to keep the temperature inside the column at 35±3°C. First, add a certain amount of Glyoxylate vanillin production wastewater was submerged in the resin, and vanillin production wastewater was added from the top at a rate of 500ml per hour after 60 minutes, and the wastewater after adsorption treatment was collected from the bottom at the same time, and the cumulative amount of wastewater that could be treated reached 10908ml. After testing the COD of wastewater before adding Cr is 5827mg / L, COD of wastewater after adsorption Cr It is 857mg / L. Then add 5% (w / v) sodium hydroxide solution 250ml in 1 hour to carry out desorption, obtain the aromatic compound through enrichment, its COD Cr It is 12509mg / L.

Embodiment 3

[0044] In a 5L autoclave, add 3.5 kilograms of waste water containing 2-hydroxyl-3-methoxyl-5-formyl mandelic acid desorbed from resin, which contains 2-hydroxyl-3-methoxyl-5-formyl almond Acid about 45%. Adjust the pH value to be greater than 11, and then add 150 grams of copper oxide. Seal the autoclave, raise the temperature to 125-150°C for reaction, take a sample and analyze the conversion of 2-hydroxy-3-methoxy-5-formylmandelic acid to over 95%, and then stop the reaction. Cool to below 50°C, filter to obtain a clear liquid containing 2(2-hydroxy-3-methoxy-5-formyl)phenyl-2-oxoacetic acid, and the filtered clear liquid can be directly used for the next decarboxylation reaction.

[0045] Add the above clear liquid into a 5L three-necked flask, add 50% sulfuric acid to adjust the pH value to 4-5, and stir and cool to crystallize. After drying, 129 grams of 5-formyl vanillin were obtained, with a purity of 96.5% and a yield of 102.9% (note: the desorption wastewater itsel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com