Method for preparing manganese sulfate solution by using sulphur dioxide gas leach manganese dioxide ore

A manganese sulfate solution, sulfur dioxide technology, applied in manganese sulfate and other directions, can solve the problems of affecting the absorption rate of sulfur dioxide, large volume flow, waste of sulfur resources, etc., and achieve continuous, stable and high-efficiency production, low grade requirements, and high utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

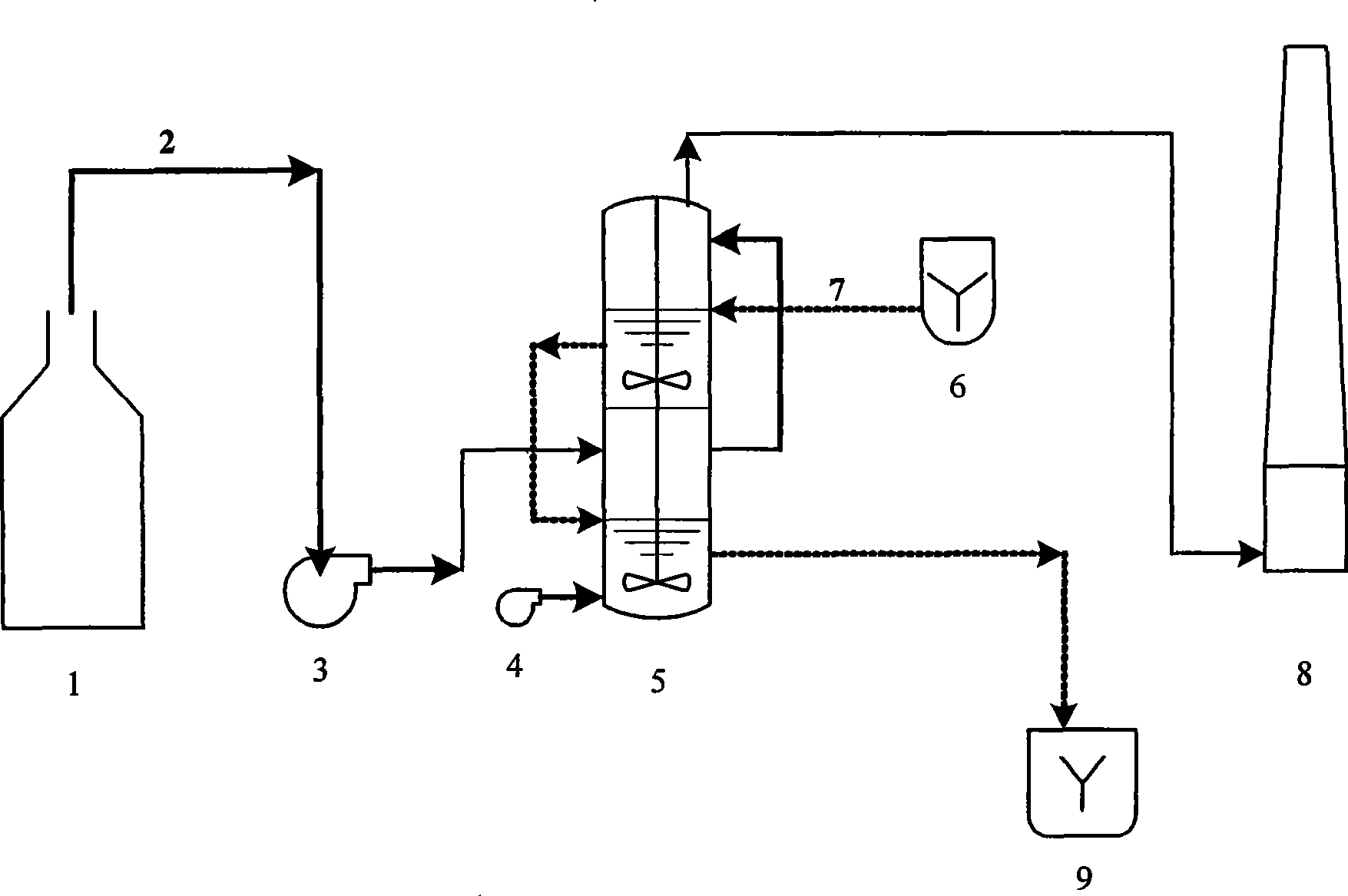

[0051] In this embodiment, the reactor 5 is a device comprising two-stage absorption and leaching reaction chambers arranged in series up and down directly connected by pipelines. Sulfur dioxide gas comes from sulfur roasting generation system 1, and the sulfur dioxide gas production is 6000Nm 3 / h, after cooling down to about 80°C through heat exchange, it is sent into the absorption reactor 5 by the blower 3 through the pipeline 2 at a pressure of 8000Pa. Pyrolulurite with a particle size of less than 100 mesh and water are prepared in the pulp tank 6 equipped with agitator to make a pulp with a liquid-solid ratio (mass ratio) of 2:1, and then sent to the absorption reactor 5 through the pulp pipeline 7 by a pump. Oxygen is sent into the absorption reactor 5 by the blower 4 . In the reactor, sulfur dioxide gas and oxygen are continuously sent into the second-stage absorption and leaching reaction chamber of the reactor respectively, and enter the pulp that overflows and des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com