Treatment method for waste incineration power plant leachate and device thereof

A landfill leachate and waste incineration technology, which is applied in anaerobic digestion treatment, sustainable biological treatment, chemical instruments and methods, etc., can solve the problems of high power consumption, inability to enter the actual industrialization stage, and easy poisoning of catalysts. The effect of reducing floor space, small floor space and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] 1. Method

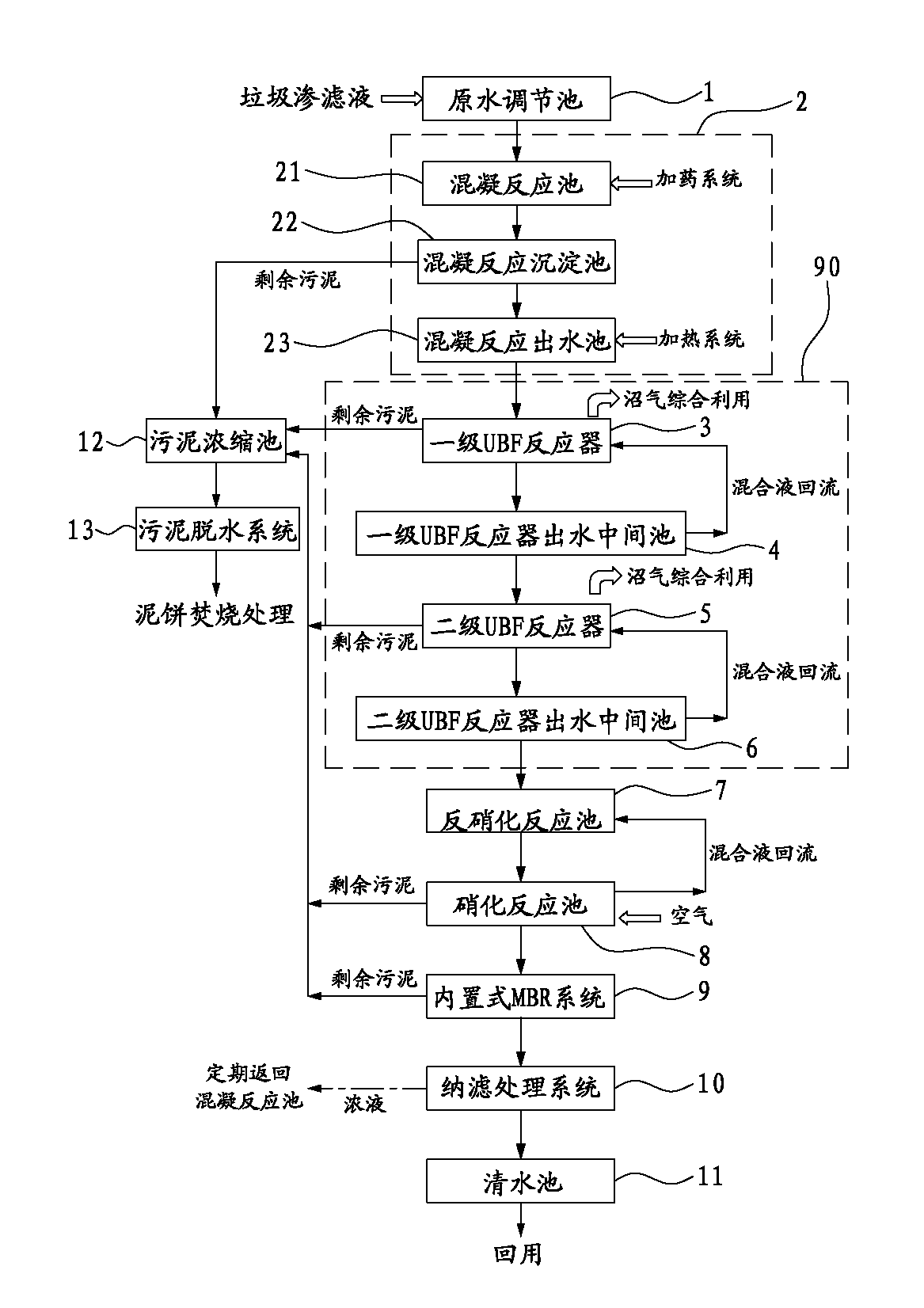

[0040] Such as figure 1 Shown, the present invention is a kind of waste incineration power plant leachate treatment method, and it comprises the following steps:

[0041] 1. The raw liquid of landfill leachate enters the raw water adjustment tank 1 to stabilize the water volume and water quality, so that the raw liquid of landfill leachate can be adjusted evenly, which plays a role of uniform quality and quantity, and prepares for the subsequent reaction;

[0042]2. Send the effluent leachate from the raw water adjustment tank 1 into the coagulation reaction system 2, and add a flocculant (quicklime polyferric chloride) to the coagulation reaction tank 21 of the coagulation reaction system 2 for flocculation reaction. After the reaction, it enters the coagulation reaction sedimentation tank 22, and the metal ions and suspended matter are separated out by the flocculation reaction;

[0043] 3. The effluent of the coagulation reaction sedimentation tank 22 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com