Comprehensive utilization method of chemical polishing waste phosphoric acid

A technology of chemical polishing and waste phosphoric acid, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of large mud production and high landfill treatment costs, achieve high utilization rate, reduce landfill costs, and reduce production costs. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

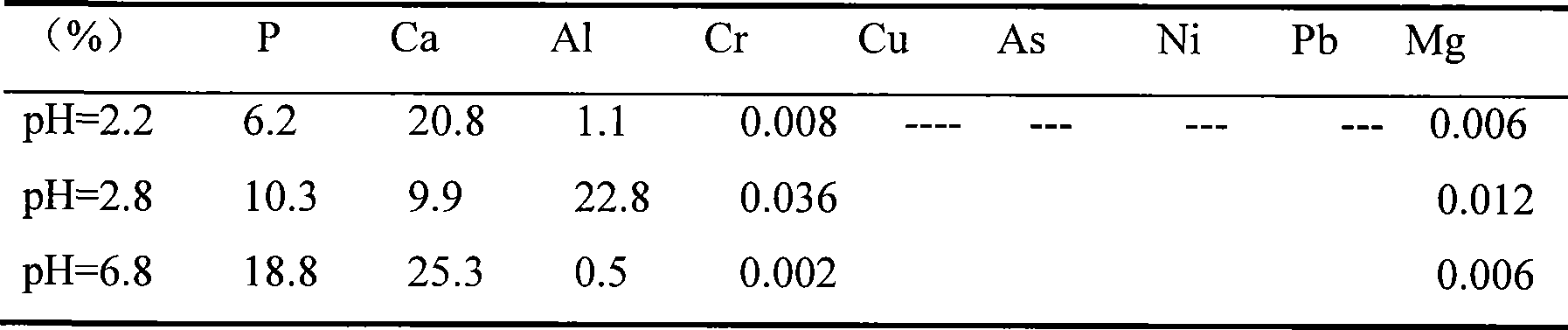

[0026] Take chemical polishing waste phosphoric acid 100mL, its relative density is 1.42, wherein total phosphorus content is 175g / L, aluminum content 18g / L, Ni content 328mg / L, add 300mL water to above-mentioned chemical polishing waste phosphoric acid, make its relative density dilute to 1.1, then slowly add milk of lime with a weight percentage of 20%, react to pH=2.2, filter with suction, discard the filter residue, continue to add milk of lime to the filtrate to adjust the pH to 2.8, and filter with suction, the filter residue is fertilizer grade calcium hydrogen phosphate , the above two steps control the reaction temperature to 50-80°C, continue to adjust the pH of the filtrate to 6.8 with lime milk, control the reaction temperature to 50-60°C, and perform suction filtration to obtain feed grade calcium hydrogen phosphate.

[0027] The obtained filter residue solid was dried at 120° C., and the mass of each solid was determined to be 17.9 g, 11.7 g, and 73.3 g respective...

Embodiment 2

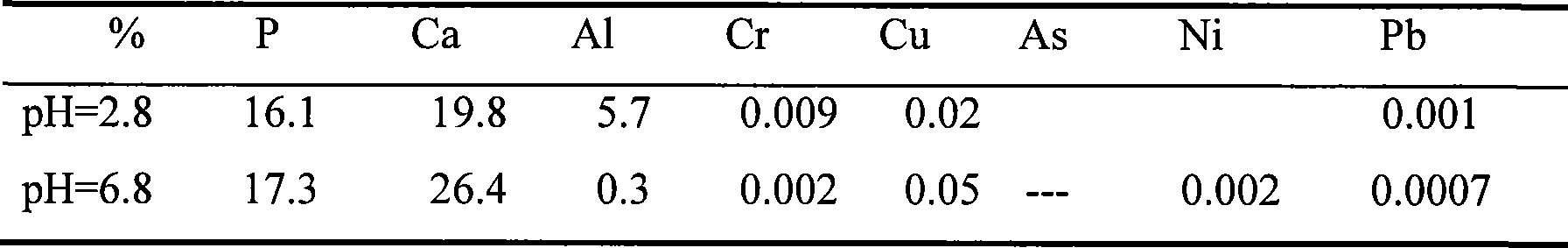

[0031] Take chemical polishing waste phosphoric acid 100mL, its relative density is 1.67, and phosphorus content is 195g / L, dilute above-mentioned chemical polishing waste phosphoric acid to relative density and be 1.12, slowly add the milk of lime that weight percentage is 10%, control reaction temperature 50-80°C, react to pH=2.8, filter with suction, the dry weight of the filter residue is 40.4g, continue to neutralize the filtrate with milk of lime, control the reaction temperature at 50-60°C, neutralize to pH=6.8, filter with suction, and filter the residue Dry weight 64.9g. The weight percentage of each composition in each solid is as follows:

[0032]

[0033] In the above-mentioned second stage of precipitated solids, the phosphorus (P) content and calcium (Ca) content can both reach the national feed grade calcium hydrogen phosphate standard.

[0034] Adjust the pH of the filtrate obtained in the second step to 9.5 with milk of lime, and precipitate out. The preci...

example 3

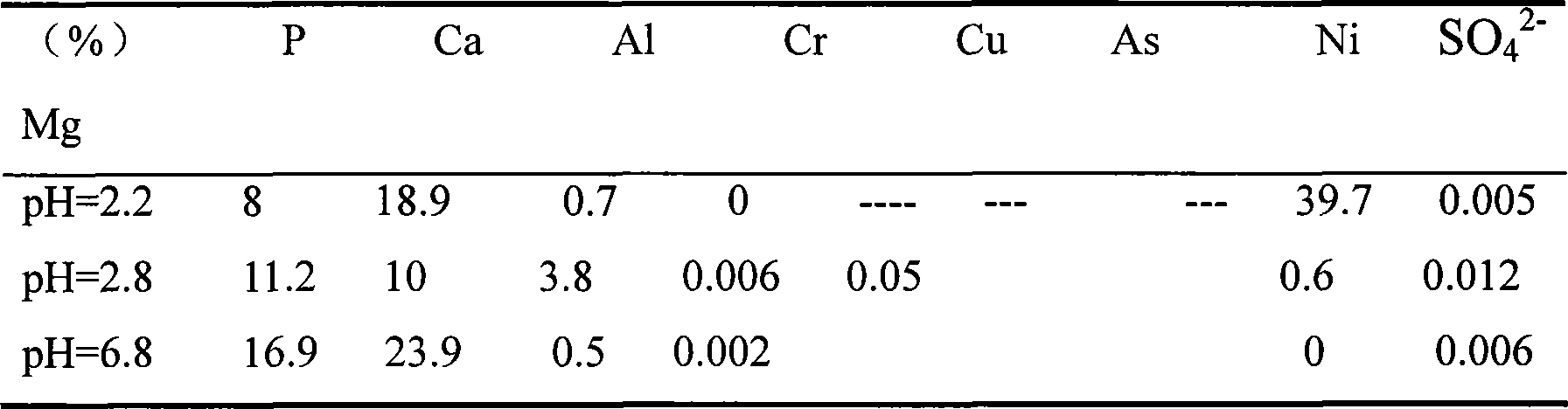

[0036] Take chemical polishing waste phosphoric acid 100mL, its relative density is 1.37, wherein total phosphorus content is 125g / L, aluminum content is 6.4g / L, SO 4 2-Content 47.6g / L, containing black suspended solids, add 300mL water to the above chemical polishing waste phosphoric acid to dilute its relative density to 1.09, then slowly add milk of lime with a weight percentage of 20%, react until pH = 2.2, Suction filtration, the filter residue is discarded, continue to add lime milk to the filtrate to adjust the pH to 2.8, and suction filtration, the obtained filter residue is fertilizer grade calcium hydrogen phosphate, the above two steps keep the reaction temperature at 50-80 ° C, and the obtained filtrate is adjusted to the pH with lime milk To 6.8, control the reaction temperature to 50-60°C, filter with suction, and the obtained filter residue is feed grade calcium hydrogen phosphate.

[0037] The obtained filter residue solid was dried at 120° C., and the mass of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com