Production process for producing organic fertilizer through concentrating biogas slurry by using multistage membrane separation technology

A production process and membrane separation technology, applied in the preparation of organic fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve problems such as low concentration efficiency, membrane fouling, difficult to eradicate membrane clogging, complex pretreatment process, etc., to reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

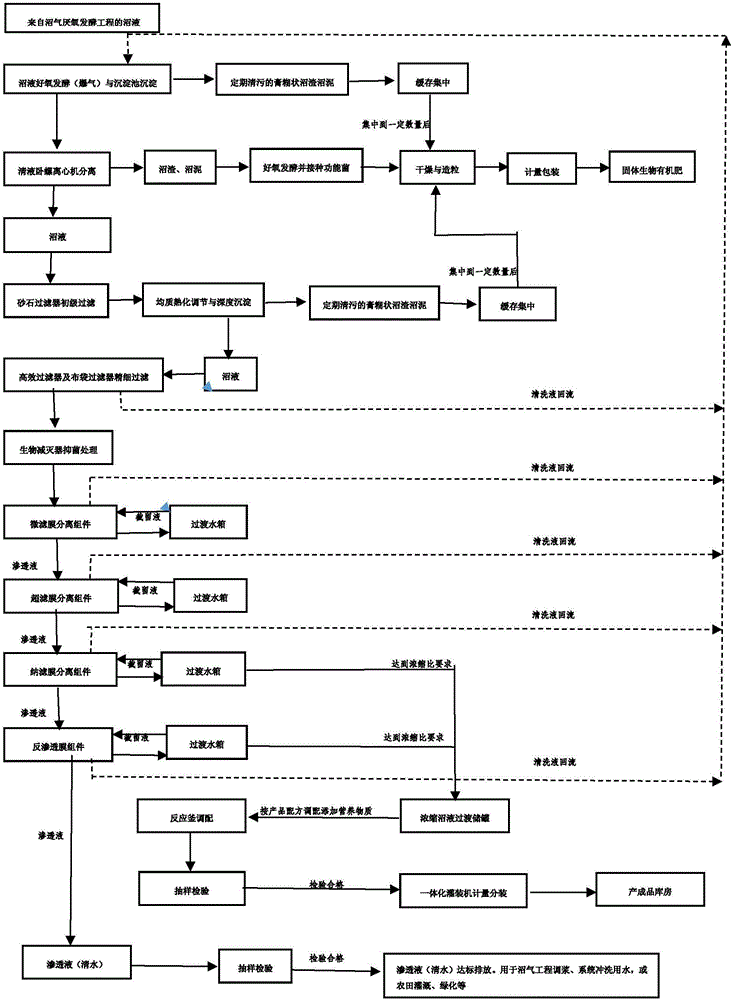

[0056] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments thereof.

[0057] like figure 1 As shown, the production process of using biogas slurry multi-stage membrane separation and concentration technology to manufacture organic fertilizer includes the following steps:

[0058] (1) Preprocessing

[0059] ① Precipitation and aerobic fermentation: The biogas slurry after anaerobic fermentation is discharged from the anaerobic fermentation tank to the sedimentation tank for natural precipitation for no less than 24 hours, so that the large solids in the biogas slurry can be fully precipitated; The biogas slurry is subjected to aerobic fermentation for not less than 24 hours, to transform the ammonium nitrogen in the biogas slurry and further degrade the organic matter that cannot be decomposed by anaerobic fermentation;

[0060] ②Solid-liquid separation: The biogas slurry after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com