Industrial exhaust gas desulfurizer

A desulfurization device, a technology for industrial exhaust, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of polluting the atmosphere and the environment, favoring loss of human beings, hindering sustainable social development, etc., to reduce consumption, reduce The effect of wastewater treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

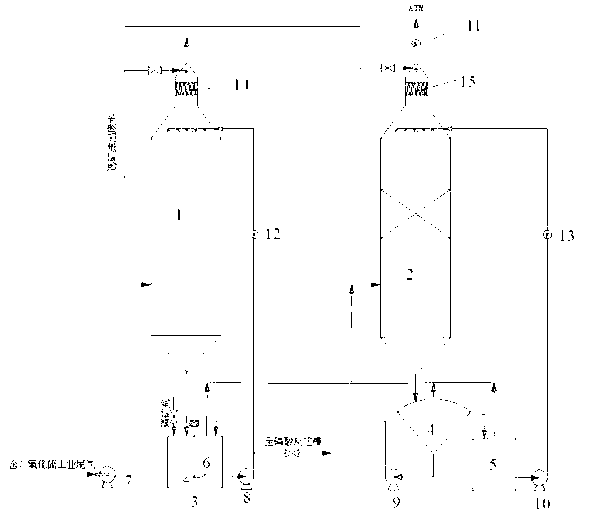

[0018] Embodiment: Take the 200,000-ton / year sulfuric acid plant of a certain company to use this method as an example, and the tail gas emission is 43000Nm 3 / h, the sulfur dioxide emission index is about 300ppm, and the temperature is about 65°C, which is directly discharged into the atmosphere because it is less than the national sulfur dioxide emission standard ≤ 420ppm. Today, the new national emission standard ≤140ppm will be implemented on October 1, 2013. The exhaust gas produced according to the original design can no longer meet the standard emission, and the exhaust gas of the device must be treated one step before it can be discharged.

[0019] The company adopts the device of the present invention and includes: desulfurization tower 1, phosphate pulp circulation tank 3, washing tower 2, settling tank 4 and clear night tank 5; The system is connected to the phosphate slurry circulation tank 3 through the phosphate slurry circulation pump 8, and the outlet at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com