Comprehensive electroplating wastewater treatment method

A technology for electroplating wastewater and treatment methods, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of substandard effluent and difficult recovery of heavy metals, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

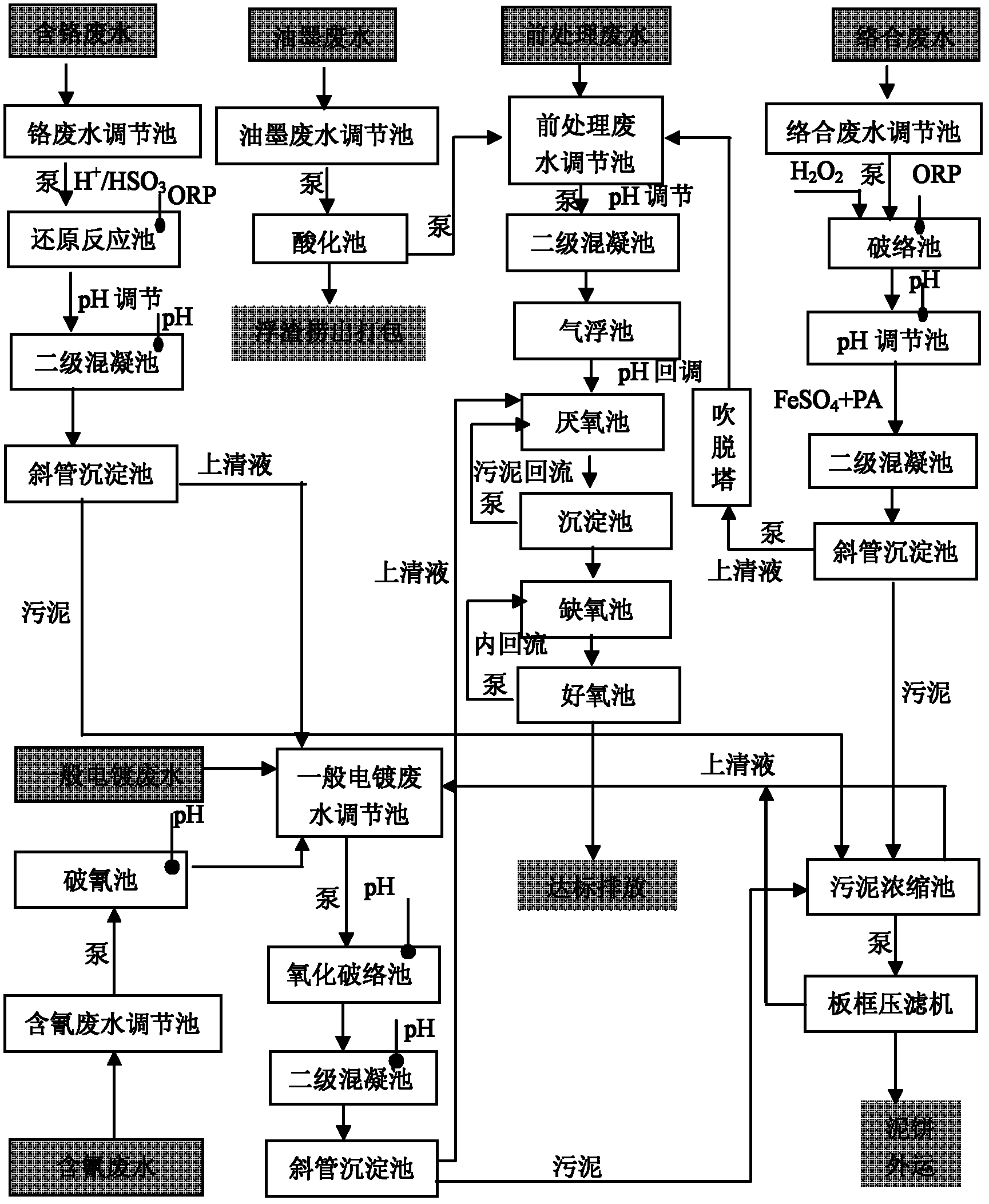

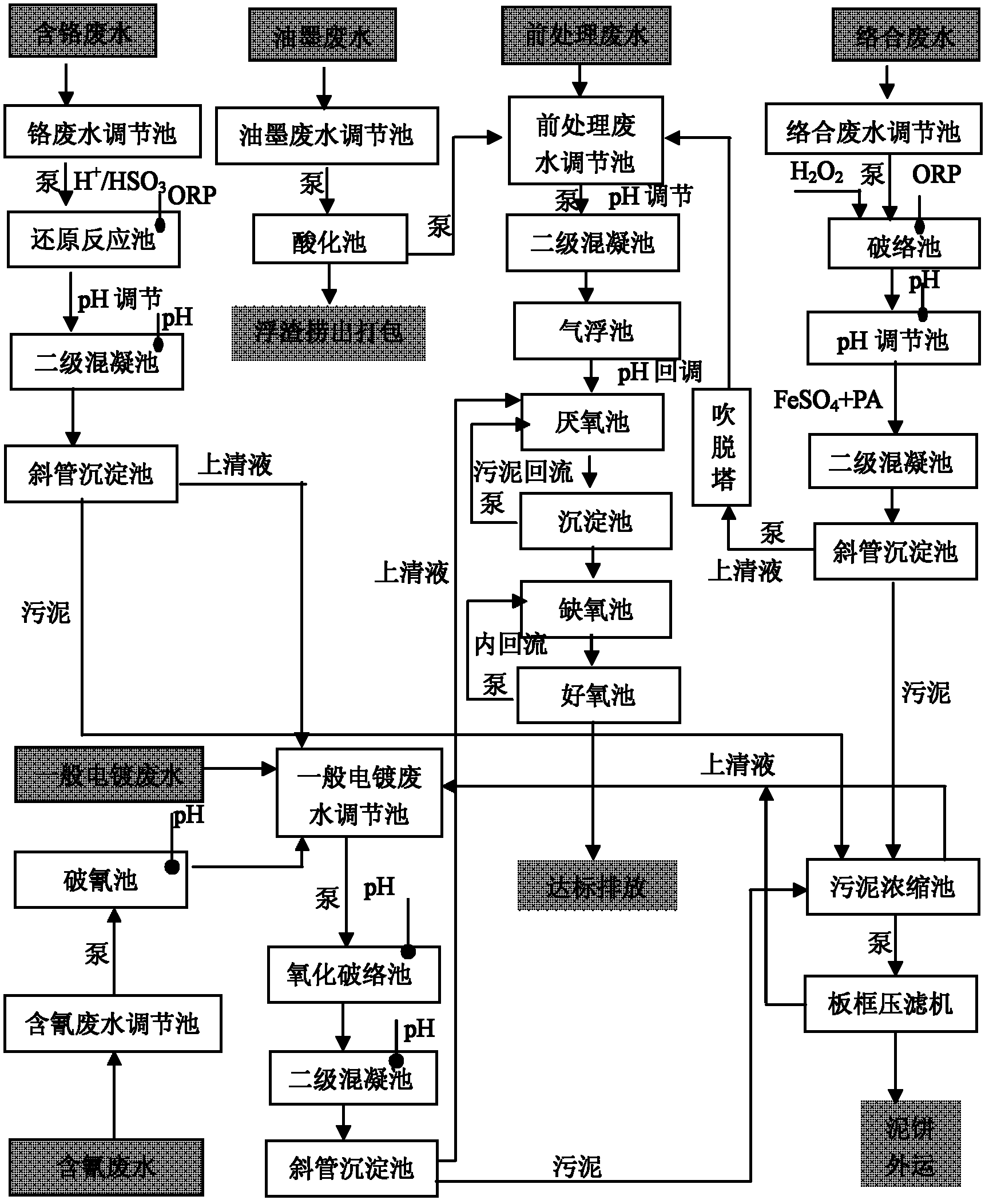

[0040] Below according to accompanying drawing and example the present invention will be further described:

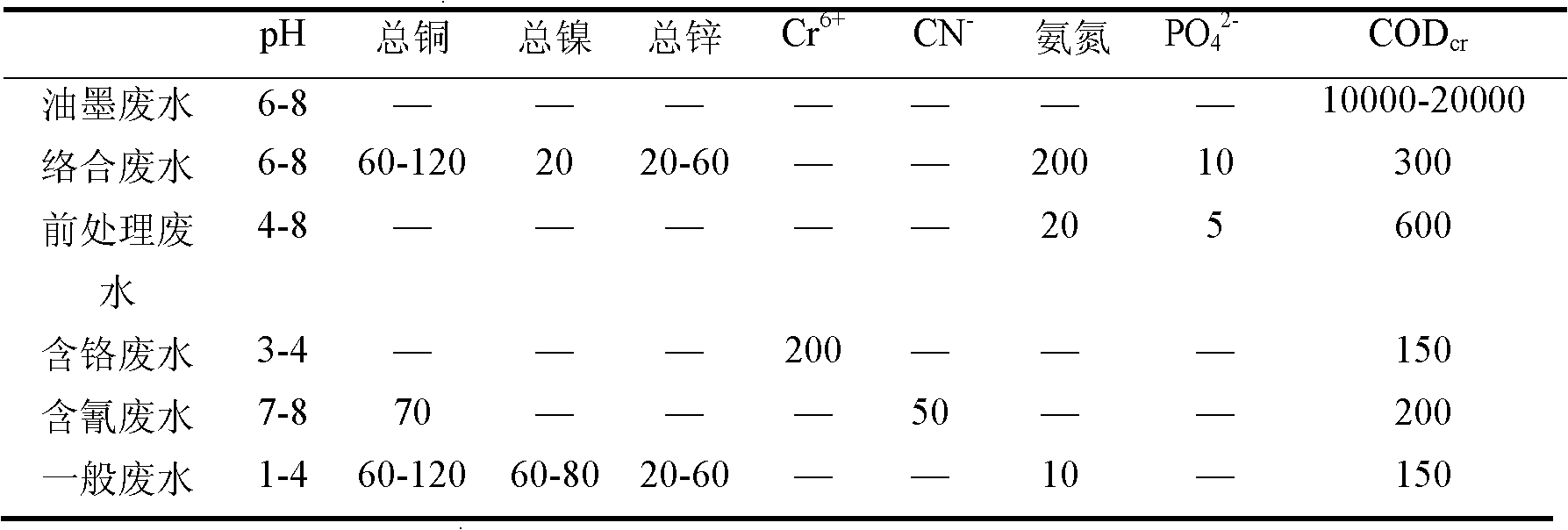

[0041] An electroplating industrial park in Shenzhen contains various types of electroplating, and its daily sewage discharge is 5,000 tons. The original wastewater treatment process is chemical precipitation method + biochemical treatment method. After the cyanide-containing wastewater undergoes cyanide breaking and the chromium-containing wastewater undergoes chromium reduction, it will be adjusted together with the comprehensive wastewater by adjusting the pH value and adding coagulants, polymer coagulants, etc. Metal ions, suspended solids and COD are removed, and then enter the biochemical pool for aerobic treatment to further remove COD. Make the effluent water quality meet the discharge standard.

[0042] In actual production, the quality of influent water fluctuates greatly in different production stages. For example, in the pretreatment stage of plating part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com