Ammonia removal method by ammonia nitrogen wastewater membrane integration

A technology of ammonia nitrogen wastewater and membrane integration, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., to achieve resource utilization, avoid secondary pollution, and achieve discharge standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

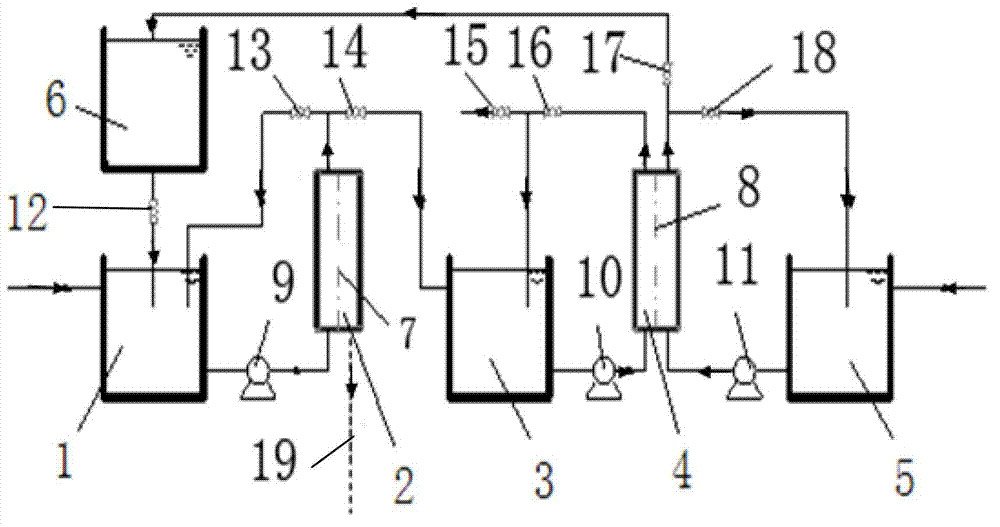

Image

Examples

Embodiment 1

[0037] Containing NH 4 The ammonia nitrogen value of CL solution is 6200mg / L, and the pH value of wastewater is 9.2. Use 0.2moL / L N a The pH value of the OH solution is always adjusted to 10, the temperature is 30°C, and after filtering through a 5 μm filter, the flow rate of the vacuum deamination circulation pump is controlled to be 30L / h, and the vacuum degree is controlled to be 100kPa. Vacuum deamination membrane components and membrane absorption deamination membrane components are selected from polypropylene laboratory-made components: the porosity is 40%, the outer diameter of the membrane filament is 0.3mm, the inner diameter is 0.22mm, and the pore diameter is 0.02-0.08μm. The area is 0.18m 2 , The effective length of the membrane module is 100mm. Within 3 hours of vacuum deamination, the ammonia nitrogen in wastewater dropped from 6200mg / L to 1116mg / L, and the efficiency of vacuum deamination reached 82%. The ammonia gas removed by vacuum is continuously absorbe...

Embodiment 2

[0041] A kind of wastewater containing ammonium sulfate, the water temperature is 45°C, the ammonia nitrogen concentration is about 15000mg / L, the wastewater treatment capacity is 8 tons / hour, the pH value of the wastewater is 4.5, and the membrane integrated deamination process is used to remove ammonia. Construct one vacuum deamination circulation tank with an effective volume of 200 tons, one membrane absorption circulation tank with an effective volume of 40 tons, one absorbent circulation tank and one absorbent buffer tank with an effective volume of 10 tons.

[0042] First introduce the waste water into the vacuum deamination circulation tank, adjust the pH to 10.5-11 in the circulation tank with 30% (W / W, mass concentration) NaOH solution, and keep it, control the water temperature at 50°C, and use vacuum deamination The circulation pump pumps the ammonia nitrogen wastewater into the vacuum degassing membrane module system, which is filtered by 10 microns and 5 microns r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com