Refining method for reducing steel ladle lining erosion

A ladle and ladle lining technology, which is applied in the refining field of reducing ladle lining erosion, can solve the problems of ladle slag line erosion, increase in the number of foreign inclusions, serious problems, etc., to reduce erosion, reduce the content of foreign inclusions, and improve the life of the ladle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The refining method for reducing ladle lining corrosion adopts the following specific processes.

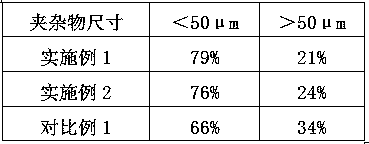

[0022] During the refining process of aluminum-containing steel SWRCH22A in LF furnace, the types and specific additions of materials are: lime 4.6kg / ton steel, fluorite 1.0kg / ton steel, pre-melted refining slag 1.6kg / ton steel, calcium carbide 0.67kg / ton per ton of steel, aluminum powder 0.64kg / ton of steel, magnesia 1.3kg / ton of steel. After the refining process, the temperature of the molten steel and the refining slag out of the station were sampled and tested for the main components. The specific results were (wt): CaO 53.62%, SiO 2 4.35%, Al 2 o 3 26.83%, MgO 12.04%, FeO+MnO 0.92%, molten steel temperature 1705°C. The finished cast slab of this embodiment was tested for inclusions, and the specific test results are shown in Table 1.

Embodiment 2

[0023] Embodiment 2: The refining method for reducing ladle lining corrosion adopts the following specific processes.

[0024] During the refining process of aluminum-containing steel SWRCH22A in the LF furnace, the types and specific additions of materials are: lime 4.9kg / ton steel, fluorite 1.06kg / ton steel, pre-melted refining slag 1.6kg / ton steel, calcium carbide 0.76kg / ton per ton of steel, aluminum powder 0.5kg / ton of steel, magnesia 1.6kg / ton of steel. After the refining process, the temperature of the molten steel and the refining slag out of the station were sampled and tested for the main components. The specific results were (wt): CaO 52.36%, SiO 2 5.14%, Al 2 o 3 27.42%, MgO 13.0%, FeO+MnO 0.89%, molten steel temperature 1702°C. The finished cast slab of this embodiment was tested for inclusions, and the specific test results are shown in Table 1.

Embodiment 3

[0030] Embodiment 3: The refining method for reducing ladle lining corrosion adopts the following specific processes.

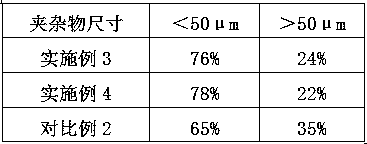

[0031] During the refining process of H08A steel in LF furnace, the types and specific additions of materials are: lime 5.5kg / ton steel, fluorite 1.2kg / ton steel, pre-melted refining slag 2.0kg / ton steel, calcium carbide 0.72kg / ton steel , aluminum powder 0.68kg / ton steel, magnesia 1.4kg / ton steel. After the refining process, the temperature of the molten steel and the refining slag out of the station were sampled and tested for the main components. The specific results were (wt): CaO 56.27%, SiO 2 3.94%, Al 2 o 3 24.33%, MgO 12.51%, FeO+MnO 0.93%, molten steel temperature 1699°C. The finished casting slab of this embodiment was inspected for inclusions, and the specific inspection results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com