Electro-adsorption desalination method for saline wastewater

A salt-containing wastewater, electro-adsorption technology, applied in separation methods, dispersed particle separation, etc., can solve problems such as the influence of electro-adsorption efficiency, the reduction of electro-adsorption efficiency, and the increase of concentration difference between the water inlet and the water outlet, so as to achieve a reduction balance. Adsorption time, saving electrode material, uniform ion distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

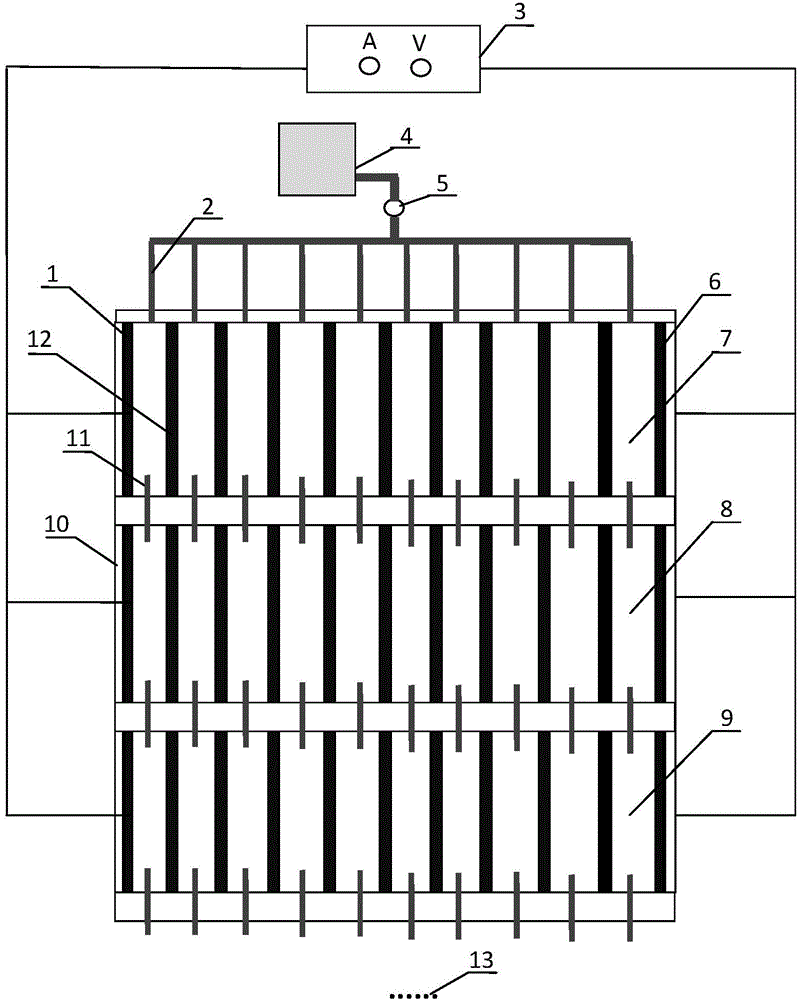

[0021] Such as figure 1 As shown, the electric adsorption device constructed is composed of brine distribution pool 4, 1# stable adsorption pool group 7, 2# stable adsorption pool group 8, 3# stable adsorption pool group constant flow pump 9, N# stable adsorption pool group 13. A total of 15 stable adsorption pool groups, as well as insulating water inlet pipe 2, insulating frame 10, single-sided anode electrode plate 1, single-sided cathode electrode plate 6, double-sided electrode plate 12, insulating channel 11 and regulated DC power supply Composition 3, the single-sided positive electrode plate, single-sided negative electrode plate and double-sided electrode plate are all made of coconut shell activated carbon powder doped with conductive acetylene black and binder, loaded on a titanium current collector, and the single-sided positive electrode plate The plate and the single-sided cathode electrode plate are a pair, length × width = 10 × 8cm, arranged on both sides of th...

Embodiment 2

[0023] Such as figure 1As shown, the electric adsorption device constructed is composed of brine distribution pool 4, 1# stable adsorption pool group 7, 2# stable adsorption pool group 8, 3# stable adsorption pool group constant flow pump 9, N# stable adsorption pool group 13. A total of 15 stable adsorption pool groups, as well as insulating water inlet pipe 2, insulating frame 10, single-sided anode electrode plate 1, single-sided cathode electrode plate 6, double-sided electrode plate 12, insulating channel 11 and regulated DC power supply Composition 3, the single-sided positive electrode plate, single-sided negative electrode plate and double-sided electrode plate are all made of coconut shell activated carbon powder doped with conductive acetylene black and binder, loaded on a titanium current collector, and the single-sided positive electrode plate The plate and the single-sided cathode electrode plate are a pair, length × width = 10 × 8cm, arranged on both sides of the...

Embodiment 3

[0025] Such as figure 1 As shown, the electric adsorption device constructed is composed of brine distribution pool 4, 1# stable adsorption pool group 7, 2# stable adsorption pool group 8, 3# stable adsorption pool group constant flow pump 9, N# stable adsorption pool group 13. A total of 15 stable adsorption pool groups, as well as insulating water inlet pipe 2, insulating frame 10, single-sided anode electrode plate 1, single-sided cathode electrode plate 6, double-sided electrode plate 12, insulating channel 11 and regulated DC power supply Composition 3, the single-sided positive electrode plate, single-sided negative electrode plate and double-sided electrode plate are all made of coconut shell activated carbon powder doped with conductive acetylene black and binder, loaded on a titanium current collector, and the single-sided positive electrode plate The plate and the single-sided cathode electrode plate are a pair, length × width = 10 × 8cm, arranged on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com