Quantum dot optical film of multi-layer structure, and preparation method and application thereof

A technology of quantum dot film and quantum dot layer, which is applied in optics, optical components, nonlinear optics, etc., and can solve problems such as the reduction of quantum dot luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

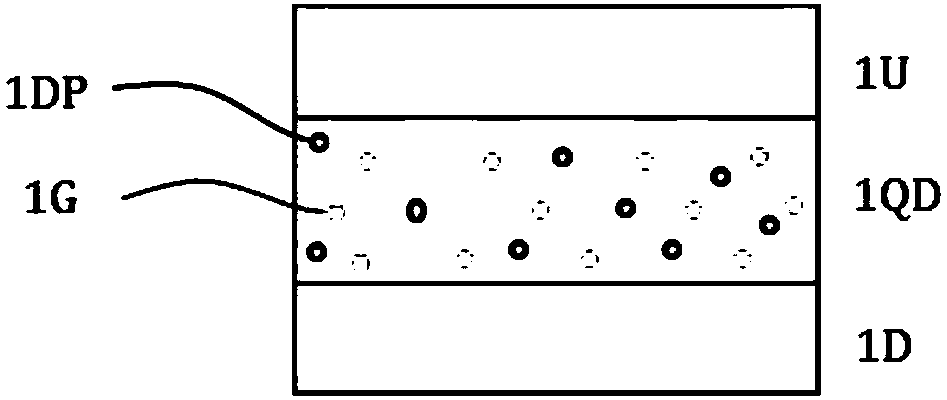

[0032] Multilayer structure quantum dot film with PET separation layer

[0033] 2 parts of light-diffusing particles (diffusion powder EL202, purchased from Yongqi Materials, the same as the light-diffusing particles in the examples and comparative examples described later) were dispersed into 20 parts of polymerization containing acrylic resin, epoxy resin and photoinitiator In the material (UV adhesive BTW-504-33, purchased from Betley, the polymer material in the following examples and comparative examples is the same), the disperser (Dragon Lab OS20-S) rotating speed is 1800rpm, The diameter of the turntable is 30mm, and the dispersion time is 10min. Repeat the above steps to obtain another part of the same mixture. Then, in the obtained mixture respectively, add 1.5 parts of green quantum dot mixed solution (provided by Tianjin Nanocomy, peak position 520nm) and 0.5 part of red quantum dot mixed solution (provided by Tianjin Nanocomy, peak position 625nm), respectively mi...

Embodiment 2

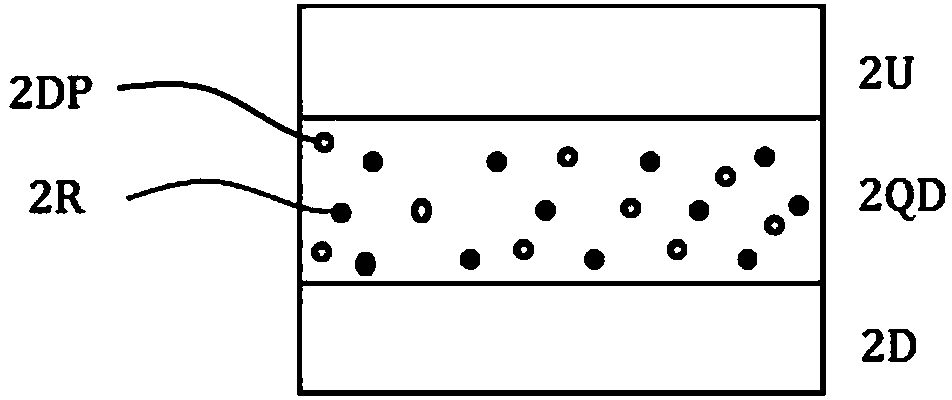

[0049] Multilayer structure quantum dot film with low refractive index spacer layer (air medium)

[0050] Disperse 2 parts of light-diffusing particles into 20 parts of polymer materials containing acrylic resin, epoxy resin and photoinitiator, the speed of the disperser (Dragon Lab OS20-s) is 1800rpm, the diameter of the turntable is 30mm, and the dispersion time is 10min. Repeat the above Step to obtain another portion of the same mixture. Then, to the respective obtained mixtures, add 1.5 parts of green quantum dot mixed solution (provided by Tianjin Nanocomy, peak position 520nm) and 0.5 part of red quantum dot mixed solution (provided by Tianjin Nanocomy, peak position 625nm), respectively mix to form green And red quantum dot UV curing glue. The two kinds of glue were respectively coated on a 75 μm thick PET base film, and after laminating another 75 μm thick PET base film, they were cured under 365 nm UV light to obtain two single-layer quantum dot films. In this embo...

Embodiment 3

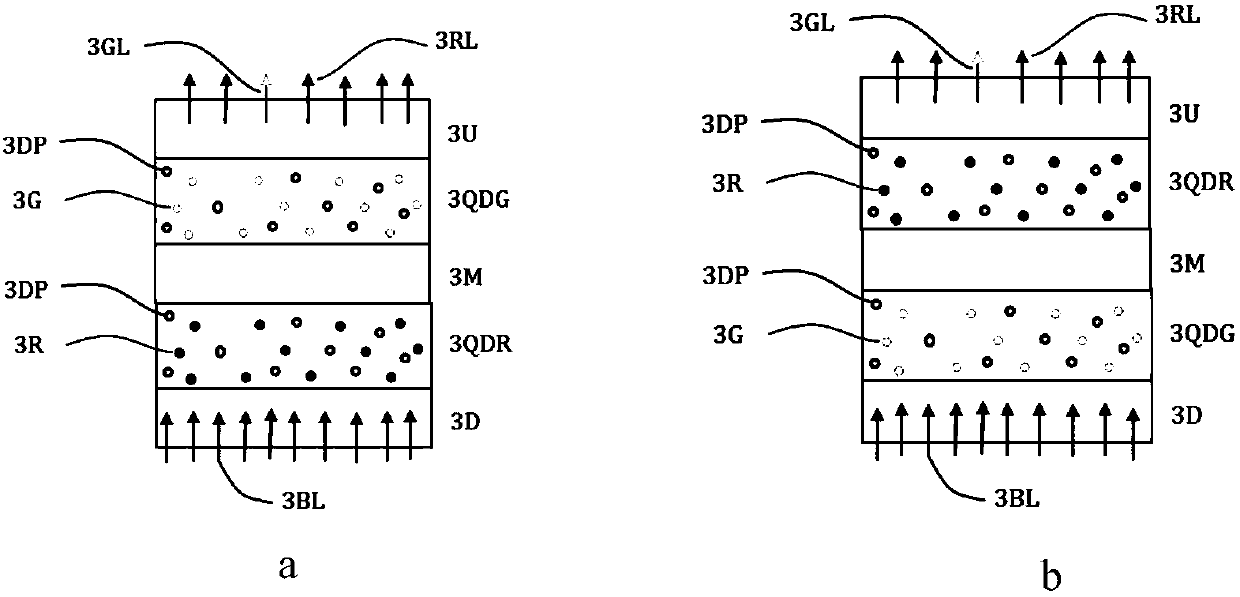

[0054] Multilayer structure quantum dot film with dichroic mirror

[0055] A multilayer quantum dot film with red and green quantum dot layers separated by a dichroic mirror capable of 100% reflecting green light in a certain incident direction. The incident angle of the dichroic mirror used in this embodiment is 45°, the thickness is 6.5 mm, and the diameter is 30 mm. Since the dichroic mirror used is relatively thick and small, it is impossible to directly coat the film on its surface. We first made a single-layer green or red quantum dot film to carry out this experiment. Disperse 1 part of light-diffusing particles into 20 parts of polymer materials containing acrylic resin, epoxy resin and photoinitiator, the speed of the disperser (Dragon Lab OS20-S) is 1200rpm, the diameter of the turntable is 30mm, and the dispersion time is 10min. Repeat the above steps Obtain another portion of the same mixture. Then, add 1.0 parts of green quantum dot mixed solution (provided by T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com