Improved type alternated technique for wastewater treatment of activated sludge process and equipment

A technology of activated sludge method and sewage treatment, which is applied in water/sludge/sewage treatment, biological water/sewage treatment, sustainable biological treatment, etc. It can solve the problems of compactness and intensification of the unfavorable integrated reaction tank and increase the intake pump. problems such as the operating cost of the room and the effective water depth limit of the reaction tank, to achieve the effect of increasing the effective activated sludge ratio, quick sludge communication, and alleviating the contradiction between the bacterial phase ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

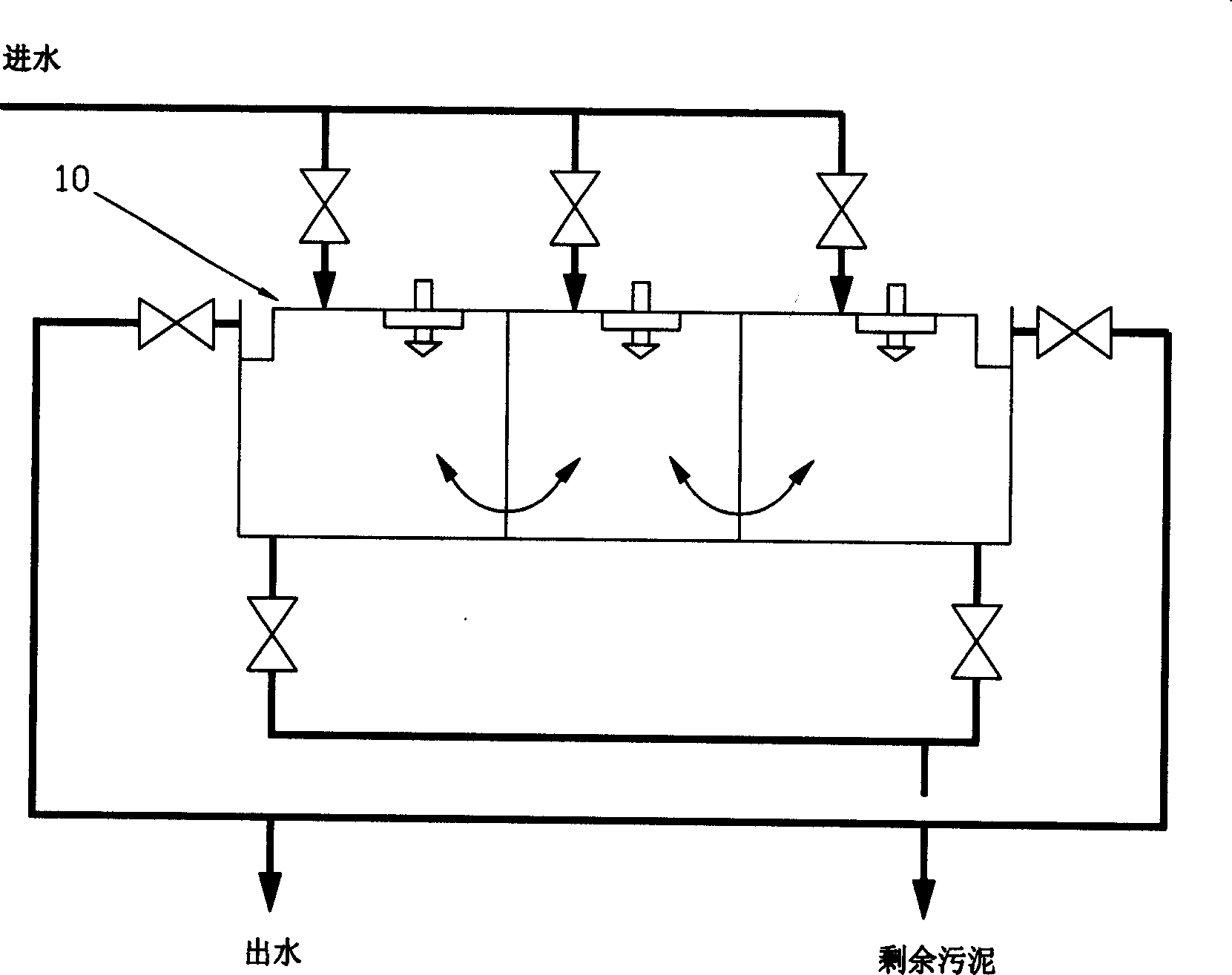

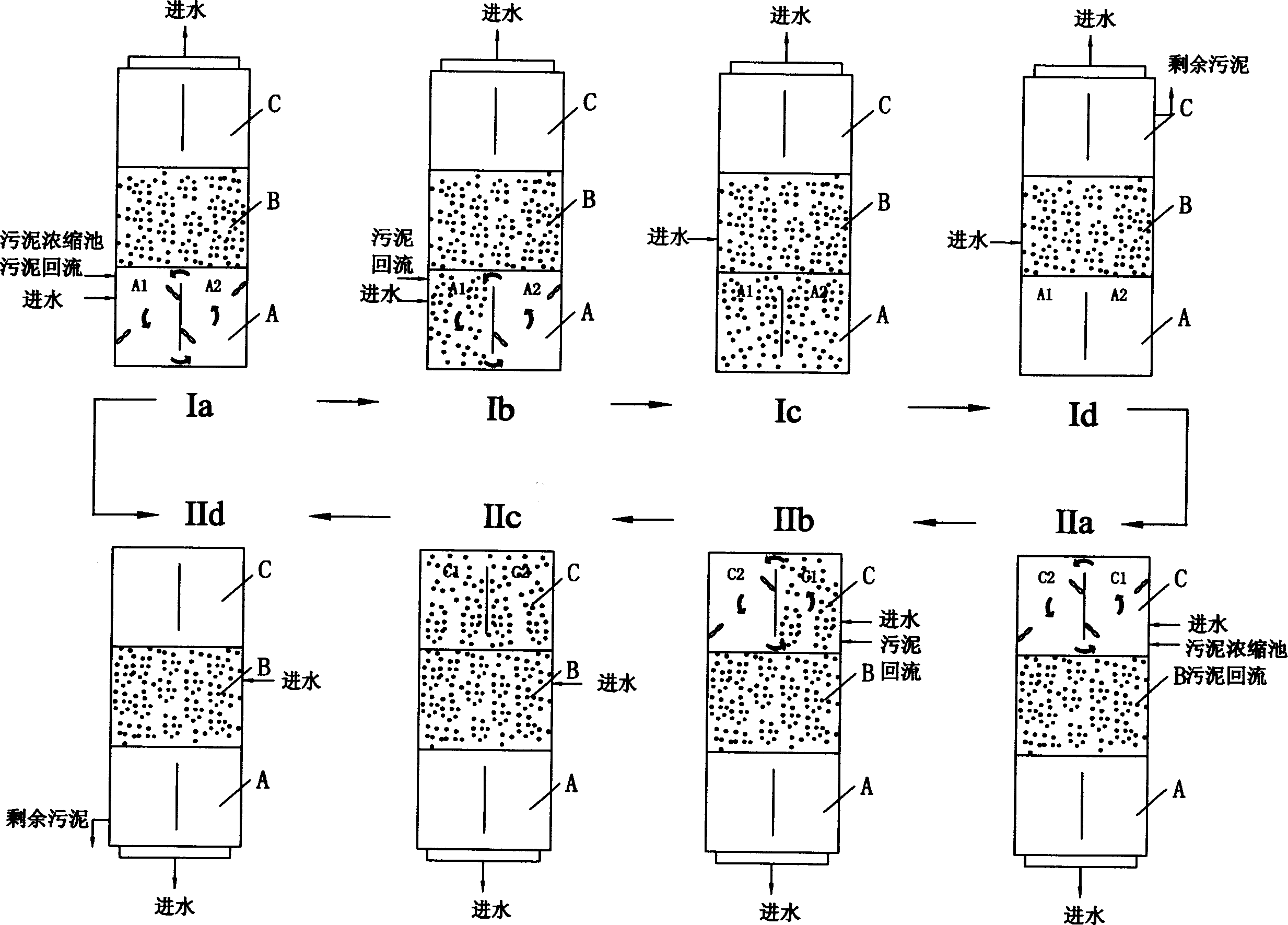

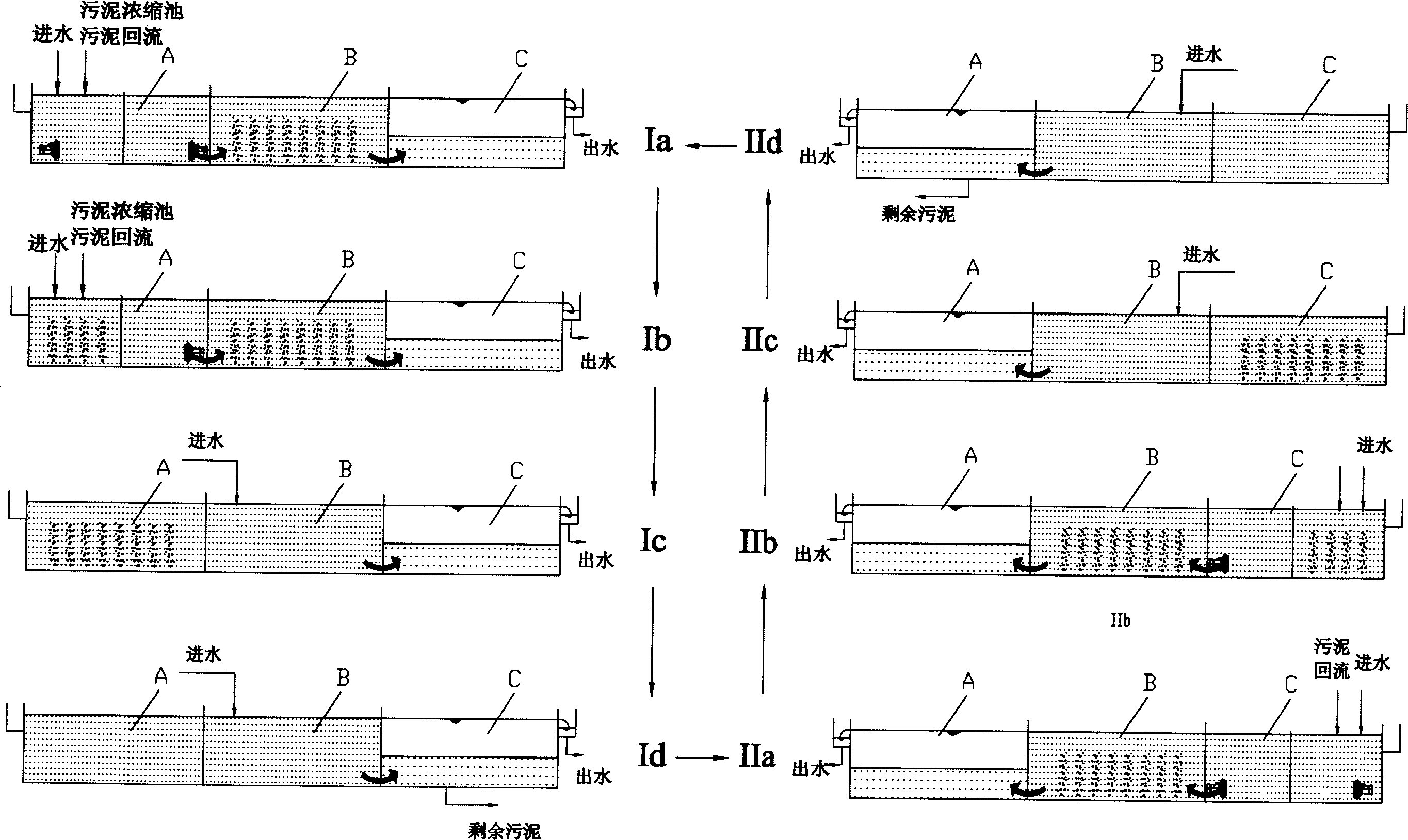

[0043] see figure 2 , image 3, the improved alternating activated sludge sewage treatment process of the present invention, the first main stage (2.0~6.0hr): be divided into Ia and Ib two stages, wherein, Ia stage (1.0~3.0hr, anaerobic grid / deficiency Oxygen grid stirring): The sewage first enters the A pool with a middle partition wall. Under the action of the agitator, at the water inlet point, the circulating mixed liquid and the incoming water can form a local area with a high sludge load, resulting in In the state of anaerobic biological phosphorus release, the mixed solution after staying in the anaerobic grid A1 is circulated to the anoxic grid A2 on the other side of the partition wall for anoxic denitrification, so that the nitrate content of the circulating mixed solution returned to the anaerobic grid is reduced , it is beneficial for phosphorus accumulating bacteria to absorb and rapidly degrade BOD and release phosphate under the dominant conditions. In additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com