Display panel and preparation method thereof

A technology for display panels and substrates, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve problems that affect display effects and that heat cannot be discharged reasonably and effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

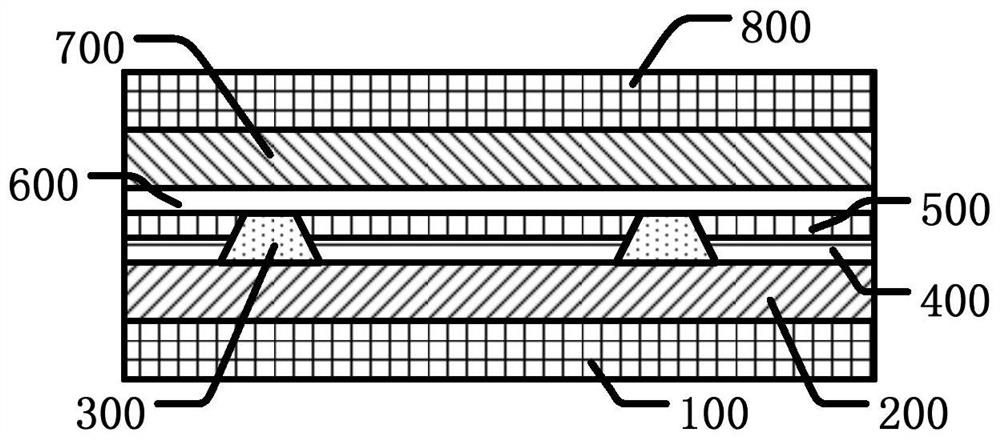

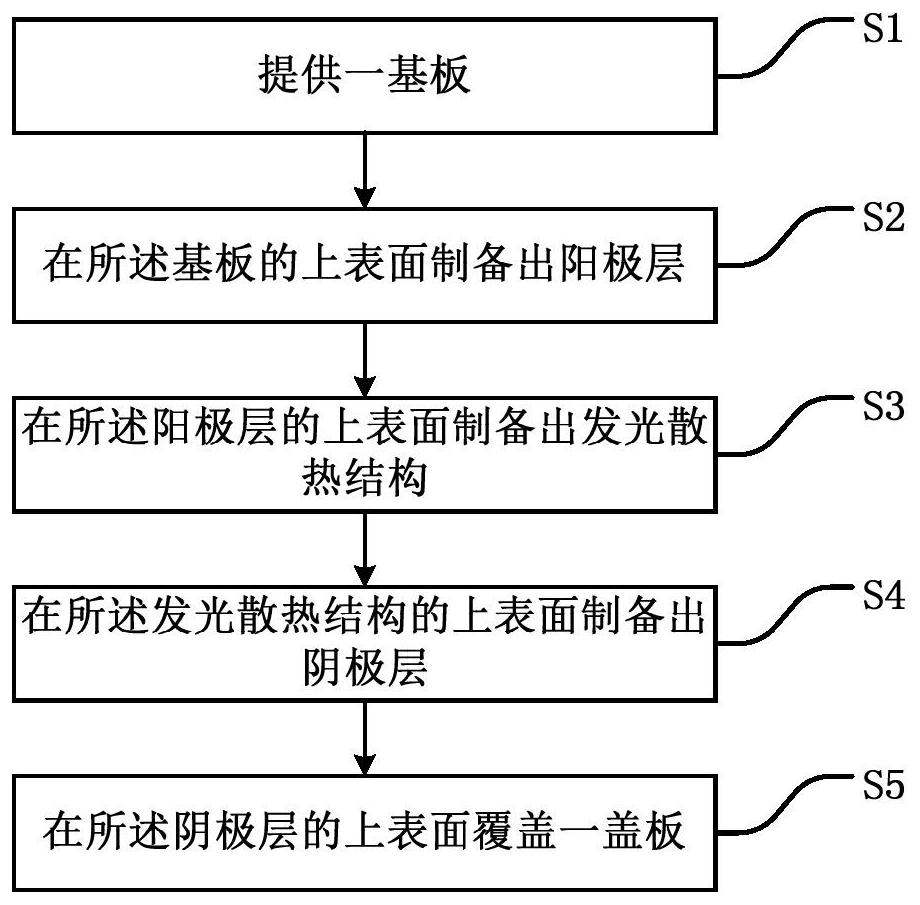

[0034] like figure 2 As shown, this embodiment provides a display panel, including: a substrate 1 , an anode layer 2 , a light emitting and heat dissipation structure 3 , a cathode layer and a cover plate 5 .

[0035] The substrate 1 is generally an array substrate, and the array substrate includes a base substrate, a thin film transistor, an insulating film layer, etc., which will not be described in detail here.

[0036] The anode layer 2 is arranged on the upper surface of the substrate 1, and the material of the anode layer 2 is generally a metal material, which has good electrical conductivity and performance. The anode layer 2 is used to provide circuit support for the light-emitting heat dissipation layer 3 .

[0037] The light-emitting and heat-dissipating structure 3 is arranged on the upper surface of the anode layer 2 to realize the light-emitting function and have a good heat-dissipating effect. The light-emitting heat dissipation layer 3 includes a pixel defini...

Embodiment 2

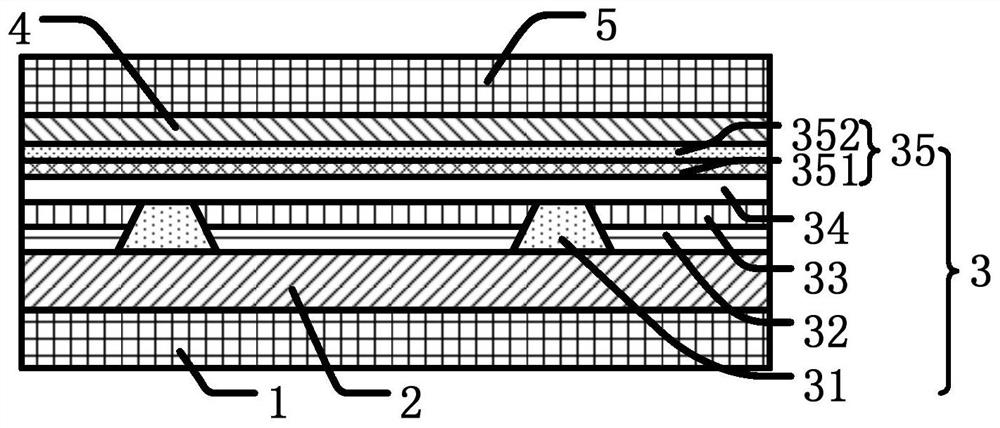

[0068] like Figure 6 As shown, this embodiment provides a display panel, including: a substrate 1 , an anode layer 2 , a light emitting and heat dissipation structure 3 , a cathode layer and a cover plate 5 .

[0069] The substrate 1 is generally an array substrate, and the array substrate includes a base substrate, a thin film transistor, an insulating film layer, etc., which will not be described in detail here.

[0070] The anode layer 2 is arranged on the upper surface of the substrate 1, and the material of the anode layer 2 is generally a metal material, which has good electrical conductivity and performance. The anode layer 2 is used to provide circuit support for the light-emitting heat dissipation layer 3 .

[0071] The light-emitting and heat-dissipating structure 3 is arranged on the upper surface of the anode layer 2 to realize the light-emitting function and have a good heat-dissipating effect. The light emitting and heat dissipation layer 3 includes a heat dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com