Adhesive and electrochemical device using adhesive

A technology of adhesives and tougheners, applied in the direction of adhesives, adhesive types, polymer adhesive additives, etc., can solve the problem of high viscosity of the system, achieve long-term high and low temperature resistance and heat and humidity shock, excellent processability, improve viscosity The effect of connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

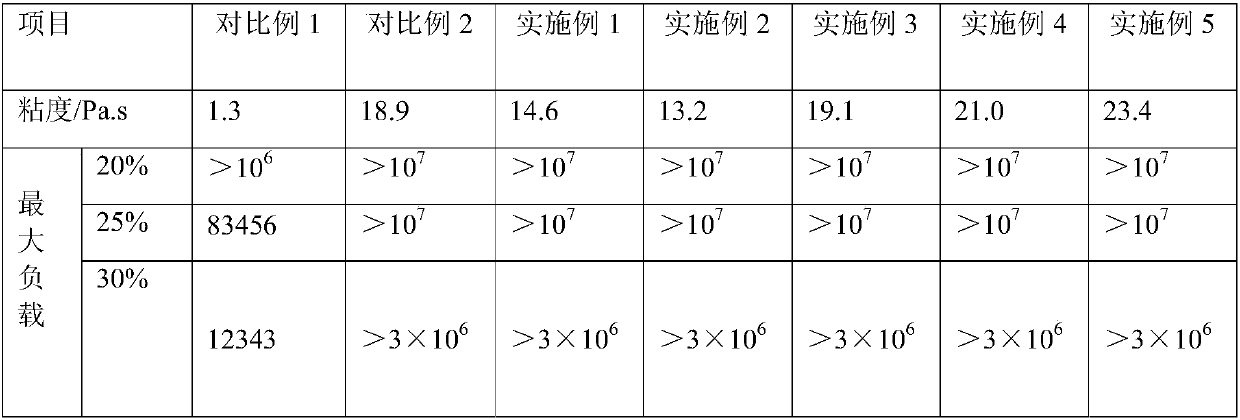

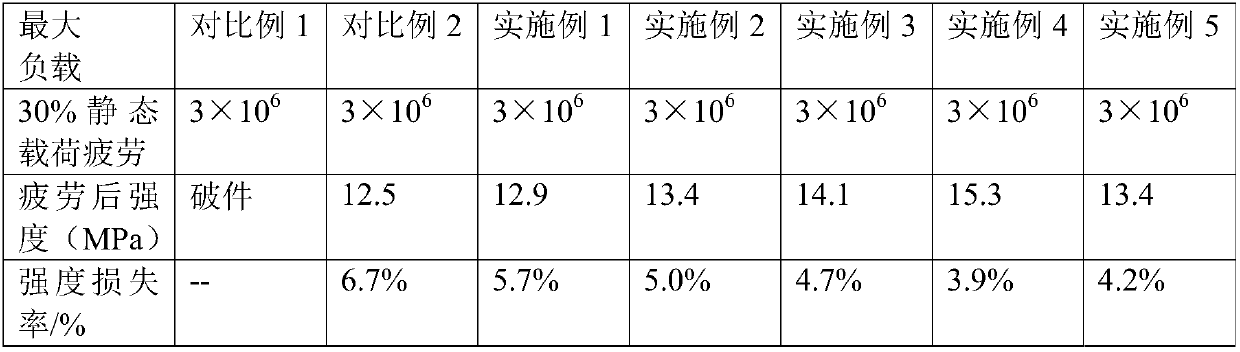

Examples

preparation example Construction

[0024] In the preparation method of the adhesive of the present invention, the following components are uniformly mixed by weight: 100 parts of epoxy resin, 5-30 parts of hyperbranched polysiloxane containing epoxy functional groups, 5-50 parts of toughening agent, 1-100 parts of filler, 2-50 parts of amine curing agent and 0.1-1 part of curing accelerator. During the mixing process, it can be kept heated to a certain temperature.

[0025] The device according to the second aspect of the present invention comprises a fiber-reinforced composite material element and a metal element, and the fiber-reinforced composite material element and the metal element are integrated by the above-mentioned adhesive.

Embodiment 1

[0027] (1) Under stirring conditions, after adding 45.00g of γ-glycidyl etheroxypropyltrimethoxysilane, 5.15g of deionized water and 0.09g of tetramethylammonium hydroxide (20% aqueous solution) into the three-necked flask, the Reflux at a constant temperature for 2 hours to obtain solution A;

[0028] (2) Under stirring conditions, dissolve 30.89g of trimethylchlorosilane in 54.00mL of methanol to obtain solution B;

[0029] (3) Under the conditions of stirring and nitrogen protection, solution B was poured into solution A at 60° C., and after constant temperature reflux at 60° C. for 6 hours, the crude product was obtained after vacuum distillation;

[0030] (4) After the crude product is dissolved in dichloromethane, the insoluble matter is filtered off, and after vacuum distillation and vacuum drying, the hyperbranched silicone resin containing the active functional group is obtained containing the epoxy functional group;

[0031] (5) by weight, 100g bisphenol A type epox...

Embodiment 2

[0033] By weight, 100g cycloaliphatic epoxy resin, the hyperbranched silicone resin containing epoxy functional group prepared by step (4) in 30g embodiment one, 50g carboxylated nitrile rubber, 100g clay, 2g polyethylene polyamine Mix evenly with 0.1g of 2,4,6-tris(dimethylaminomethyl)phenol at a temperature of 90°C to obtain a high-performance epoxy resin structural adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com